Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

Understanding Elevator Control PCB Assembly: Key Insights for the Electronics Industry

2026-02-10

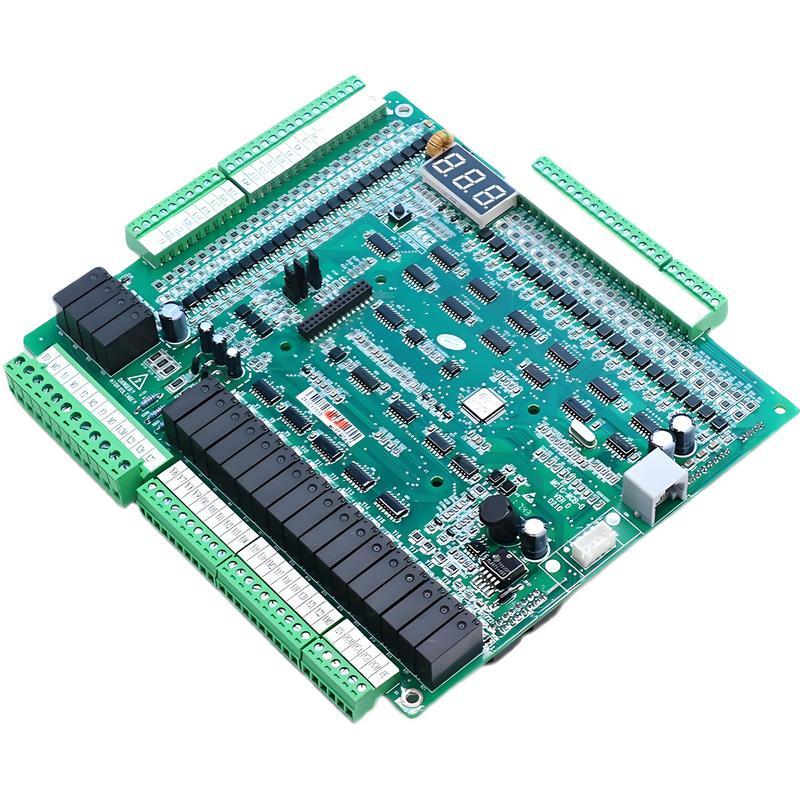

Elevator Control PCB Assembly plays a crucial role in the operation of elevator systems. The printed circuit board (PCB) acts as the backbone for various electronic components, enabling effective communication and control for safe and efficient elevator operation. Understanding the essential elements of this assembly is beneficial for anyone involved in the electronics industry, especially those focusing on other electronic components.

One of the primary considerations in Elevator Control PCB Assembly is the design process. It typically begins with circuit design, which requires a thorough understanding of the elevator's operational requirements. Engineers and designers must ensure that the PCB can accommodate the necessary sensors, motors, and control units that facilitate smooth elevator movements. This involves selecting appropriate materials and components that can withstand the operational conditions such as temperature fluctuations and vibrations.

Moreover, attention to detail during the assembly process is critical. Proper soldering techniques, quality control checks, and thorough testing protocols must be implemented to ensure reliability and performance. An effective assembly process will mitigate the risk of faults that could lead to elevator malfunctions, which are not only inconvenient but can also pose safety risks to users.

