Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

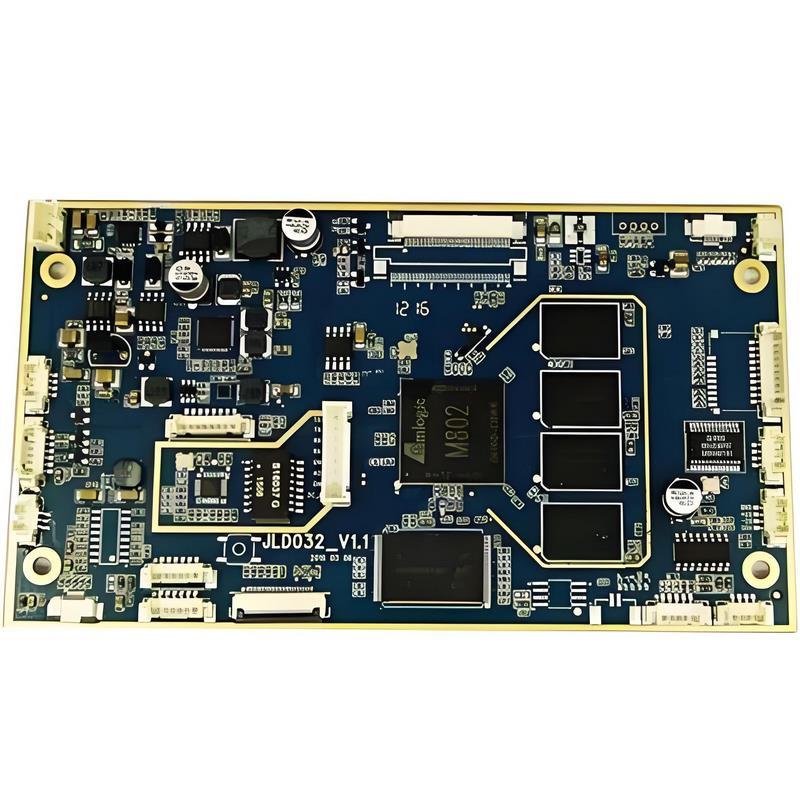

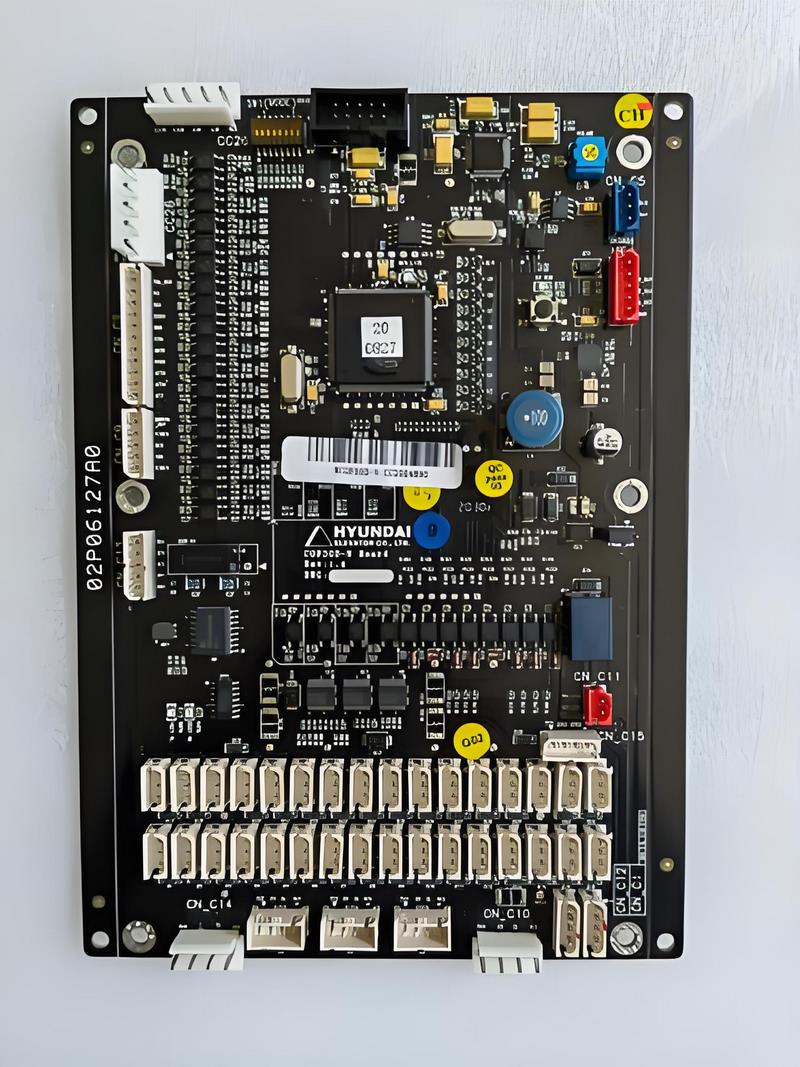

Elevator Control PCB Assembly

One-stop PCBA/EMS Intelligent Manufacturing Solution

Elevator Control PCB Assembly

The Role of PCBs in Elevator Control

Printed Circuit Boards (PCBs) are the essential backbone of modern elevator control systems, providing the critical platform for managing safety, movement, communication, and user interfaces. PCBs connect and coordinate the complex network of sensors, motor drivers, microcontrollers, and communication modules required to ensure smooth, reliable, and safe elevator operation.

1. Control Logic and Processing

PCBs host the microcontrollers or PLCs (Programmable Logic Controllers) that process input signals from buttons, sensors, and safety devices.

They execute control algorithms to manage elevator speed, acceleration, door operation, and floor selection.

2. Sensor and Feedback Integration

Elevator PCBs interface with various sensors such as position encoders, load sensors, door sensors, and emergency stop buttons.

Accurate sensor data ensures precise movement control and safety compliance.

3. Power Management and Motor Control

PCBs regulate power delivery to motors and brakes, including variable frequency drives (VFD) for smooth acceleration and deceleration.

Integrated power management circuits protect components from voltage spikes and ensure efficient energy use.

4. Communication and Networking

PCBs facilitate communication between elevator cabins, control rooms, and building management systems using wired or wireless protocols.

Real-time data exchange supports diagnostics, remote monitoring, and maintenance alerts.

5. User Interface and Safety Systems

The PCB controls displays, buttons, lighting, and alarm systems inside the elevator cabin.

