Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

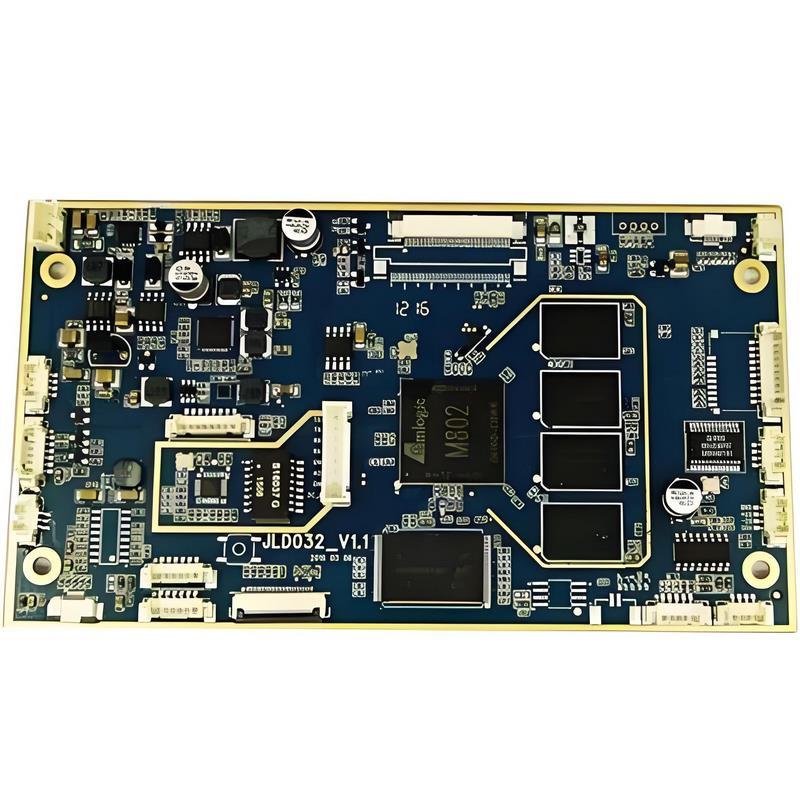

Power Control PCB Assembly

One-stop PCBA/EMS Intelligent Manufacturing Solution

Power Control PCB Assembly

Understanding Power Control PCB Assembly

Power Control PCB Assembly is at the heart of many electronic devices, ensuring they run smoothly and efficiently. It refers to the specialized process of designing and assembling printed circuit boards that manage, regulate, and distribute electrical power within electronic systems. These PCBs are critical in applications that involve high current, high voltage, or power conversion, such as industrial machinery, electric vehicles, power supplies, renewable energy systems, and motor drives.

What Is Power Control?

Power control involves:

Voltage conversion (AC-DC, DC-DC, etc.)

Current regulation and switching

Load distribution

Protection from overcurrent, overvoltage, and overheating

To accomplish these tasks, power control PCBs integrate specialized components and require robust materials and thermal management.

Key Features of Power Control PCB Assemblies

|

Feature |

Description |

|

High Current Traces |

Thick copper layers (2 oz or more) to handle large currents |

|

Thermal Management |

Metal-core PCBs (MCPCB), thermal vias, and heatsinks for heat dissipation |

|

Power Components |

MOSFETs, IGBTs, relays, transformers, power ICs |

|

Isolation and Safety |

Galvanic isolation, optocouplers, high-voltage spacing, conformal coating |

|

Durability |

High-Tg materials, flame-retardant laminates (e.g. FR4-TG170+), and robust solder joints |

|

Protection Circuits |

Fuses, TVS diodes, NTC thermistors, ESD protection devices |

Common Applications

Industrial Power Supplies

AC-DC converters, UPS, inverters

Electric Vehicles (EVs)