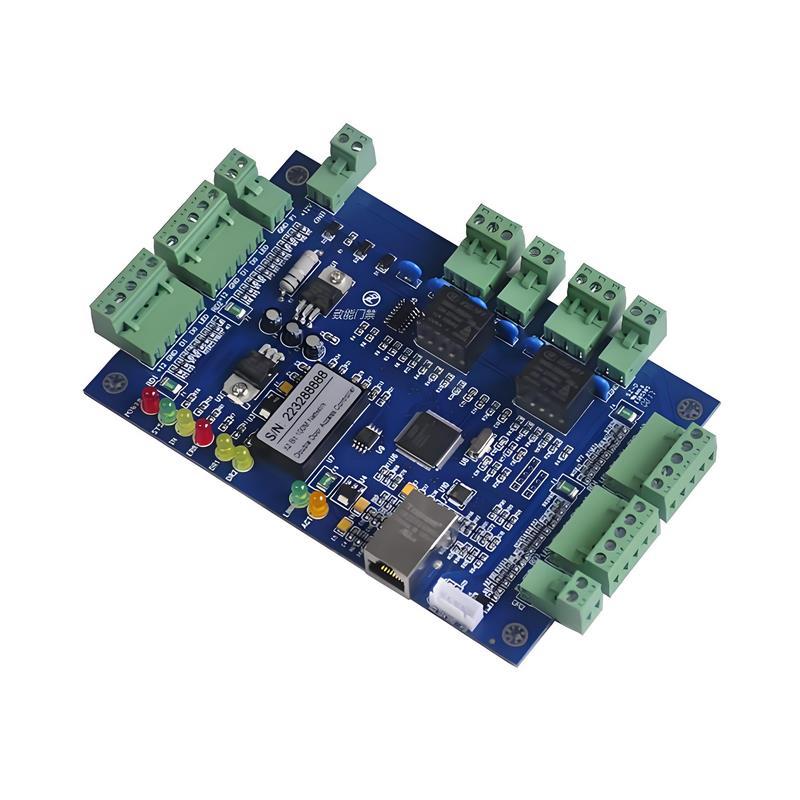

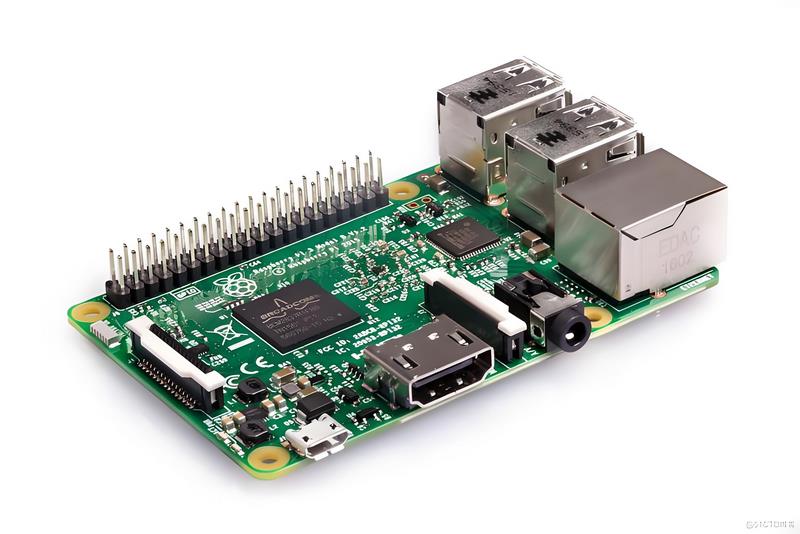

Another vital aspect is the integration of advanced technology into Elevator Control PCB Assembly. Innovations such as IoT (Internet of Things) capabilities can enhance elevator systems by allowing for remote monitoring and predictive maintenance. This evolution in technology demands that manufacturers stay updated with current trends and incorporate flexible designs that can accommodate potential future upgrades.

Furthermore, compliance with international safety and quality standards is imperative. Adhering to regulatory requirements not only ensures the safety of the elevator systems but also builds trust with end-users and stakeholders. It is essential for companies to stay informed about the latest regulations and incorporate them into their PCB assembly processes.

In conclusion, a comprehensive understanding of Elevator Control PCB Assembly is vital for professionals in the electronics industry. By focusing on design, assembly quality, technological integration, and regulatory compliance, businesses can improve their elevator systems' reliability and efficiency. This knowledge not only enhances product offerings but also positions companies favorably in a competitive market. As technology continues to advance, staying informed and adaptable will be key to long-term success in this field.

One of the primary considerations in Elevator Control PCB Assembly is the design process. It typically begins with circuit design, which requires a thorough understanding of the elevator's operational requirements. Engineers and designers must ensure that the PCB can accommodate the necessary sensors, motors, and control units that facilitate smooth elevator movements. This involves selecting appropriate materials and components that can withstand the operational conditions such as temperature fluctuations and vibrations.

Moreover, attention to detail during the assembly process is critical. Proper soldering techniques, quality control checks, and thorough testing protocols must be implemented to ensure reliability and performance. An effective assembly process will mitigate the risk of faults that could lead to elevator malfunctions, which are not only inconvenient but can also pose safety risks to users.

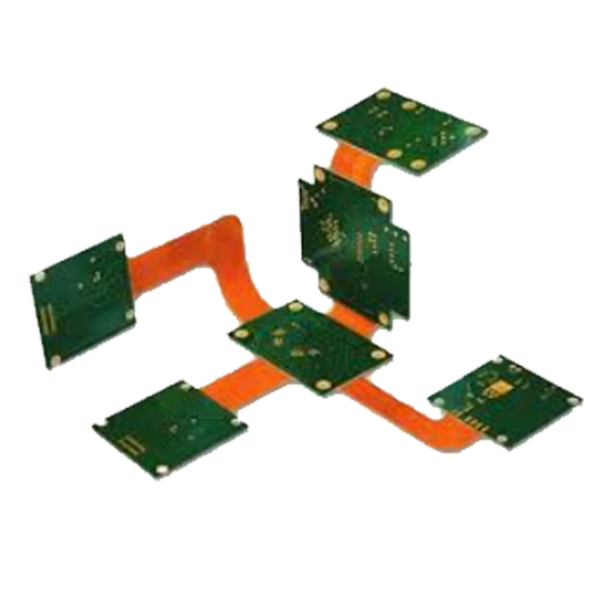

Another vital aspect is the integration of advanced technology into Elevator Control PCB Assembly. Innovations such as IoT (Internet of Things) capabilities can enhance elevator systems by allowing for remote monitoring and predictive maintenance. This evolution in technology demands that manufacturers stay updated with current trends and incorporate flexible designs that can accommodate potential future upgrades.

Furthermore, compliance with international safety and quality standards is imperative. Adhering to regulatory requirements not only ensures the safety of the elevator systems but also builds trust with end-users and stakeholders. It is essential for companies to stay informed about the latest regulations and incorporate them into their PCB assembly processes.

In conclusion, a comprehensive understanding of Elevator Control PCB Assembly is vital for professionals in the electronics industry. By focusing on design, assembly quality, technological integration, and regulatory compliance, businesses can improve their elevator systems' reliability and efficiency. This knowledge not only enhances product offerings but also positions companies favorably in a competitive market. As technology continues to advance, staying informed and adaptable will be key to long-term success in this field.

Related news