Safety-critical features like emergency intercoms and fire recall systems are integrated on the PCB for reliability.

Key Components of Elevator Control PCB Assembly

Elevator control PCBs integrate a variety of specialized components to ensure safety, precision, and smooth operation. Each plays a vital role in managing signals, power, and communication throughout the system.

1. Microcontrollers / Programmable Logic Controllers (PLCs)

Serve as the brains of the system, executing control algorithms for elevator movement, door operation, and safety monitoring.

2. Power Management Modules

Include voltage regulators, DC-DC converters, and protection circuits to supply stable power to all components.

Manage power delivery to motors and braking systems.

3. Motor Drivers and Variable Frequency Drives (VFDs)

Control the speed and torque of elevator motors for smooth acceleration and deceleration.

Ensure energy-efficient operation and reduce mechanical wear.

4. Sensors and Feedback Interfaces

Position encoders, load sensors, door sensors, and emergency stop inputs provide real-time data for precise control and safety.

5. Communication Modules

Support protocols like RS485, CAN bus, Ethernet, or wireless connectivity to interface with building management systems and remote monitoring.

6. Display and User Interface Components

Control cabin displays, button panels, LED indicators, and audible alarms.

Integrate touchscreens or simple LED/LCD modules depending on the elevator design.

7. Safety and Emergency Circuits

Include circuits for emergency brakes, fire recall, intercom systems, and backup power management.

Often incorporate fail-safe designs and watchdog timers to ensure reliability.

8. Connectors and Interface Ports

Provide reliable connections for sensors, actuators, power supply, and external communication lines.