Battery management, motor controllers, onboard chargers

Solar and Wind Energy Systems

MPPT controllers, inverters, battery systems

Home Appliances

Power control for HVAC, washing machines, microwaves

LED Lighting Systems

High-efficiency drivers and dimmers

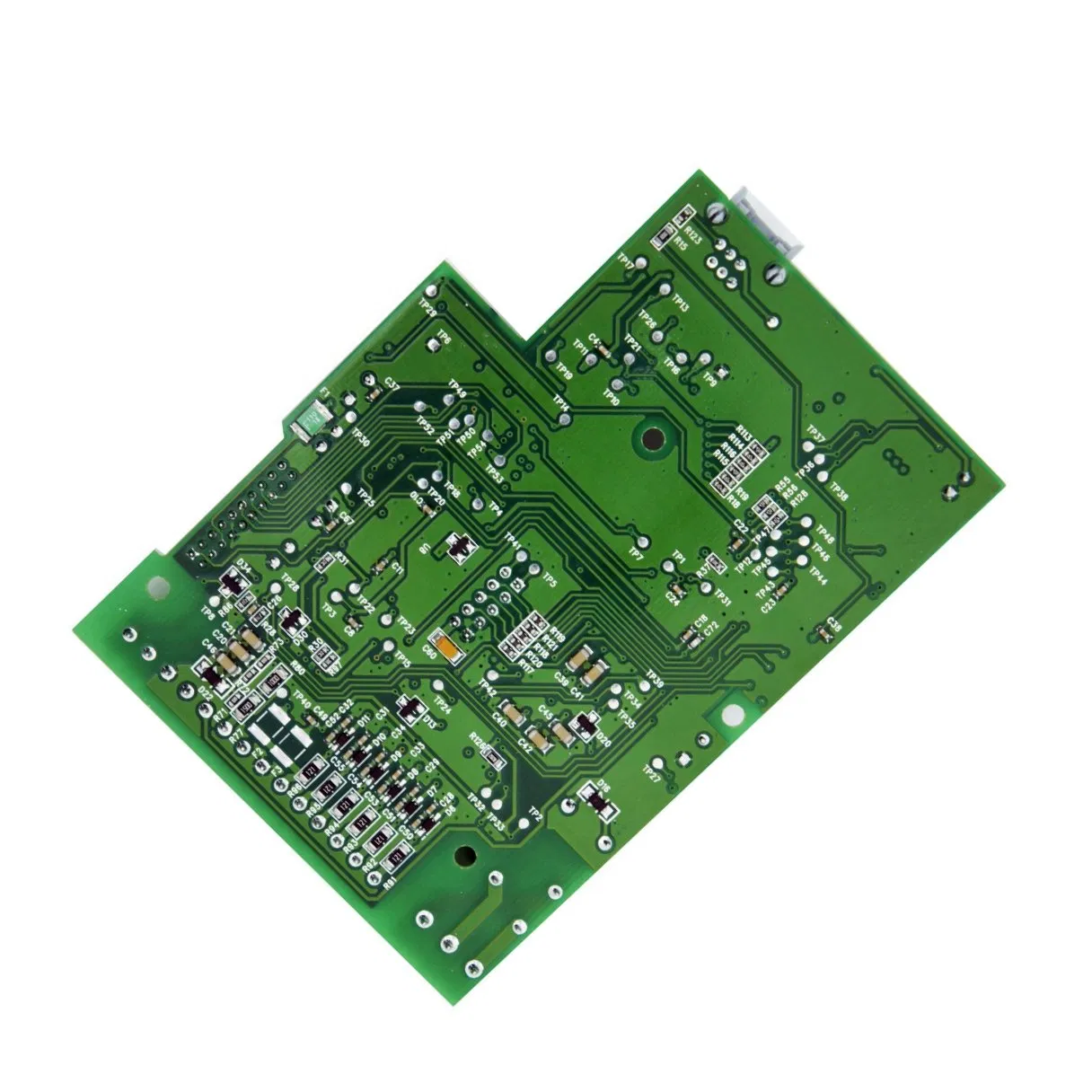

Assembly Considerations

Thick copper handling: Specialized etching and lamination process

Component spacing: Adequate clearance for high-voltage routing

Inspection: X-ray for through-hole power components and BGA packages

Testing: Hi-Pot test, burn-in, functional load testing under real operating conditions

Power Control PCB Assembly is essential for building reliable, safe, and efficient power electronics. It requires expertise in thermal management, high-power component handling, and stringent safety standards. A well-designed power control PCB not only ensures system stability but also extends the lifespan of the entire product.

Applications of Power Control PCB Assembly

Power Control PCB Assemblies are essential in systems that require the conversion, regulation, and distribution of electrical power. These PCBs are designed to handle high current, high voltage, and heat dissipation, making them indispensable across multiple industries.

