Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

Precision Instruments PCB Assembly

One-stop PCBA/EMS Intelligent Manufacturing Solution

Precision Instruments PCB Assembly

The Role of PCBs in Precision Instruments

Printed Circuit Boards (PCBs) are the backbone of modern precision instruments, providing the stable and reliable platform needed to integrate sensitive components, process signals, and maintain measurement accuracy. In applications ranging from laboratory equipment to medical devices, PCBs ensure that every signal is transmitted and processed with minimal noise or distortion.

1. Signal Integrity and Accuracy

Precision instruments rely on accurate signal transmission for measurements, analysis, and control.

High-quality PCBs use controlled impedance traces, optimized layouts, and low-loss materials to minimize signal degradation.

2. Sensor Integration

PCBs serve as the interface between precision sensors (temperature, pressure, optical, or biochemical) and the processing circuitry.

Multi-layer designs allow for dense sensor integration while maintaining isolation between sensitive analog and high-speed digital circuits.

3. Power Management

Stable and noise-free power distribution is essential for maintaining measurement accuracy.

PCBs integrate voltage regulation, filtering, and shielding to ensure a clean power supply for sensitive components.

4. Noise Reduction and Shielding

Precision devices often require PCBs with electromagnetic shielding, ground planes, and strategic component placement to reduce interference.

Techniques such as differential signal routing and guard traces help preserve signal clarity.

5. Mechanical Stability and Reliability

PCBs provide a rigid, vibration-resistant foundation that keeps components aligned and connections secure, even in demanding environments.

Conformal coatings and specialized laminates protect against moisture, dust, and temperature fluctuations.

6. Customization for Application-Specific Needs

PCBs can be tailored to meet the exact requirements of the instrument, including unusual form factors, mixed-signal layouts, or integration with displays and user interfaces.

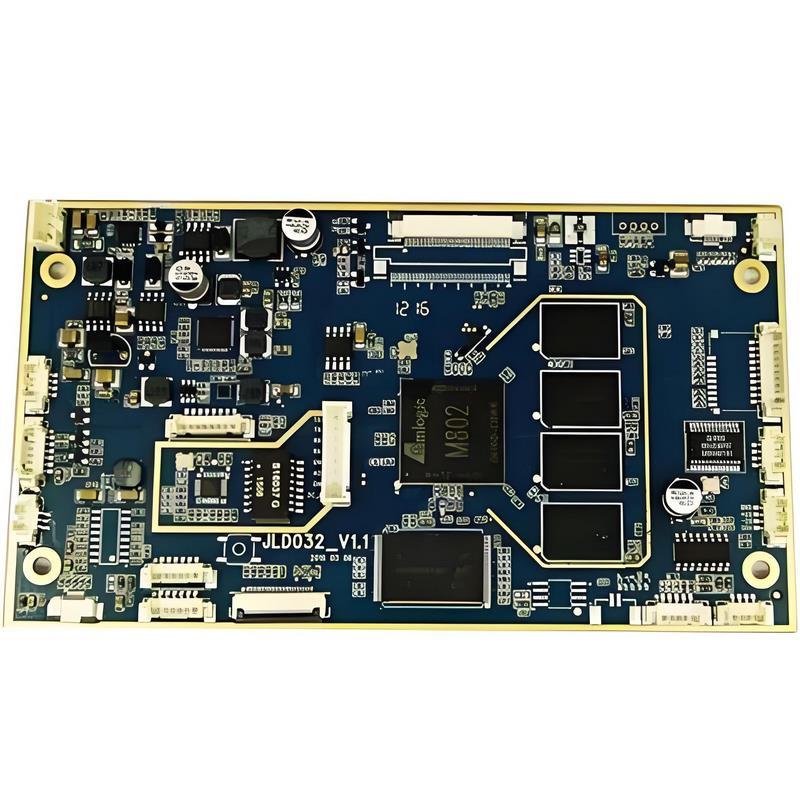

Key Components of Precision Instruments PCB Assembly

Precision instrument PCBs integrate a range of specialized components designed to ensure measurement accuracy, stability, and reliability. Each plays a critical role in processing and protecting sensitive signals.