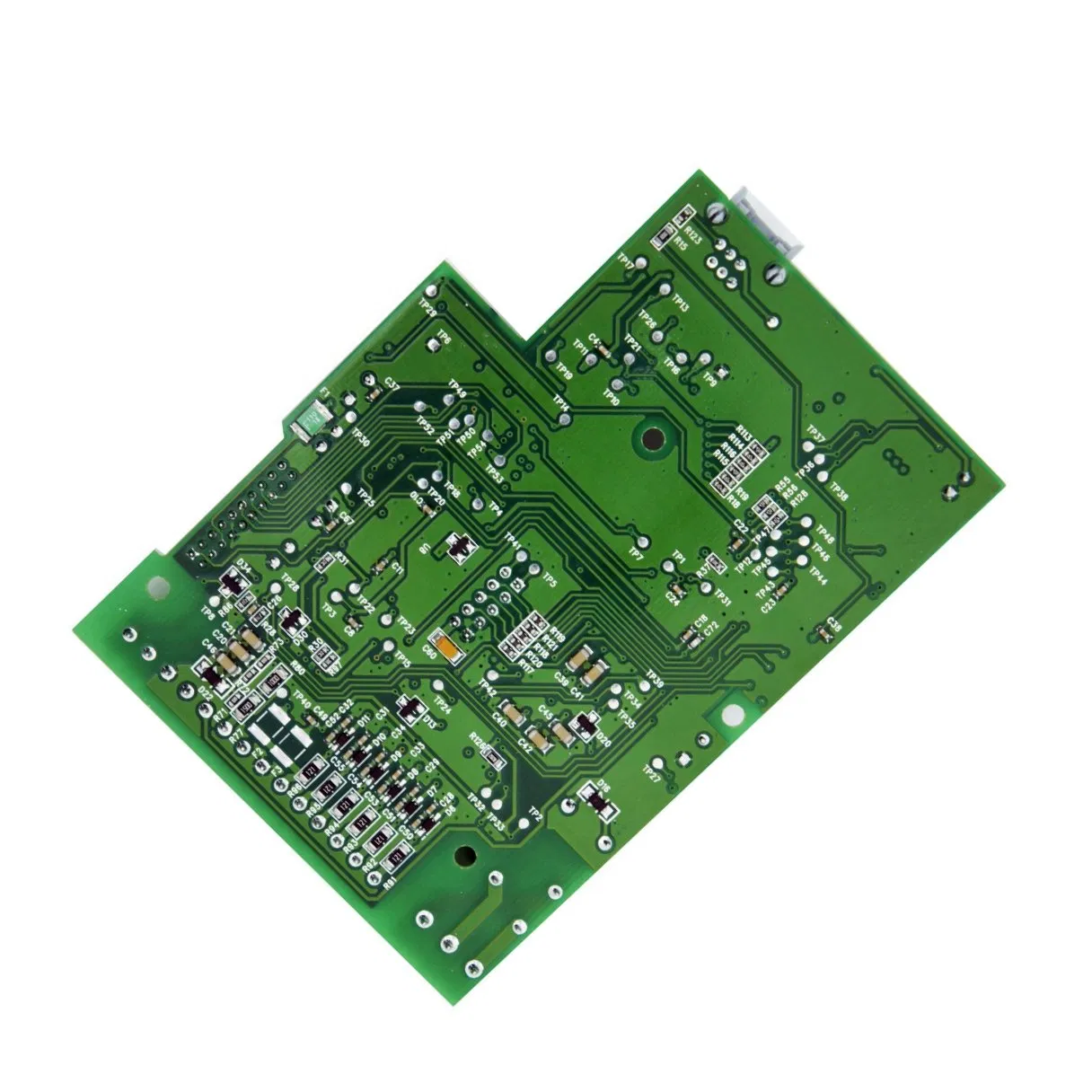

Materials and Technologies for Elevator Control PCB Assembly

Elevator control PCBs require materials and technologies that ensure reliability, safety, and long-term performance in often harsh operating environments. The selection of substrates, components, and assembly techniques directly impacts system stability and compliance with industry standards.

1. PCB Substrate Materials

High-TG FR-4 Laminates – Provide thermal stability and mechanical strength needed for high-power motor control circuits.

Polyimide and Flexible PCBs – Used in compact or curved control modules where space is limited.

2. Copper Thickness and Finishes

Heavy Copper Layers (2 oz or more) – Support high current loads for motor drivers and power circuits.

Surface Finishes: ENIG (Electroless Nickel Immersion Gold) or HASL (Hot Air Solder Leveling) for corrosion resistance and reliable solder joints.

