Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

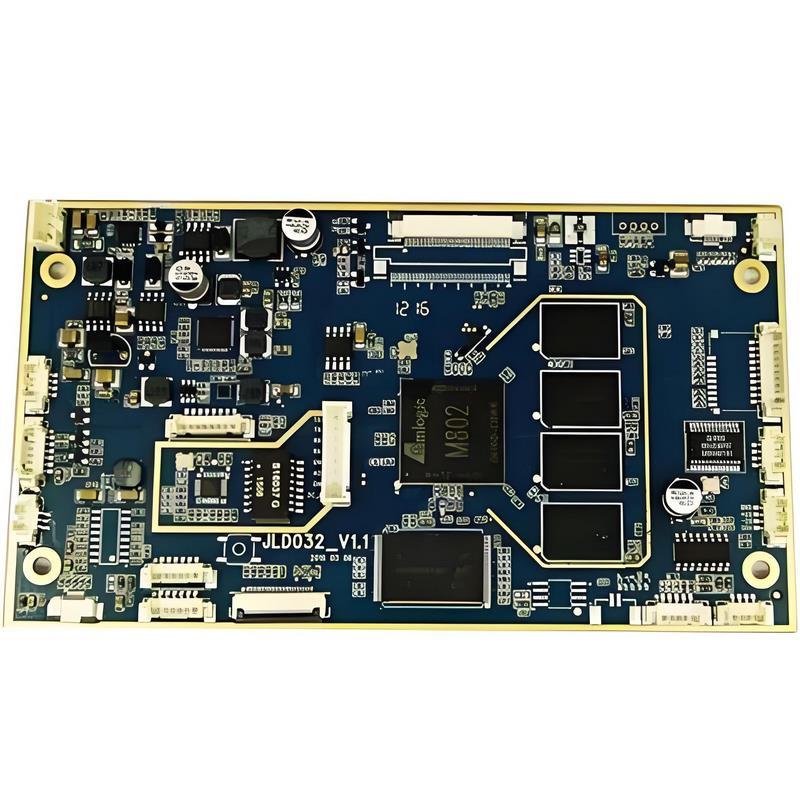

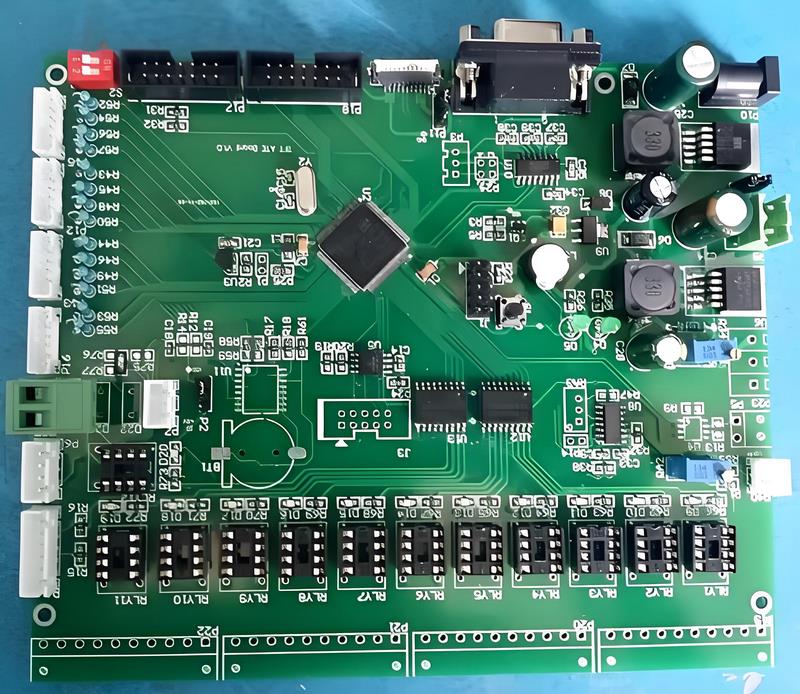

Automation equipment PCB Assembly

One-stop PCBA/EMS Intelligent Manufacturing Solution

Automation equipment PCB Assembly

The Role of PCBs in Automation equipment

In automation systems, PCBs facilitate communication between sensors, controllers, actuators, and user interfaces, enabling precise control and monitoring of industrial processes.