1. Microcontrollers and Signal Processors

Act as the control center, executing data acquisition, processing, and output functions.

Examples: ARM Cortex-M series MCUs, DSPs for real-time signal analysis.

2. Precision Analog Components

Operational Amplifiers (Op-Amps): For signal conditioning, filtering, and amplification with minimal distortion.

Analog-to-Digital Converters (ADCs) & Digital-to-Analog Converters (DACs): Ensure high-resolution signal conversion for accurate measurements.

3. Sensor Interfaces

Connect the PCB to precision sensors (e.g., temperature, pressure, optical, biochemical).

Include filtering, impedance matching, and protection circuits to maintain data integrity.

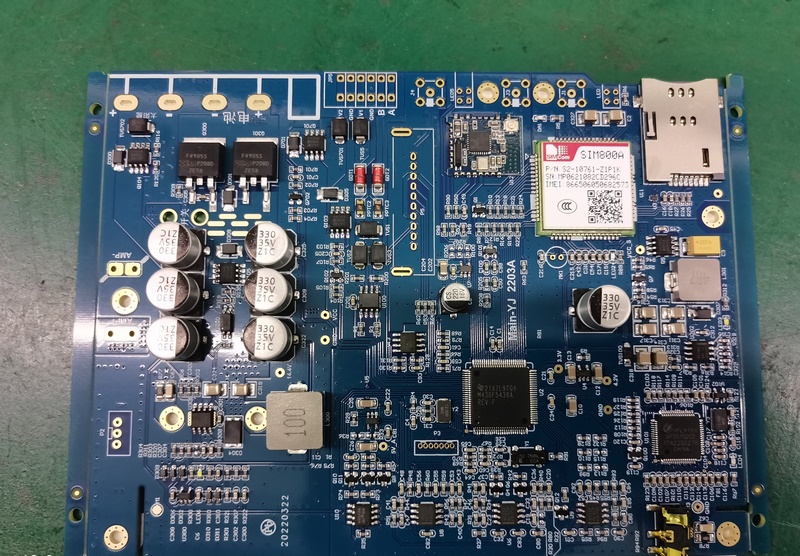

4. Power Management Modules

Provide clean, stable power through voltage regulators, low-dropout regulators (LDOs), and power filters.

Minimize electrical noise that can affect measurement accuracy.

5. Memory and Data Storage

Store calibration data, firmware, and measurement logs.

May include non-volatile memory (EEPROM, Flash) and high-speed RAM.

6. Communication Interfaces

Enable data transfer between the instrument and external systems.

Examples: USB, Ethernet, RS-485, CAN, wireless modules.

7. Protection Components

Safeguard sensitive electronics from electrostatic discharge (ESD), surges, and reverse polarity.

Common devices: TVS diodes, fuses, transient suppressors.

8. Thermal Management Features

Heat sinks, copper pours, and thermal vias for components that generate heat during operation.

Materials and Technologies for Precision Instruments PCB Assembly

PCBs for precision instruments demand materials and assembly technologies that can maintain high signal integrity, mechanical stability, and long-term reliability. The choice of materials and techniques directly impacts the accuracy and performance of the instrument.

1. PCB Base Materials

FR-4 High-Tg Laminate – Offers stability, mechanical strength, and low moisture absorption for general precision applications.

High-Frequency Laminates (e.g., Rogers, Taconic) – Provide low dielectric loss and consistent impedance for high-speed and RF measurement circuits.

Polyimide Laminates – Withstand higher temperatures and provide dimensional stability for demanding environments.

Rigid-Flex PCBs – Allow compact, vibration-resistant designs ideal for portable or handheld instruments.

2. Conductive Materials and Finishes

Copper Foil – Standard conductor with controlled thickness (e.g., 1 oz, 2 oz) for optimal current carrying capacity.

Surface Finishes – ENIG (Electroless Nickel Immersion Gold) for corrosion resistance and stable contact; Immersion Silver for cost-effective signal integrity; OSP for environmentally friendly solderability.

