Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

Understanding UAV PCB Assembly: Key Aspects and Considerations

2026-02-04

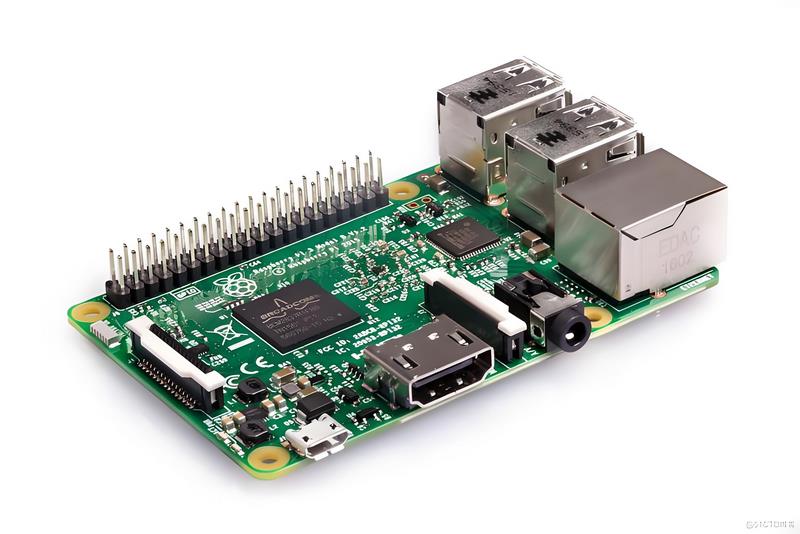

UAV PCB assembly is a critical process in the development of Unmanned Aerial Vehicles, which are increasingly utilized in various applications such as surveillance, agriculture, delivery services, and more. The assembly of printed circuit boards (PCBs) tailored for UAVs requires a thorough understanding of both the electronic and mechanical demands of these advanced systems.

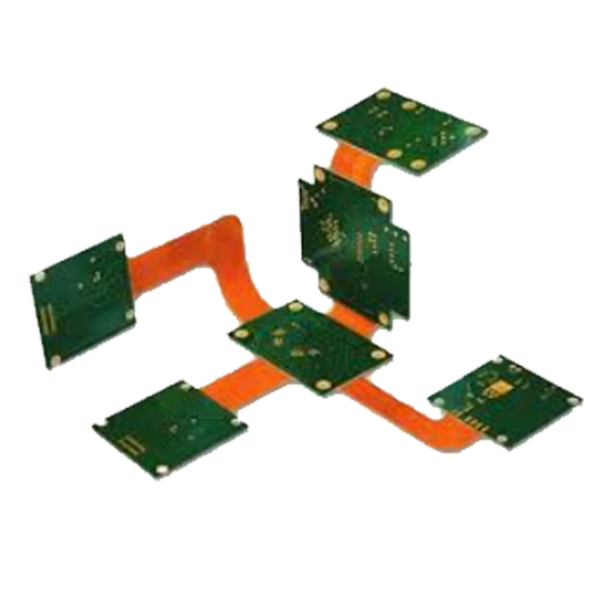

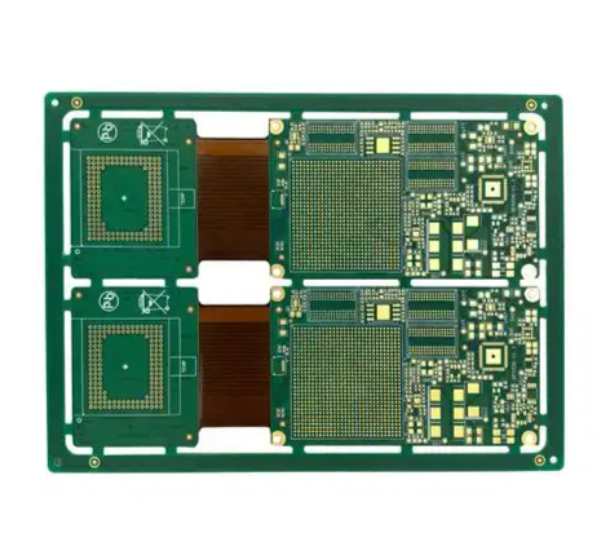

The first key aspect of UAV PCB assembly is the importance of design. Engineers must consider the specific functions the UAV will perform, as this dictates the types of components required. For instance, high-frequency RF components might be necessary for communication systems, while specialized sensors can be integrated for navigation and obstacle avoidance. The PCB layout must also be optimized to ensure minimal size and weight, as UAVs often have strict weight limits that affect their performance and battery life.

