Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

Understanding Facial Recognition PCB Assembly: The Backbone of Modern Security Technology

2026-02-22

Facial recognition technology has revolutionized how we approach security and identification, utilizing advanced algorithms and hardware to analyze and recognize human faces. At the heart of this technology lies a critical component: the Printed Circuit Board (PCB) assembly designed specifically for facial recognition systems. Understanding Facial Recognition PCB Assembly is essential for anyone involved in the electronics industry or interested in the future of security technology.

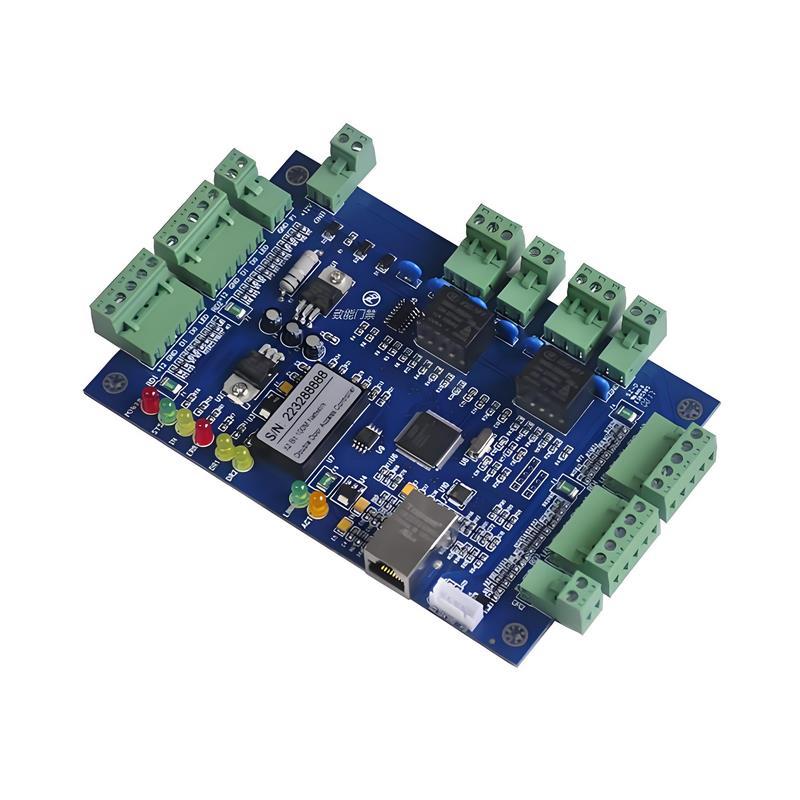

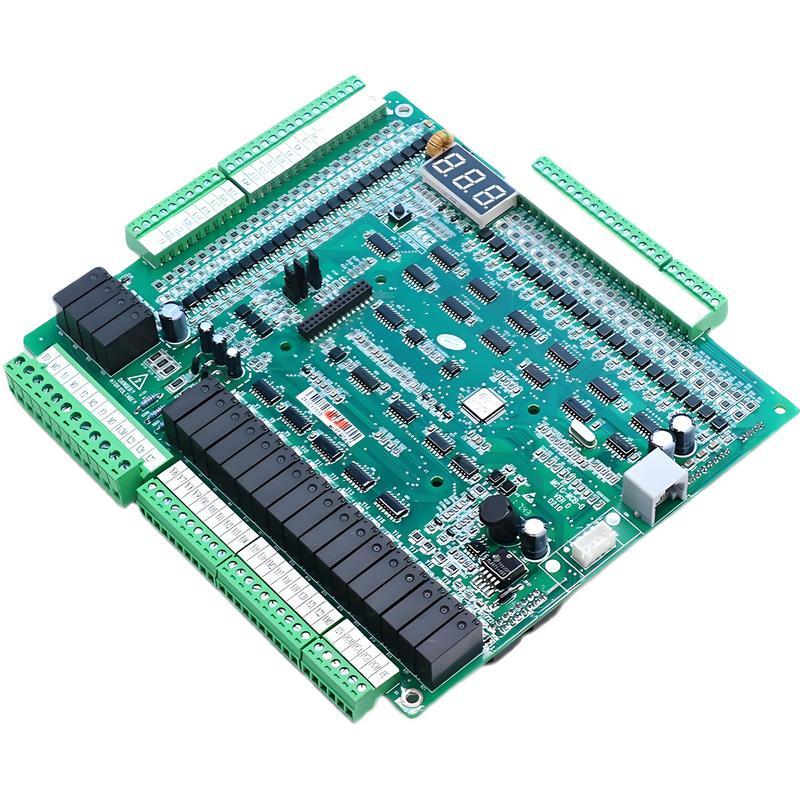

A Facial Recognition PCB Assembly serves as the groundwork for the sensors, processors, and communication systems that enable facial recognition devices to function effectively. These assemblies typically incorporate various electronic components such as microcontrollers, image sensors, and communication interfaces that work together to capture, process, and analyze facial images. The integration of these components in a PCB assembly is crucial for ensuring that the system operates efficiently and reliably.