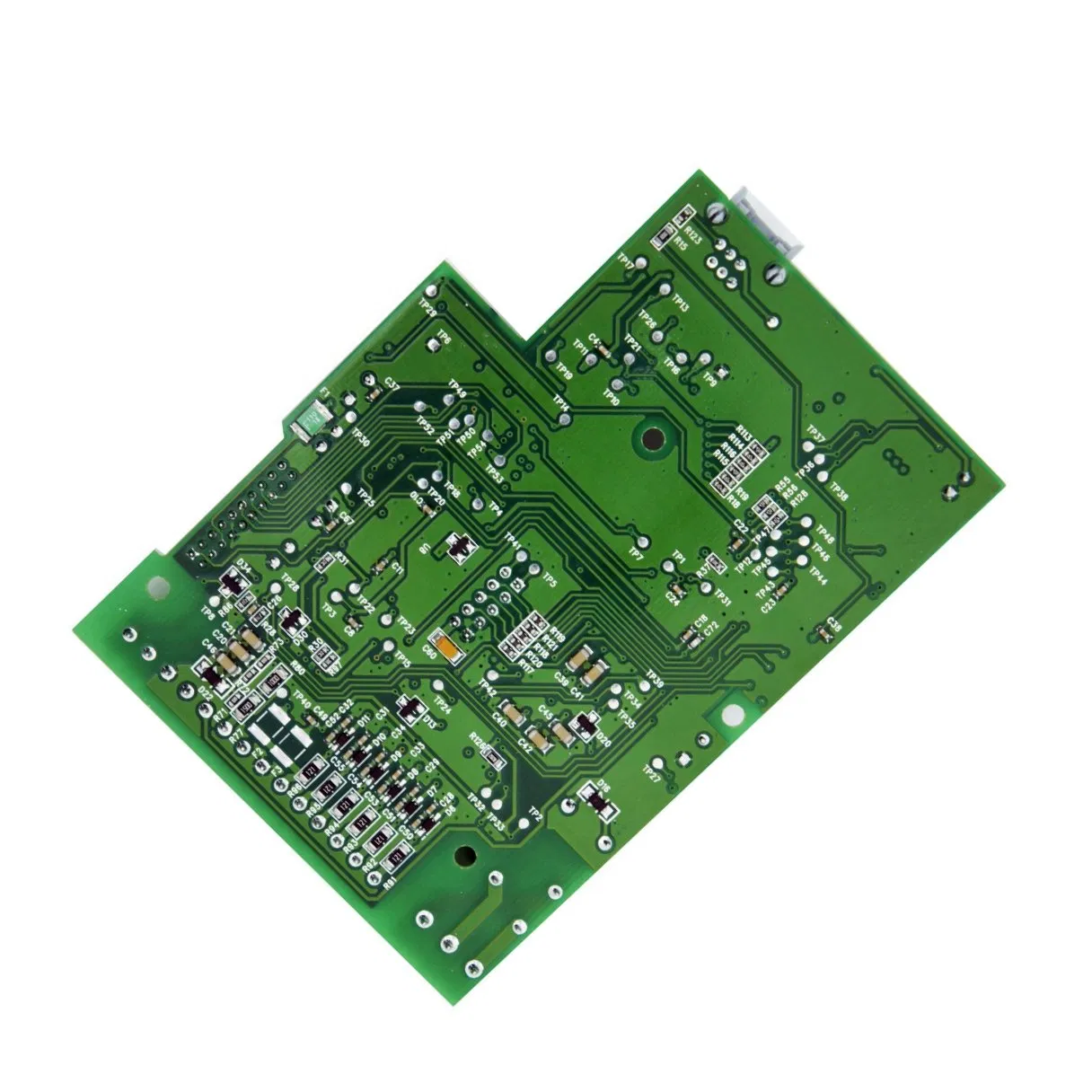

3. Assembly Technologies

Surface Mount Technology (SMT) – Enables compact, high-density placement of precision analog and digital components.

Through-Hole Technology (THT) – Used for connectors, large capacitors, and components requiring high mechanical strength.

Mixed Technology Assembly – Combines SMT and THT for optimal performance and reliability.

4. Signal Integrity and Noise Control Techniques

Controlled impedance trace routing for high-speed or sensitive analog circuits.