3. Assembly Technologies

Surface Mount Technology (SMT) – Enables compact placement of microcontrollers, sensors, and communication ICs.

Through-Hole Technology (THT) – Used for power components, connectors, and mechanical robustness.

Selective Soldering and Wave Soldering – Applied for through-hole components to ensure strong joints.

4. Thermal Management

Thermal Vias and Copper Pours – Facilitate heat dissipation from high-power components like motor drivers and voltage regulators.

Heat Sinks and Thermal Pads – Attached to critical ICs to maintain safe operating temperatures.

5. EMI/EMC Mitigation

Shielding Layers and Ground Planes – Reduce electromagnetic interference in sensitive signal circuits.

Ferrite Beads and Filtering Components – Prevent noise propagation through power and signal lines.

6. Safety and Compliance

Use of flame-retardant materials and adherence to UL94 V-0 standards.

Integration of ESD protection devices and surge suppressors for enhanced system robustness.

Elevator Control PCB Assembly Process

The assembly of elevator control PCBs involves precise manufacturing and strict quality control to ensure safety, reliability, and optimal performance in elevator systems. The process includes the following key stages:

1. Design and Prototyping

• Develop detailed schematics and PCB layouts tailored for motor control, sensor integration, and communication requirements.

• Produce prototypes for validation and testing under simulated operating conditions.

2. Material Preparation

• Select high-TG laminates and heavy copper substrates to handle thermal and electrical loads.

• Prepare PCBs by cleaning and inspecting surface finishes for solderability.

3. Component Procurement and Inspection

• Source high-reliability microcontrollers, power modules, sensors, and connectors from certified suppliers.

• Perform incoming quality control to verify component authenticity and specifications.