Automation equipment relies on PCBs to support high-speed data processing, real-time feedback loops, and robust power management. These PCBs are engineered to withstand harsh industrial environments, including exposure to vibrations, temperature fluctuations, and electrical noise.

By providing a compact, reliable platform for complex circuitry, PCBs enable automation equipment to achieve higher efficiency, accuracy, and safety—driving advancements in manufacturing, robotics, and process control industries.

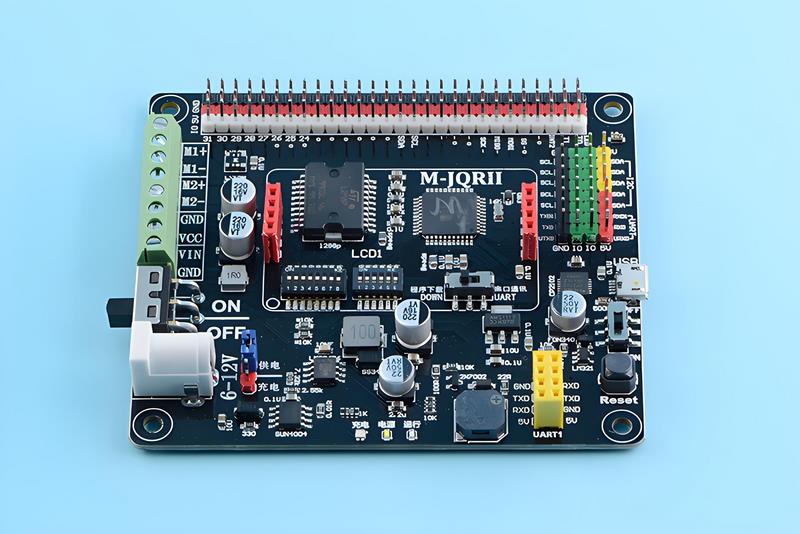

Key Components of Automation equipment PCB Assembly

Automation equipment PCBs integrate a variety of specialized components to enable precise control, data acquisition, and communication within industrial systems. Key components include:

1. Microcontrollers and Programmable Logic Controllers (PLCs)

Serve as the central processing units that execute automation logic and manage system operations.

2. Sensors and Signal Conditioning Circuits

Interface with various sensors (temperature, pressure, proximity, etc.) to acquire real-time data and convert it into usable signals.

3. Power Management Modules

Voltage regulators, DC-DC converters, and power protection circuits ensure stable and reliable power delivery to all components.

4. Communication Interfaces

Support industrial protocols such as Ethernet/IP, Modbus, CAN bus, or PROFIBUS for seamless integration with control networks.

5. Actuator Drivers

Control motors, valves, relays, and other actuators to perform mechanical actions based on processed inputs.

6. Memory Modules

Store firmware, configuration data, and process logs for system functionality and diagnostics.

7. User Interface Components

Include displays, buttons, LEDs, and touchscreens for operator interaction and system monitoring.

8. Protection Components

Fuses, ESD protection, and transient voltage suppressors safeguard sensitive electronics from electrical faults and surges.

