Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

Choosing the Right Precision Instruments for Optimal PCB Assembly Results

2026-02-13

Choosing the Right Precision Instruments for Optimal PCB Assembly Results

Table of Contents

1. Understanding PCB Assembly: A Brief Overview

2. The Importance of Precision in PCB Assembly

3. Key Precision Instruments for PCB Assembly

3.1 Soldering Equipment

3.2 Testing and Inspection Tools

3.3 Pick and Place Machines

3.4 Reflow Ovens

4. Factors to Consider When Choosing Precision Instruments

4.1 Calibration and Accuracy

4.2 Compatibility with PCB Design

4.3 Budget Constraints

5. Best Practices for Using Precision Instruments in PCB Assembly

6. Common Challenges in PCB Assembly and How to Overcome Them

7. Frequently Asked Questions (FAQs)

8. Conclusion

1. Understanding PCB Assembly: A Brief Overview

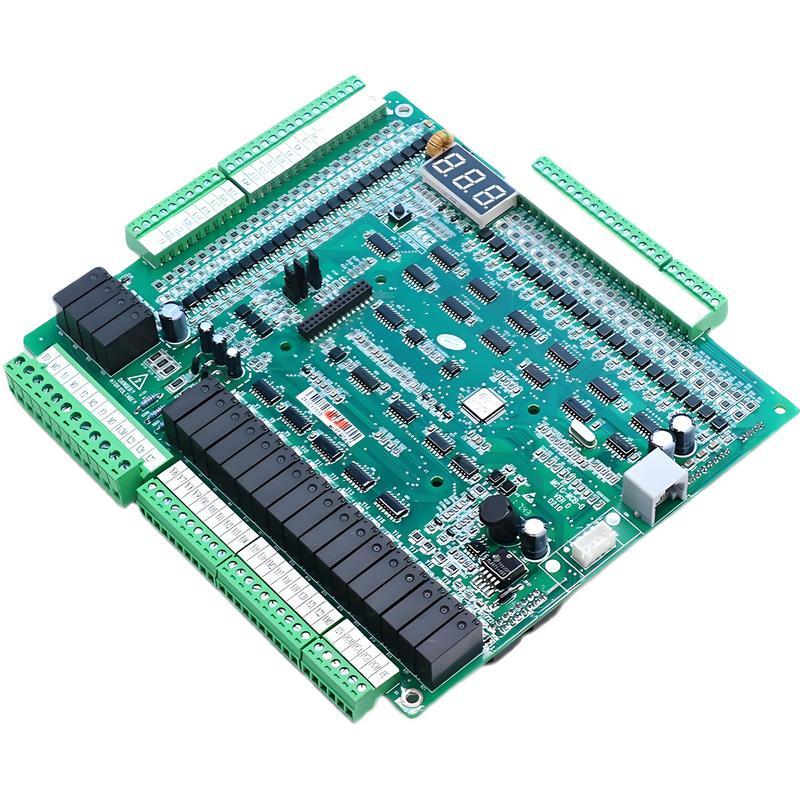

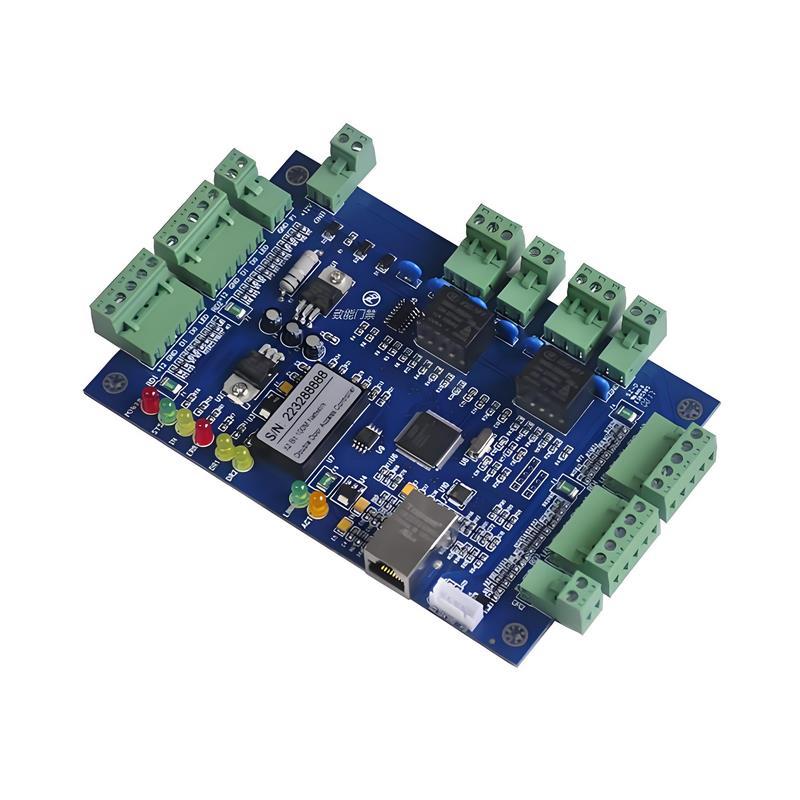

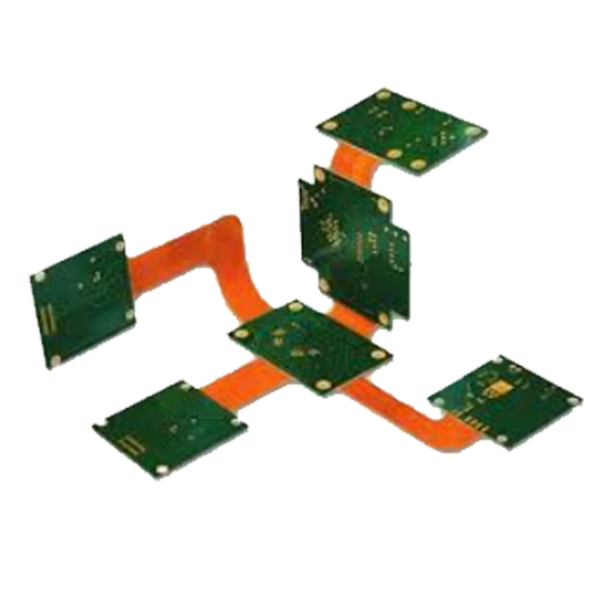

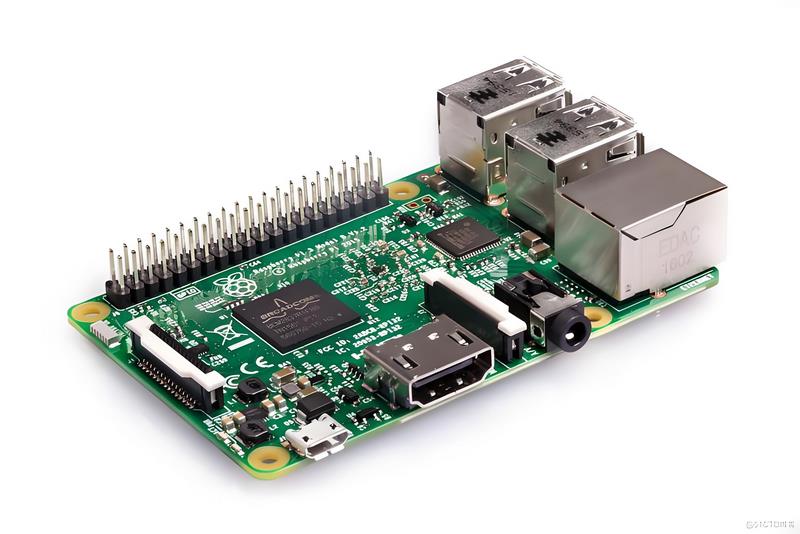

Printed Circuit Board (PCB) assembly is a crucial step in the manufacturing process of electronic devices. It involves the placement of electronic components onto a PCB and the interconnection of these components through soldering. The effectiveness of this process significantly relies on the precision instruments employed, which can greatly influence the quality and reliability of the final product.

2. The Importance of Precision in PCB Assembly

Precision is paramount in PCB assembly for several reasons. Firstly, modern electronic devices are becoming increasingly compact and complex, necessitating a higher degree of accuracy to ensure that components fit correctly and function as intended. Secondly, precision directly impacts the performance and longevity of electronic products. A slight misalignment or poor solder joint can lead to failures, ultimately resulting in costly recalls or repairs.

3. Key Precision Instruments for PCB Assembly

To achieve optimal results in PCB assembly, a variety of precision instruments are essential. Below, we outline several key tools that play a vital role in this process.

3.1 Soldering Equipment

Soldering is fundamental in PCB assembly for connecting electronic components. The right soldering equipment includes soldering irons, soldering stations, and various types of solder. A high-quality soldering iron with adjustable temperature settings offers precision control, ensuring that the heat is applied correctly without damaging sensitive components.