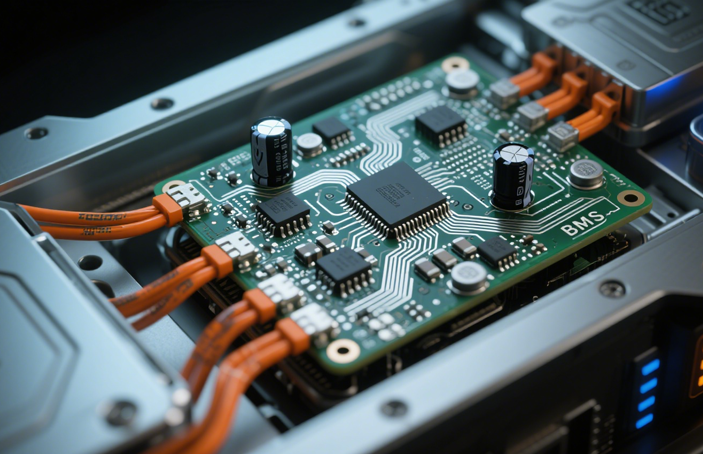

1. Electric Vehicles (EVs) and New Energy Vehicles

Applications:

Battery Management Systems (BMS)

On-board chargers (OBC)

Motor control units (MCU)

DC-DC converters and inverters

Purpose: Efficient power conversion, safe energy storage, and real-time control of traction systems.

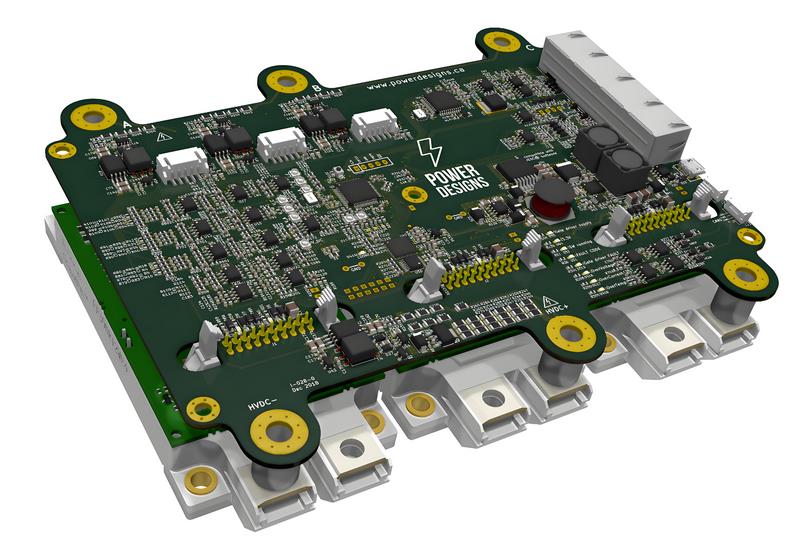

2. Industrial Automation and Motor Control

Applications:

Programmable logic controllers (PLCs)

Servo drives and variable frequency drives (VFDs)

Industrial robots and CNC machines

Purpose: Precise motor control, load regulation, and automation of manufacturing processes.

3. Renewable Energy Systems

Applications:

Solar inverters and charge controllers

Wind turbine power conversion modules

Energy storage and hybrid power systems

Purpose: Converting and managing solar or wind power, ensuring grid compatibility and battery efficiency.

4. Power Supplies and UPS Systems

Applications:

AC-DC and DC-DC switching power supplies

Uninterruptible Power Supplies (UPS)

Power distribution units (PDUs)

Purpose: Provide stable, clean, and uninterrupted power for sensitive electronics and data centers.

5. Smart Home and Appliances

Applications:

HVAC power boards

Smart washing machines, refrigerators, and ovens

Power control for LED lighting systems

Purpose: Efficient energy usage and safe, reliable control in consumer devices.

6. Transportation and Rail Systems

Applications:

Traction control modules

Brake energy recovery systems

Power distribution in electric trains and metros

Purpose: Reliable power control under high-load and harsh conditions.

7. Telecom and Data Centers

Applications:

Power distribution for base stations

Rectifiers and power shelves in server racks

Backup and surge protection systems

Purpose: Continuous, fail-safe power to critical infrastructure.