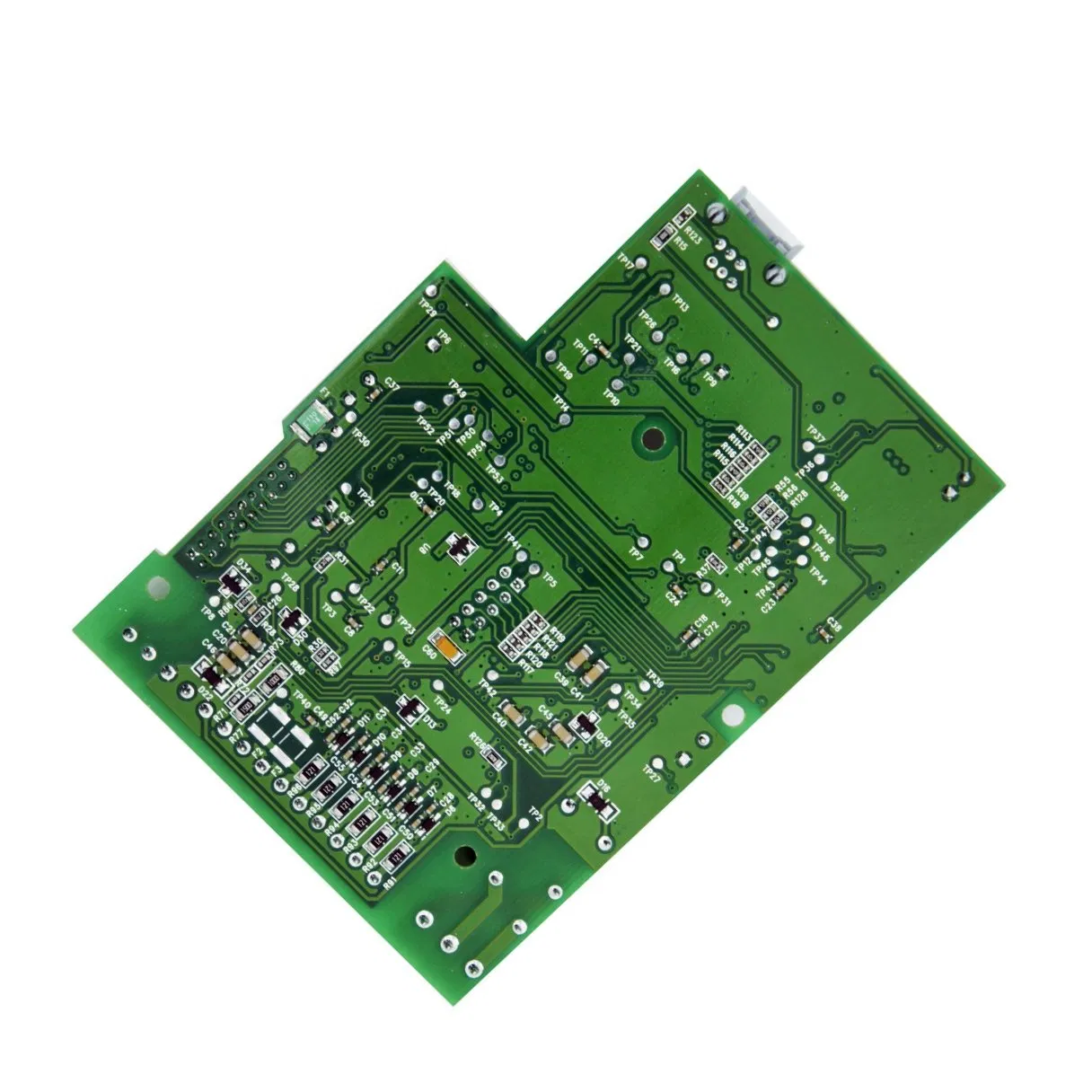

Materials and Technologies for Automation equipment PCB Assembly

PCBs used in automation equipment must meet rigorous standards for durability, reliability, and performance, as they often operate in demanding industrial environments. The choice of materials and technologies is crucial to ensuring these requirements are met.

1. PCB Substrate Materials

High-Tg FR-4 – Offers enhanced thermal stability and mechanical strength for circuits exposed to heat and vibration.

Polyimide and Flexible Substrates – Used in applications requiring bending or space-saving designs.

Metal Core PCBs (MCPCBs) – Employed in high-power applications where heat dissipation is critical.

2. Copper Thickness and Layer Count

Heavy Copper (2 oz or higher) – Supports high current loads typical in motor drives and power circuits.