3.2 Testing and Inspection Tools

Testing and inspection are crucial for verifying the integrity of solder joints and ensuring that components are correctly placed. Instruments such as multimeters, oscilloscopes, and automated optical inspection (AOI) systems help detect faults early in the assembly process. Investing in advanced testing tools can significantly reduce the likelihood of defects.

3.3 Pick and Place Machines

Pick and place machines automate the process of placing components onto PCBs, which increases efficiency and precision. These machines utilize vision systems to accurately position components, reducing the risk of human error. When selecting a pick and place machine, consider its speed, accuracy, and compatibility with the types of components you use.

3.4 Reflow Ovens

Reflow ovens are critical for soldering surface-mounted components. They use controlled heat to melt solder paste and create strong electrical connections. Understanding the thermal profiles required for different types of solder is essential for optimizing the reflow process and ensuring reliable joints.

4. Factors to Consider When Choosing Precision Instruments

Selecting the right precision instruments for PCB assembly involves multiple considerations. Here, we highlight the most critical factors to keep in mind.

4.1 Calibration and Accuracy

Calibration is vital to ensure the accuracy of precision instruments. Regularly calibrating your tools helps maintain their performance and guarantees that the measurements taken are reliable. Look for instruments that provide a calibration certificate or are easy to calibrate in-house.

4.2 Compatibility with PCB Design

Before investing in precision instruments, consider their compatibility with your PCB designs. Different designs may require specialized tools for certain components or configurations. Ensuring that your instruments can accommodate your design specifications will prevent issues during assembly.

4.3 Budget Constraints

Budgeting is a significant factor when choosing precision instruments. High-quality tools can be a significant investment, but they often result in long-term savings through increased efficiency and reduced errors. Evaluate your needs and prioritize purchasing the most crucial instruments for your assembly process.

5. Best Practices for Using Precision Instruments in PCB Assembly

Using precision instruments effectively requires knowledge of best practices. Here are some recommended strategies to maximize the potential of your tools.

1. **Regular Training**: Ensure all personnel are trained in using precision instruments properly. Regular training sessions can help staff stay updated on the latest techniques and tools, minimizing errors.

2. **Maintenance**: Implement a routine maintenance schedule for your instruments. Regular checks and servicing can prolong the lifespan of your tools and ensure they perform optimally.

3. **Documentation**: Keep accurate records of calibration and maintenance activities. This documentation can help track performance issues and provide insight into when instruments may need replacement.

6. Common Challenges in PCB Assembly and How to Overcome Them

Despite the best efforts to ensure precision, several challenges can arise during PCB assembly. Below are some common issues and strategies to address them.

1. **Component Misplacement**: This can lead to significant assembly errors. Utilizing advanced pick and place machines with high-resolution cameras can help mitigate this issue.

2. **Solder Defects**: Issues such as bridging and insufficient solder can compromise connections. Employing proper soldering techniques, along with quality control measures such as AOI systems, can help identify and rectify these problems early.

3. **Thermal Issues**: Inadequate thermal profiles in reflow soldering can lead to defects. Regularly reviewing and adjusting thermal profiles based on the components used can significantly enhance solder quality.

7. Frequently Asked Questions (FAQs)

What are the essential tools required for PCB assembly?

The essential tools for PCB assembly include soldering equipment, testing and inspection tools, pick and place machines, and reflow ovens.

How can I improve the precision of my PCB assembly?

Improving precision involves regular calibration of instruments, using high-quality tools, and adhering to best practices during the assembly process.

What common challenges arise during PCB assembly?

Common challenges include component misplacement, solder defects, and thermal issues during reflow soldering.

How often should I calibrate my precision instruments?

Calibration frequency depends on usage but should be done at least once every six months or more frequently if instruments are used extensively.

What factors should I consider when selecting a pick and place machine?

Key factors include speed, accuracy, component compatibility, and ease of operation.

8. Conclusion

In conclusion, the selection of precision instruments is critical for achieving optimal results in PCB assembly. By understanding the importance of precision, familiarizing yourself with essential tools, and considering factors such as calibration, compatibility, and budget, you can significantly enhance the efficiency and quality of your PCB production process. Implementing best practices and addressing common challenges will further solidify your success in this intricate field. By investing in the right precision instruments and continually improving your assembly techniques, you can ensure the reliability and performance of your electronic devices, paving the way for innovation and excellence in your projects.

Related news