8. Medical Equipment

Applications:

Power modules in imaging devices (MRI, CT)

Laboratory analyzers and sterilization equipment

Portable and backup medical power systems

Purpose: Stable, isolated power supply for patient safety and precision operation.

Power Control PCB Assemblies are a cornerstone in high-performance electronic systems. From electric vehicles to renewable energy and industrial automation, their role ensures efficient, safe, and reliable power handling in every application scenario.

Power Control PCB Assembly Process

The Power Control PCB Assembly Process encompasses several critical steps, each contributing to the creation of efficient and reliable electronic systems:

1,Design and Layout: Engineers design the PCB, outlining the circuit and component placement, focusing on efficiency, thermal management, and signal integrity. Read more about PCB Design and Basics.

2,Material Selection: Selection of appropriate materials for the PCB substrate and conductive layers to ensure durability under operational stresses. Materials commonly used in power control PCBS include FR-4, high-frequency laminates, and metal-core substrates.

3,Prototype Manufacturing: A prototype PCB is produced and tested to identify and rectify design issues before mass production.

4,Component Sourcing and Preparation: High-quality components compatible with the PCB design are sourced and prepared for assembly.

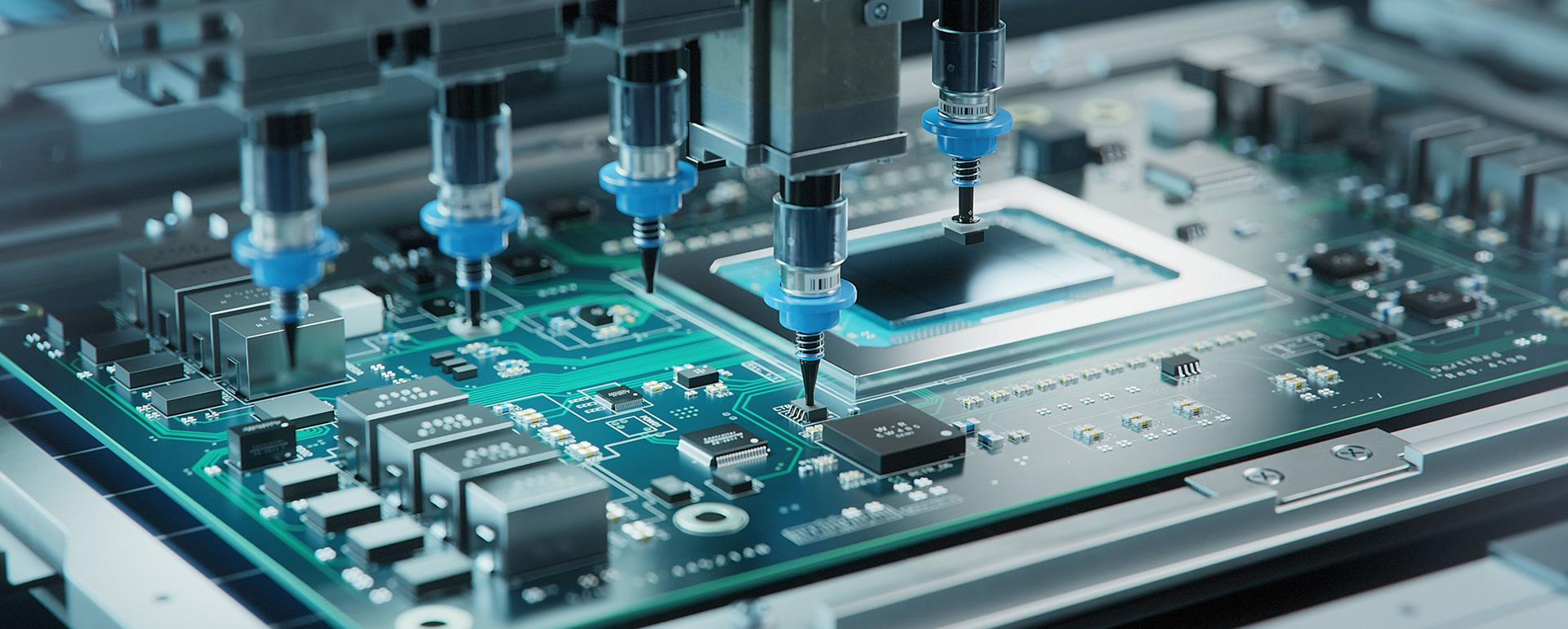

5,PCB Assembly: Components are attached to the PCB using Surface Mount Technology (SMT) for high-density designs or Through-Hole Technology (THT) for enhanced mechanical strength.