Ground planes, shielding, and guard traces to minimize electromagnetic interference (EMI).

Differential signal routing to reduce common-mode noise.

5. Protection and Environmental Resistance

Conformal Coating – Protects against moisture, dust, and contaminants.

Vibration-Resistant Assembly – Reinforced solder joints and adhesive underfills for portable or mobile precision devices.

6. Thermal Management Solutions

Use of thermal vias, copper pours, and small integrated heat sinks for heat-sensitive but thermally active components.

Precision Instruments PCB Assembly Process

The assembly of PCBs for precision instruments demands meticulous attention to detail, strict quality control, and specialized manufacturing techniques to ensure accuracy and reliability in sensitive measurement applications.

1. Design and Prototyping

Develop detailed PCB layouts optimized for low noise, signal integrity, and mechanical stability.

Simulate electrical performance, thermal behavior, and mechanical stress.

Produce prototypes for rigorous testing and validation.

2. Material Selection

Choose appropriate laminates such as high-Tg FR-4, high-frequency materials, or polyimide based on application needs.

Specify copper thickness, surface finishes (ENIG, Immersion Silver), and protective coatings.

3. PCB Fabrication

Use precision imaging and etching to create accurate trace patterns.

Drill and plate vias with tight tolerances for reliable inter-layer connectivity.

Apply surface finishes to protect pads and ensure consistent solderability.

4. Component Procurement and Inspection

Source high-quality, calibrated precision components, microcontrollers, and sensors.

Conduct incoming inspection to verify authenticity and specifications.