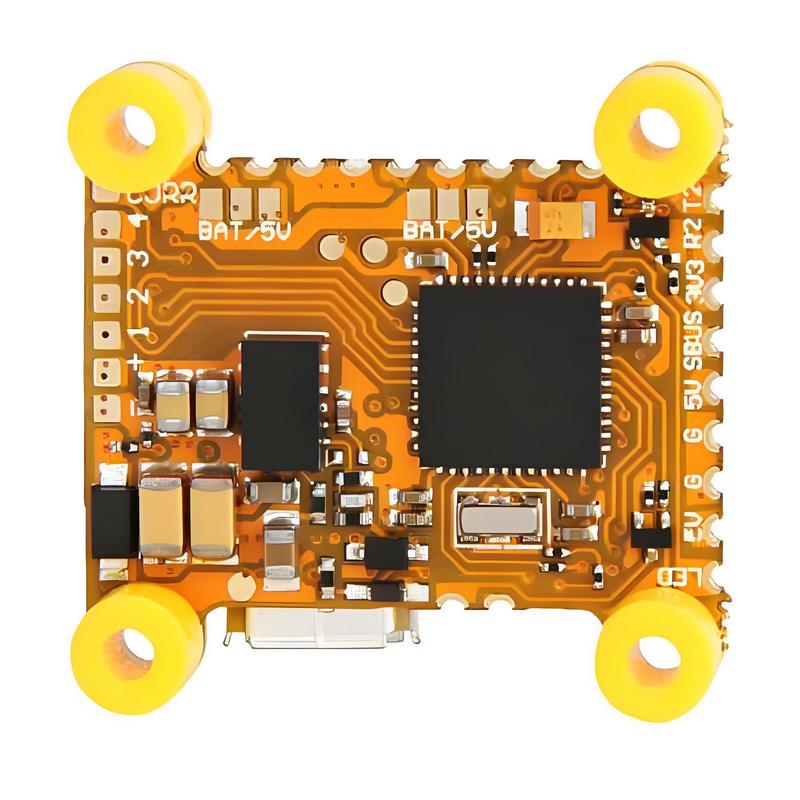

Another critical consideration is the selection of materials. The performance of UAVs can be significantly influenced by the materials used in the PCB assembly. High-quality substrates with excellent thermal and electrical properties are essential to withstand the operational conditions UAVs face. Furthermore, choosing components that are lightweight yet durable can greatly enhance the overall effectiveness of the UAV.

The assembly process itself involves several steps, including soldering, component placement, and testing. Automated processes such as Surface Mount Technology (SMT) are often employed to ensure precision and repeatability in the assembly of PCBs. This approach not only speeds up production but also minimizes human error, which is crucial when dealing with the sophisticated technologies found in UAVs.

Quality control is another vital element in UAV PCB assembly. Each board must undergo rigorous testing to ensure reliability and functionality. This includes checking for solder integrity, component placement accuracy, and overall electrical performance. Given the critical nature of UAV operations, any failure could lead to significant issues, making thorough testing an indispensable part of the assembly process.

Lastly, regulatory compliance plays a significant role in the UAV industry. PCB assemblies must adhere to various industry standards and regulations to ensure safety and reliability. Manufacturers should stay informed about the latest guidelines to avoid potential legal and operational challenges.

In summary, UAV PCB assembly is a complex but essential process that requires careful consideration of design, materials, assembly techniques, quality control, and regulatory compliance. Understanding these aspects can help professionals in the electronic components industry develop more effective UAVs, thereby enhancing the capabilities and applications of these innovative aerial vehicles.

The first key aspect of UAV PCB assembly is the importance of design. Engineers must consider the specific functions the UAV will perform, as this dictates the types of components required. For instance, high-frequency RF components might be necessary for communication systems, while specialized sensors can be integrated for navigation and obstacle avoidance. The PCB layout must also be optimized to ensure minimal size and weight, as UAVs often have strict weight limits that affect their performance and battery life.

Another critical consideration is the selection of materials. The performance of UAVs can be significantly influenced by the materials used in the PCB assembly. High-quality substrates with excellent thermal and electrical properties are essential to withstand the operational conditions UAVs face. Furthermore, choosing components that are lightweight yet durable can greatly enhance the overall effectiveness of the UAV.

The assembly process itself involves several steps, including soldering, component placement, and testing. Automated processes such as Surface Mount Technology (SMT) are often employed to ensure precision and repeatability in the assembly of PCBs. This approach not only speeds up production but also minimizes human error, which is crucial when dealing with the sophisticated technologies found in UAVs.

Quality control is another vital element in UAV PCB assembly. Each board must undergo rigorous testing to ensure reliability and functionality. This includes checking for solder integrity, component placement accuracy, and overall electrical performance. Given the critical nature of UAV operations, any failure could lead to significant issues, making thorough testing an indispensable part of the assembly process.

Lastly, regulatory compliance plays a significant role in the UAV industry. PCB assemblies must adhere to various industry standards and regulations to ensure safety and reliability. Manufacturers should stay informed about the latest guidelines to avoid potential legal and operational challenges.

In summary, UAV PCB assembly is a complex but essential process that requires careful consideration of design, materials, assembly techniques, quality control, and regulatory compliance. Understanding these aspects can help professionals in the electronic components industry develop more effective UAVs, thereby enhancing the capabilities and applications of these innovative aerial vehicles.

Related news