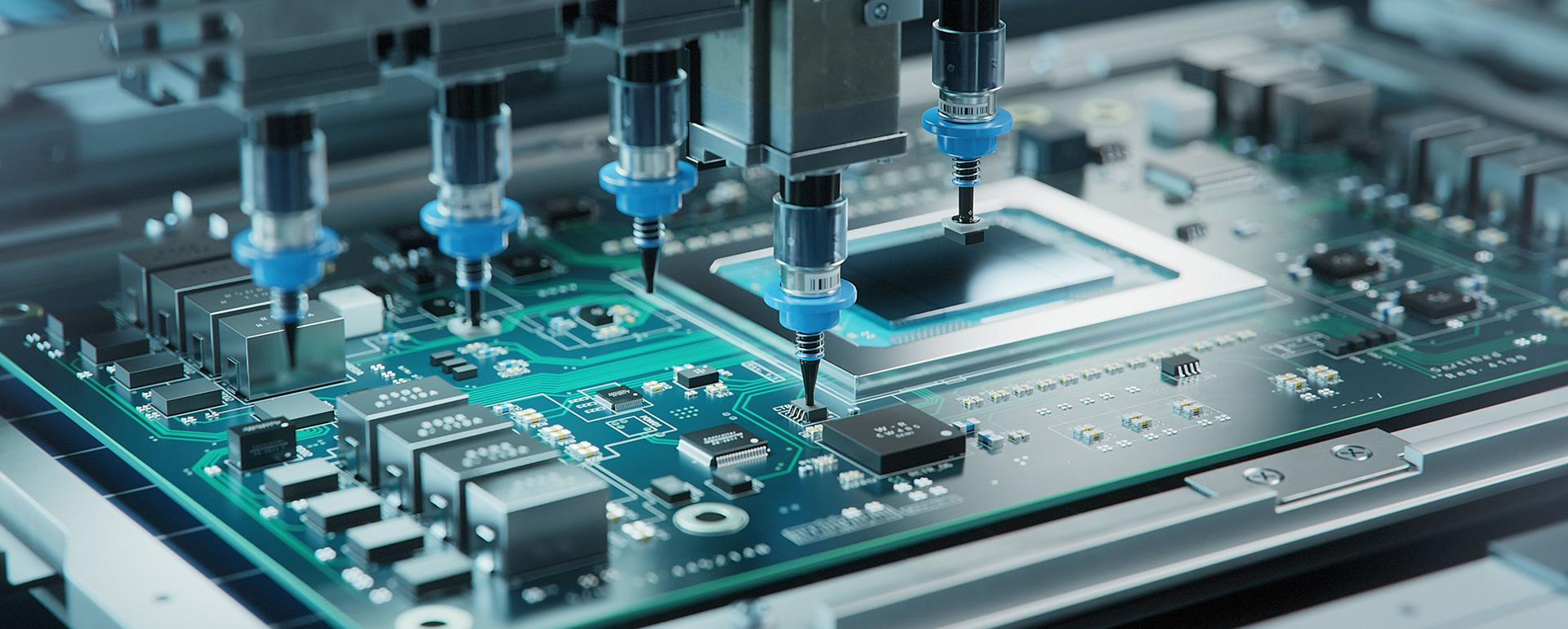

4. Component Placement

• Use automated pick-and-place machines for SMT components, including ICs, resistors, capacitors, and communication modules.

• Insert through-hole components like connectors and power devices manually or with selective automation.

5. Soldering

• Perform reflow soldering for SMT components, ensuring controlled thermal profiles to avoid damage.

• Use wave or selective soldering techniques for through-hole parts to guarantee strong mechanical and electrical connections.

6. Cleaning and Inspection

• Clean assembled PCBs to remove flux residues and contaminants.

• Conduct Automated Optical Inspection (AOI) and X-ray inspection to detect solder defects and component placement issues.

7. Functional Testing

• Execute In-Circuit Testing (ICT) and Functional Circuit Testing (FCT) to verify electrical performance and system functionality.

• Test motor control outputs, sensor inputs, communication interfaces, and safety circuits.

8. Environmental Stress Testing

• Subject PCBs to thermal cycling, vibration, and humidity tests to confirm durability and reliability under real-world conditions.

9. Final Assembly and Packaging

• Integrate PCBs into elevator control units or cabinets.

• Package with anti-static materials and secure for transportation.

Future Implications of Elevator Control PCB Assembly

As elevator technology advances towards smarter, safer, and more energy-efficient systems, the role of PCB assembly in elevator control will continue to evolve significantly. Key future trends and implications include:

1. Integration of IoT and Smart Connectivity

PCBs will increasingly support IoT-enabled features, allowing elevators to communicate in real time with building management systems for predictive maintenance and enhanced user experience.

Wireless connectivity modules and embedded sensors will be standard, improving diagnostics and operational efficiency.

2. Enhanced Safety and Redundancy

Advanced PCB designs will incorporate multiple safety layers, fail-safe mechanisms, and redundant circuits to meet stricter regulations and ensure passenger safety.

Real-time monitoring and emergency response capabilities will be embedded directly on control PCBs.

3. Energy Efficiency and Green Technologies

PCB assemblies will support energy-saving motor control algorithms and regenerative braking systems, contributing to greener building operations.

Use of advanced materials and thermal management solutions will improve power efficiency and component lifespan.

4. Miniaturization and Modular Designs

Compact, modular PCB assemblies will allow easier upgrades and customization of elevator control units, reducing downtime and maintenance costs.

Flexible PCB technologies may be adopted for better space utilization in compact elevator cabins and control panels.

5. Advanced Manufacturing Techniques

Adoption of Industry 4.0 practices including AI-driven quality control, automated testing, and real-time production monitoring will increase yield and reduce defects.

Use of additive manufacturing and advanced PCB materials will enable more complex, reliable designs.

Conclusion

Printed Circuit Boards are the critical foundation of modern elevator control systems, enabling precise motor control, safety monitoring, and seamless communication. Through the use of advanced materials, robust assembly processes, and innovative technologies, elevator PCBs ensure reliable and efficient operation in diverse environments.

Looking ahead, the integration of smart connectivity, enhanced safety features, and energy-efficient designs will drive the evolution of elevator control PCBs. Manufacturers who adopt cutting-edge assembly techniques and materials will be well-positioned to support the next generation of intelligent, sustainable elevator systems.

Ready to Elevate Your PCB Projects to New Heights?

In today’s fast-evolving building technologies, reliable and intelligent elevator control systems are more critical than ever. Our expertise in precision PCB assembly, advanced materials, and rigorous quality assurance ensures your elevator control designs achieve peak performance, safety, and durability.

Partner with us to transform your elevator PCB concepts into dependable, innovative solutions that elevate user experience and building efficiency.