6,Inspection and Testing: The assembled PCB is inspected for defects and tested for functionality to ensure it meets all quality and performance standards.

7,Final Assembly: The PCB is integrated into its final assembly, including any necessary mechanical components and external interfaces.

8,Quality Assurance and Delivery: Final quality checks are performed before the power control system is packaged, documented, and shipped to ensure customer satisfaction.

Testing and Quality Assurance

Power control PCBs are deployed in high-stakes environments where failure can lead to system downtime, safety risks, or equipment damage. Therefore, rigorous testing and QA processes are essential to ensure electrical performance, thermal stability, and long-term reliability.

1. Automated Optical Inspection (AOI)

Detects:

Misaligned components

Solder bridging

Missing or reversed parts

Used after SMT assembly to ensure visual and placement accuracy

2. X-ray Inspection

Used for:

BGAs, QFNs, and power packages with hidden solder joints

Verifying voids, solder coverage, and internal lead connections

Critical for detecting failures invisible to AOI

3. In-Circuit Testing (ICT)

Validates:

Component values (resistance, capacitance)

Solder joint connectivity

Basic functional logic

Uses test probes or bed-of-nails fixture for high-speed, automated testing

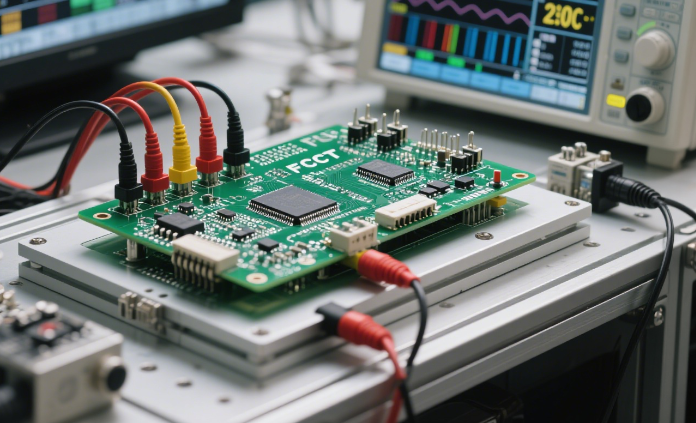

4. Functional Testing (FCT)

Simulates real-world operating conditions

Confirms:

Voltage output regulation

Load switching performance

Short-circuit protection, overvoltage/undervoltage response

Often customized per customer specification or product design

5. Hi-Pot (High Potential) Testing

Applies high voltage across isolated sections (e.g., primary to secondary)

Verifies insulation integrity, isolation distances, and creepage compliance

Essential for power supplies and high-voltage modules

6. Burn-In Test (if applicable)

Runs the board under elevated voltage, current, and temperature for extended periods

Helps identify early-life failures and stress-sensitive components

Common in automotive, aerospace, and industrial power modules

7. Environmental & Reliability Tests (optional based on application):

Thermal cycling: Tests solder joint durability under rapid temperature shifts

Humidity and salt spray: For corrosion resistance

Vibration and shock testing: For rugged or mobile power modules

Conformal coating quality inspection: Ensures environmental protection layers are intact

Final Quality Assurance Checklist Includes:

Visual inspection (manual + machine)

Electrical performance verification

Labeling and traceability (serial numbers, barcodes)

Compliance with industry standards (IPC-A-610, UL, ISO, RoHS)

Testing and QA in Power Control PCB Assembly ensures that the board:

Performs safely under load

Withstands harsh operating conditions

Meets regulatory and customer standards

A strong QA process minimizes field failures and guarantees long-term system reliability in critical power applications.

Benefits of Power Control PCB Assembly

Power Control PCB Assemblies offer numerous advantages that enhance the performance and reliability of electronic devices. Here are some key benefits:

Reliability

Reliability is paramount in any electronic device, and Power Control PCBs excel in this area. By using high-quality materials and rigorous testing processes, these assemblies ensure:

Consistent Performance: Devices operate smoothly without unexpected failures.