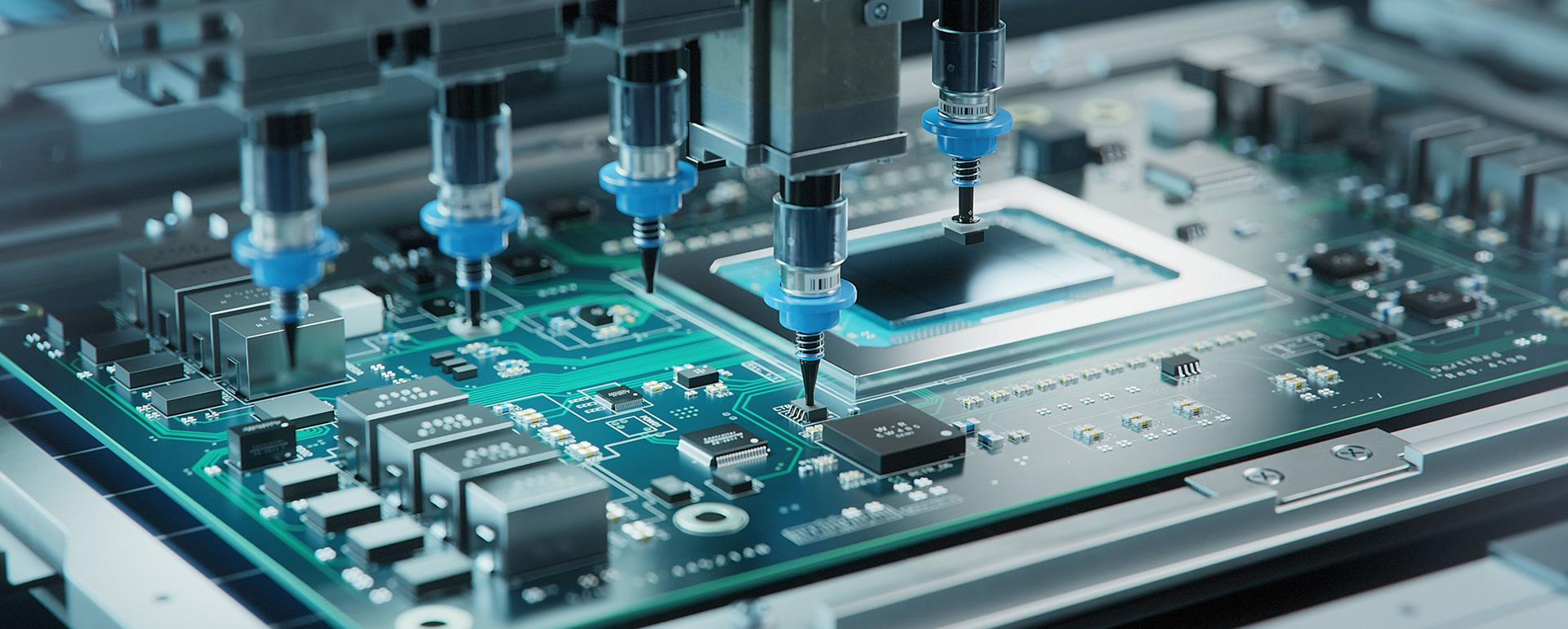

5. Component Placement

Place surface-mount components with high precision using automated pick-and-place machines.

Insert through-hole components where mechanical strength is critical.

6. Soldering

Use reflow soldering for SMT parts, ensuring optimal solder joint quality.

Apply wave or selective soldering for through-hole components.

7. Cleaning and Coating

Thoroughly clean assemblies to remove flux residues and contaminants.

Apply conformal coating to protect against environmental factors like moisture and dust.

8. Testing and Quality Assurance

Perform functional tests to confirm performance and accuracy.

Conduct In-Circuit Testing (ICT) to detect faults such as shorts or opens.

Run environmental stress tests, including vibration and thermal cycling.

9. Final Assembly and Integration

Integrate PCB assemblies into the instrument housing.

Connect sensors, displays, and interfaces.

Perform comprehensive system-level testing before deployment.

Future Implications of Precision Instruments PCB Assembly

As precision instruments evolve with advancements in technology, the role of PCB assembly becomes increasingly critical in enabling higher accuracy, miniaturization, and enhanced functionality. Key future trends and implications include:

1. Miniaturization and Higher Component Density

Continued demand for smaller, more compact PCBs to fit increasingly portable and handheld precision instruments.

Integration of embedded components and multi-layer rigid-flex PCBs to save space without compromising performance.

2. Advanced Materials for Enhanced Performance

Development and adoption of novel laminates with superior thermal, mechanical, and electrical properties to improve signal integrity and durability.

Increased use of high-frequency and low-loss materials for ultra-precise measurements in RF and microwave applications.

3. Integration of Smart and AI-Enabled Components

Incorporation of AI processors and machine learning modules on PCBs to enable real-time data analysis and predictive maintenance.

Enhanced on-board processing reduces latency and dependence on external computing resources.

4. Enhanced Thermal and Environmental Management

Advanced thermal management solutions such as embedded heat pipes and improved coatings to maintain stability under varied operating conditions.

Greater focus on vibration resistance and environmental sealing for instruments used in harsh or mobile environments.

5. Improved Manufacturing and Testing Technologies

Adoption of Industry 4.0 practices including automation, real-time monitoring, and AI-driven quality assurance to reduce defects and improve yield.

Enhanced testing methods to ensure reliability and compliance with stringent industry standards.

6. Sustainable and Eco-Friendly Manufacturing

Increased use of environmentally friendly materials and processes to meet global sustainability goals.

Reduction in hazardous substances and waste through green manufacturing initiatives.

Conclusion

Precision instruments depend heavily on meticulously designed and assembled PCBs to deliver accurate, reliable, and consistent performance. The choice of materials, advanced assembly technologies, and rigorous quality controls ensures that sensitive measurements are not compromised by electrical noise, thermal variations, or mechanical stresses.

Looking ahead, innovations in miniaturization, smart integration, and sustainable manufacturing will further enhance the capabilities and durability of precision instrument PCBs. Manufacturers who prioritize precision engineering and adopt emerging technologies will be well-positioned to meet the evolving demands of this critical industry.

Ready to Elevate Your PCB Projects to New Heights?

In the world of precision instruments, every detail matters — and so does your PCB assembly. Our expertise in advanced materials, precision manufacturing, and rigorous quality assurance ensures your PCBs meet the highest standards of accuracy and reliability.

Partner with us to transform your precision instrument designs into flawless, dependable realities. From initial prototyping to full-scale production, we provide the solutions that help your projects achieve exceptional performance and longevity.