One of the primary components of a Facial Recognition PCB Assembly is the image sensor. This sensor captures visual data, which is then processed through algorithms that identify and compare facial features. The efficiency of these algorithms largely depends on the quality of the PCB assembly. High-density interconnections and optimized layouts within the PCB can significantly enhance the performance of the facial recognition system.

Moreover, the design process for Facial Recognition PCB Assembly requires careful consideration of various factors, such as power consumption, thermal management, and signal integrity. These factors can greatly affect the overall performance of the facial recognition system. For instance, efficient power management ensures that the device operates smoothly without overheating, while proper signal integrity minimizes noise and improves data accuracy.

In addition to security applications, Facial Recognition PCB Assembly is increasingly finding its way into consumer electronics, such as smartphones and smart home devices. As users become more concerned about privacy and security, manufacturers are integrating facial recognition capabilities into their products to enhance user experiences. This trend has created a growing demand for specialized PCB assemblies that can support such advanced technologies.

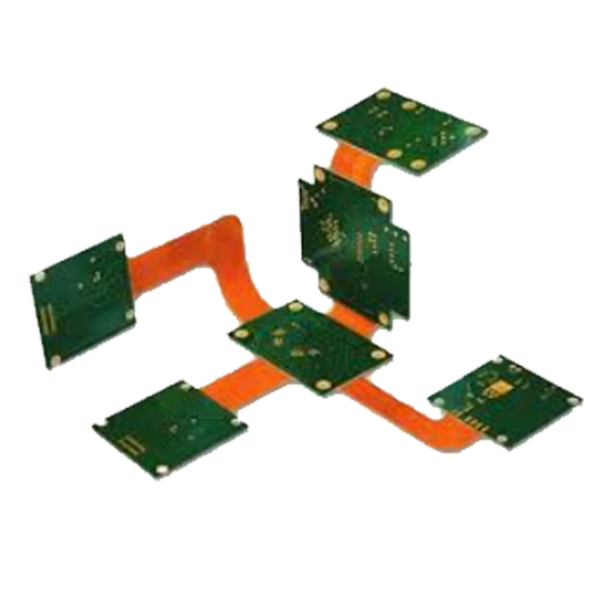

Moreover, advancements in manufacturing technology, such as automated assembly processes and the use of advanced materials, have significantly improved the production and reliability of Facial Recognition PCB Assemblies. These improvements have made it possible to create more compact and efficient designs that are essential for the ever-evolving landscape of electronic devices.

In conclusion, the importance of Facial Recognition PCB Assembly cannot be overstated. As technology continues to advance, the demand for reliable and efficient PCB assemblies that support facial recognition capabilities will only grow. Understanding the components and design considerations involved in this process is crucial for industry professionals and enthusiasts alike. By staying informed about these developments, stakeholders can better appreciate the role of Facial Recognition PCB Assembly in shaping the future of security and electronic devices.

A Facial Recognition PCB Assembly serves as the groundwork for the sensors, processors, and communication systems that enable facial recognition devices to function effectively. These assemblies typically incorporate various electronic components such as microcontrollers, image sensors, and communication interfaces that work together to capture, process, and analyze facial images. The integration of these components in a PCB assembly is crucial for ensuring that the system operates efficiently and reliably.

One of the primary components of a Facial Recognition PCB Assembly is the image sensor. This sensor captures visual data, which is then processed through algorithms that identify and compare facial features. The efficiency of these algorithms largely depends on the quality of the PCB assembly. High-density interconnections and optimized layouts within the PCB can significantly enhance the performance of the facial recognition system.

Moreover, the design process for Facial Recognition PCB Assembly requires careful consideration of various factors, such as power consumption, thermal management, and signal integrity. These factors can greatly affect the overall performance of the facial recognition system. For instance, efficient power management ensures that the device operates smoothly without overheating, while proper signal integrity minimizes noise and improves data accuracy.

In addition to security applications, Facial Recognition PCB Assembly is increasingly finding its way into consumer electronics, such as smartphones and smart home devices. As users become more concerned about privacy and security, manufacturers are integrating facial recognition capabilities into their products to enhance user experiences. This trend has created a growing demand for specialized PCB assemblies that can support such advanced technologies.

Moreover, advancements in manufacturing technology, such as automated assembly processes and the use of advanced materials, have significantly improved the production and reliability of Facial Recognition PCB Assemblies. These improvements have made it possible to create more compact and efficient designs that are essential for the ever-evolving landscape of electronic devices.

In conclusion, the importance of Facial Recognition PCB Assembly cannot be overstated. As technology continues to advance, the demand for reliable and efficient PCB assemblies that support facial recognition capabilities will only grow. Understanding the components and design considerations involved in this process is crucial for industry professionals and enthusiasts alike. By staying informed about these developments, stakeholders can better appreciate the role of Facial Recognition PCB Assembly in shaping the future of security and electronic devices.

Related news