Long Lifespan: High reliability translates to a longer operational life for electronic devices.

Safety: Reliable PCBs minimize the risk of electrical failures that could lead to safety hazards.

Efficiency

Power Control PCBs are designed to manage and distribute power efficiently. This efficiency brings several benefits:

Reduced Energy Consumption: Efficient power management means devices use less energy, which is both cost-effective and environmentally friendly.

Optimized Performance: Devices perform better when they receive a stable and appropriate power supply.

Heat Management: Efficient PCBs help manage and dissipate heat, preventing overheating and maintaining performance.

Scalability

Scalability is a significant advantage of Power Control PCBs, allowing them to be used in various applications, from small gadgets to large industrial systems. Benefits include:

Customization: PCBs can be customized to meet the specific needs of different devices and applications.

Versatility: They suit various industries, including consumer electronics, industrial control, and renewable energy.

Future-Proofing: Scalable designs ensure that PCBs can accommodate future technological advancements and increased demands.

Durability

Durability ensures that Power Control PCBs can withstand harsh conditions and prolonged use. This is achieved through:

Robust Materials: Using high-quality, durable materials that can endure extreme conditions.

Protective Coatings: Apply coatings that protect against moisture, dust, and other environmental factors.

Mechanical Stability: Ensuring the PCB can handle physical stresses, such as vibrations and impacts.

Challenges in Power Control PCB Assembly

Designing and assembling Power Control PCBs come with a set of challenges that require innovative solutions:

Heat Management: Power control components generate significant heat. Efficient thermal management solutions are needed to dissipate this heat, preventing damage to the PCB and ensuring long-term reliability.

Space Constraints: As devices become smaller, integrating power control systems without compromising performance or safety becomes increasingly tricky.

Complexity and Cost: The need for high precision and reliability in Power Control PCB Assembly often leads to increased complexity and production costs.

Choosing the Right Power Control PCB Assembly Service

Selecting the right partner for Power Control PCB Assembly is critical, as these boards must meet high-performance, safety, and reliability standards. A qualified assembly service provider should offer technical expertise, process control, and industry compliance to support your project from design to delivery.

1. Experience in Power Electronics

Look for vendors with a proven track record in:

High-voltage and high-current applications

Power supply units (PSU), motor drives, EV systems, industrial controllers

Ask for reference projects or case studies in similar domains

2. Advanced Manufacturing Capabilities

Ensure they can handle:

Thick copper layers (2 oz to 6 oz or more)

Metal-core PCBs (MCPCB) or hybrid stack-ups

Large components, custom heat sinks, and high-power devices

Specialized wave soldering, selective solder, and SMT for heavy components are essential

3. Testing and Quality Assurance Systems

Confirm they offer:

Hi-Pot (high-potential) testing

Functional testing under load

Burn-in and reliability testing

AOI, X-ray inspection, and ICT should be standard

4. Standards and Certifications

Look for compliance with:

ISO 9001 – Quality Management

IPC-A-610 – Acceptability of Electronic Assemblies

UL, CE, RoHS, REACH – depending on your market

Automotive, medical, or industrial certifications as required (e.g. IATF 16949)

5. Design for Manufacturability (DFM) Support

Choose a partner who provides:

Design reviews to optimize trace width, spacing, and thermal layout

Stack-up guidance for high-current and EMI-sensitive designs

Recommendations for cost-efficient material selection and component sourcing

6. Supply Chain & BOM Management

Ensure robust procurement systems for:

Genuine power semiconductors (e.g., MOSFETs, IGBTs)

High-quality transformers, relays, connectors

Alternatives and lifecycle management for long-term product support

7. Customization and Flexibility

Look for assembly services that can handle:

Low to high-volume production runs

Custom packaging, conformal coating, or potting

Rapid prototyping and quick-turn delivery for urgent projects

8. Engineering & After-Sales Support

A reliable partner will offer:

Engineering consultation during the design phase

Clear communication throughout the project

Post-delivery technical assistance and warranty support

| Key Criteria | Why It Matters |

| Power assembly expertise | Ensures safety and performance |

| Thermal & current handling | Supports demanding applications |

| Full testing capabilities | Guarantees product reliability |

| Certifications | Ensures compliance with regulations |

| DFM + engineering support | Speeds up design and lowers costs |

| BOM + supply chain control | Prevents delays and counterfeit parts |

A Strategic Partner, Not Just a Vendor

The right power control PCB assembly service is more than a supplier — they’re a technical partner who helps bring your product to market faster, safer, and smarter.