Multilayer Boards – Enable complex routing, signal integrity, and electromagnetic compatibility (EMC) management.

3. Surface Finishes

ENIG (Electroless Nickel Immersion Gold) – Provides excellent solderability, corrosion resistance, and is ideal for fine-pitch components.

HASL (Hot Air Solder Leveling) – Cost-effective option for general-purpose boards.

OSP (Organic Solderability Preservatives) – Environmentally friendly and suitable for lead-free assembly.

4. Assembly Technologies

Surface Mount Technology (SMT) – Allows for high-density component placement and miniaturization.

Through-Hole Technology (THT) – Used for connectors and components requiring mechanical robustness.

Automated Optical Inspection (AOI) – Ensures assembly quality by detecting defects early.

5. Thermal Management

Thermal Vias and Copper Pours – Improve heat dissipation for power components.

Heat Sinks and Thermal Pads – Applied to components generating significant heat.

6. EMI/EMC Control

Ground Planes and Shielding Layers – Mitigate electromagnetic interference in sensitive circuits.

Ferrite Beads and Filters – Suppress noise on power and signal lines.

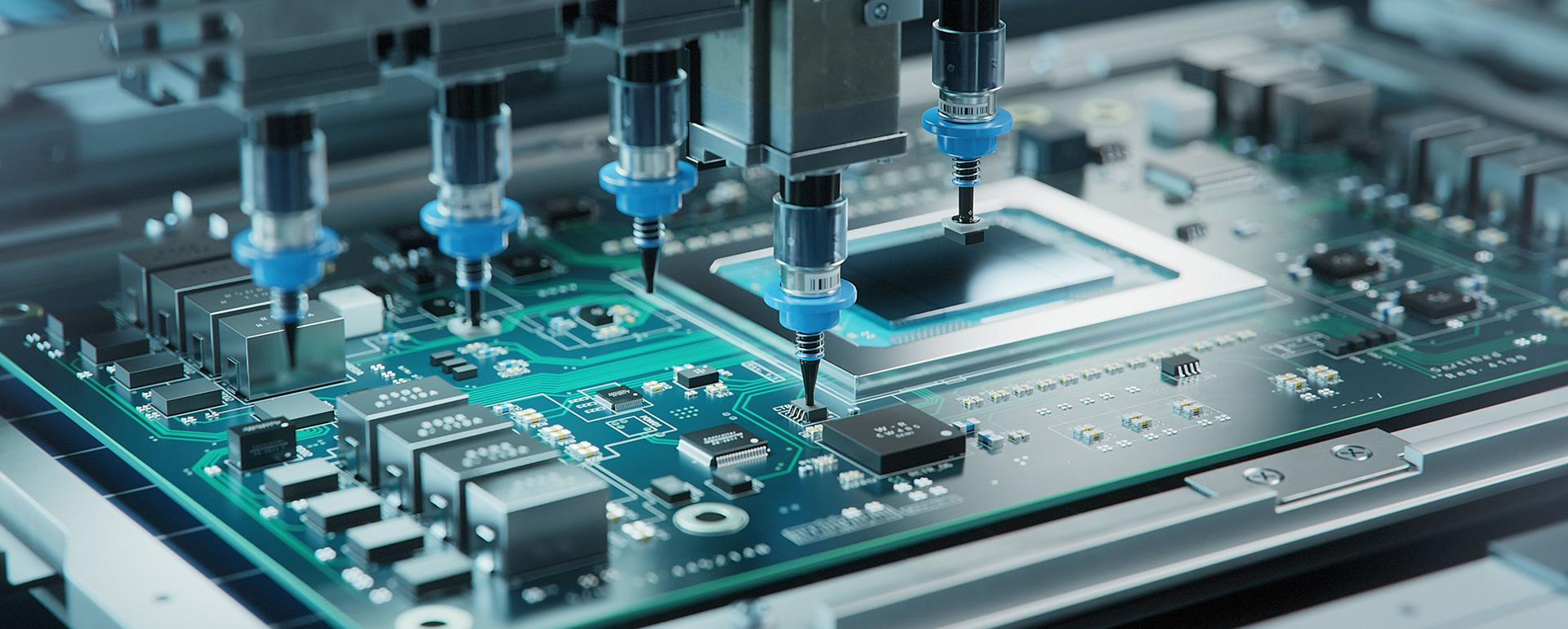

Automation equipment PCB Assembly Process

The assembly of PCBs for automation equipment requires precision, durability, and stringent quality controls to ensure reliable operation in industrial environments. The key steps include:

1. Design and Prototyping

Develop PCB layouts that support complex control logic, sensor integration, and industrial communication protocols.

Prototype fabrication and testing to validate performance and compliance with industrial standards.

2. Material Preparation

Selection of high-Tg substrates and heavy copper layers tailored for heat and power demands.

Cleaning and surface preparation of PCB panels for optimal soldering.

3. Component Procurement and Inspection

Sourcing components from certified suppliers to ensure quality and authenticity.

Incoming inspection to detect defects or counterfeit parts.

4. Component Placement

Automated pick-and-place for SMT components such as microcontrollers, sensors, and communication ICs.

Manual or semi-automated insertion of through-hole components like connectors and power devices.

5. Soldering

Reflow soldering for SMT parts with carefully controlled thermal profiles.

Wave or selective soldering for through-hole components, ensuring solid electrical and mechanical connections.

6. Cleaning and Inspection

Post-solder cleaning to remove flux residues and contaminants.

Automated Optical Inspection (AOI) and X-ray inspection for quality assurance.

7. Testing

In-Circuit Testing (ICT) to verify electrical connections and component functionality.

Functional Testing to simulate real-world operation and validate system performance.

8. Final Assembly and Packaging

Integration of PCBs into automation equipment housings.

Protective packaging to prevent damage during shipping and handling.

Future Implications of Automation equipment PCB Assembly

The future of automation equipment PCB assembly is poised for significant advancements driven by technological innovation and evolving industrial demands. Key trends shaping this future include:

1. Increased Integration of AI and Machine Learning

PCBs will support more powerful AI processors and neural network accelerators to enable smarter, self-optimizing automation systems.

Real-time data processing and predictive analytics will become standard features.

2. Miniaturization and Higher Density Designs

Continued push towards compact PCBs with higher component density will allow more functionality within smaller footprints.

Flexible and rigid-flex PCBs will enable innovative form factors and improved integration in constrained spaces.

3. Enhanced Connectivity and IoT Integration

Integration of advanced communication modules (5G, Wi-Fi 6, Bluetooth Low Energy) will facilitate seamless IoT connectivity.

This will enable remote monitoring, diagnostics, and cloud-based control of automation systems.

4. Improved Reliability and Durability

Use of advanced materials and coatings to enhance resistance to harsh industrial environments (temperature, moisture, vibration).

Adoption of more rigorous testing and quality assurance practices leveraging AI-driven inspection.

5. Sustainability and Eco-Friendly Manufacturing

Increasing emphasis on using lead-free materials, recyclable substrates, and energy-efficient manufacturing processes.

Greater focus on reducing waste and environmental impact throughout the PCB lifecycle.

Conclusion

Through the use of advanced materials, precise assembly processes, and cutting-edge technologies, PCBs in automation systems meet the rigorous demands of industrial environments.

Looking forward, innovations in AI integration, miniaturization, connectivity, and sustainability will shape the future of automation PCB assembly, empowering smarter and more adaptable industrial solutions. Embracing these trends will position manufacturers and designers at the forefront of the evolving automation landscape.

Ready to Elevate Your PCB Projects to New Heights?

In the rapidly evolving world of industrial automation, precision, reliability, and innovation are key. Our expert PCB assembly services combine advanced materials, meticulous quality control, and cutting-edge manufacturing technologies to deliver robust solutions that power your automation equipment.

Partner with us to bring your automation projects to life with PCBs engineered for performance, durability, and future-ready adaptability.