Future Trends in Power Control PCB Assembly

As the demand for high-efficiency power systems, electrification, and intelligent control continues to rise, Power Control PCB Assembly is evolving rapidly. Emerging technologies, materials, and manufacturing methods are shaping the next generation of power electronics.

1. Higher Power Density Designs

Trend: Reducing board size while increasing power output

Impact:

Tighter layouts with thermal optimization

Integration of advanced cooling structures (e.g. embedded copper blocks, heat pipes)

Emphasis on compact, multilayer MCPCBs and hybrid stack-ups

2. Advanced Thermal Management

Trend: Heat is the biggest limiting factor in power PCB performance

Innovations:

Phase-change materials (PCM) and vapor chambers

Thermally conductive PCB substrates (ceramic, AlN, Si₃N₄)

Embedded thermal vias and active cooling modules

3. Wide Bandgap Semiconductors (SiC and GaN)

Trend: Shift from silicon to SiC (Silicon Carbide) and GaN (Gallium Nitride)

Benefits:

Higher switching frequencies

Better efficiency at high voltages

Requires PCBs with enhanced insulation, reduced parasitics, and lower EMI

4. Smart Power PCBs and Embedded Sensing

Trend: Integration of monitoring and control directly into PCBs

Features:

Embedded temperature, current, and voltage sensors

Real-time data feedback for predictive maintenance

Microcontroller or SoC integration for self-regulating power modules

5. Automated, High-Precision Assembly

Trend: Increased reliance on robotics and Industry 4.0 practices

Examples:

3D AOI and inline X-ray inspection

AI-assisted SMT placement and solder profiling

Digital twins for real-time manufacturing simulation

6. Electrification of Everything (EoE)

Trend: Electrification is extending to transportation, buildings, and industries

Effect:

Surge in demand for high-efficiency power conversion boards

More complex PCBs for EVs, energy storage systems, microgrids

7. Modular & Scalable Power Architectures

Trend: Standardized modular power PCBs for scalable integration

Use Case:

Swappable or stackable power modules

Faster time-to-market for OEMs

Simplified system maintenance and upgrades

8. Green Manufacturing & Sustainability

Trend: Growing focus on environmentally responsible production

Initiatives:

Lead-free, halogen-free materials

Low-carbon footprint PCB fabrication

Recyclable or biodegradable substrate development

| Trend Area | Key Direction |

| Power Density | Compact, multilayer thermal designs |

| Thermal Innovation | Active & passive advanced cooling |

| SiC/GaN Adoption | High-speed, high-voltage capabilities |

| Embedded Intelligence | Built-in sensors and control logic |

| Smart Manufacturing | Robotics, AI, real-time QA |

| Electrification Expansion | EVs, renewables, heavy industry |

| Modular Design | Scalable, pluggable power systems |

| Sustainability | Eco-friendly processes and materials |

The future of Power Control PCB Assembly lies in intelligent integration, material innovation, and digital precision. Businesses that adopt these trends early will lead the way in building safer, more efficient, and smarter power systems for tomorrow’s world.

Conclusion

The future of Power Control PCB Assembly looks promising, with ongoing advancements in materials and technologies. As devices become smaller and smarter, the demand for high-density, efficient, and reliable PCBs will continue to grow.

Integrating PCBs with IoT and other intelligent technologies will drive innovation, leading to more sophisticated and interconnected devices.

Power Control PCB Assemblies are the backbone of many modern electronic devices. For businesses and engineers looking to stay ahead in this competitive field, partnering with experienced and reputable PCB assembly services is crucial.

Ready to Elevate Your PCB Projects to New Heights?

Whether you're building high-performance power systems, intelligent control boards, or next-generation electronics, choosing the right PCB assembly partner is the key to success.

At EdgePCBA, we bring:

Proven expertise in Power Control PCB Assembly

Advanced capabilities in thermal design, high-current handling, and precision manufacturing

Rigorous testing, quality control, and compliance standards

Let us help you turn complex challenges into high-reliability solutions — from prototyping to mass production.

Contact us today to discover how we can empower your next breakthrough.