Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

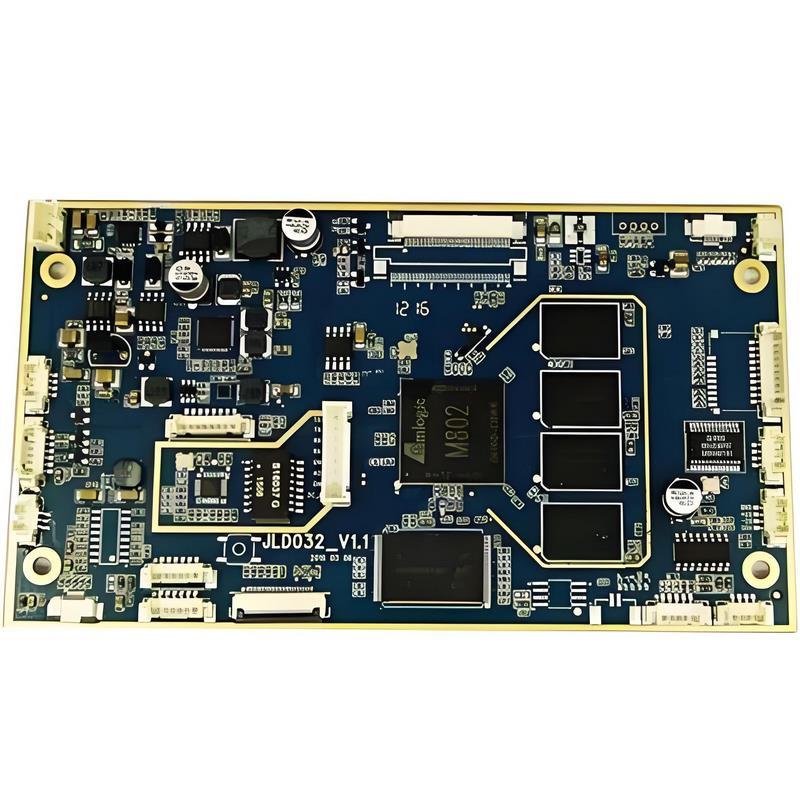

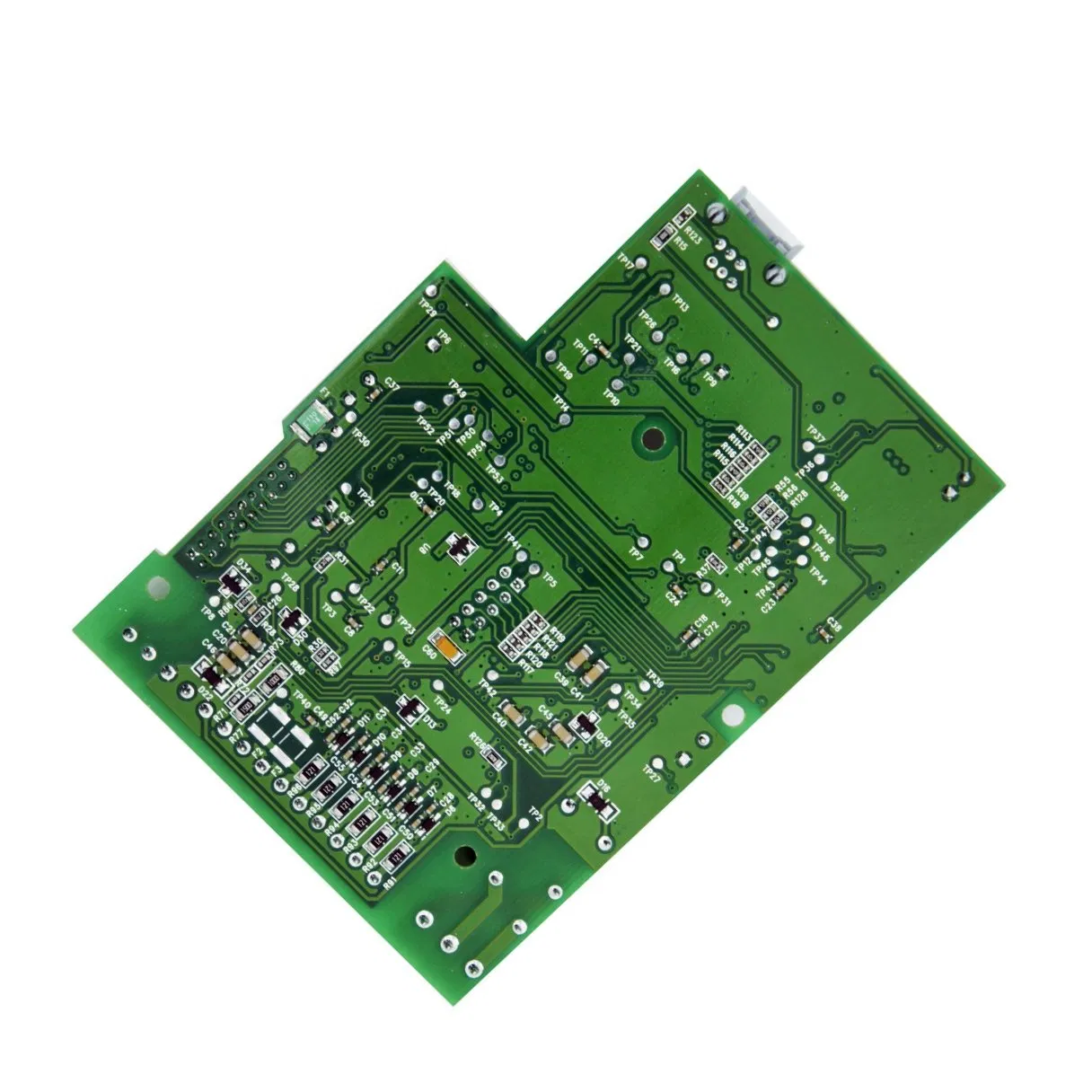

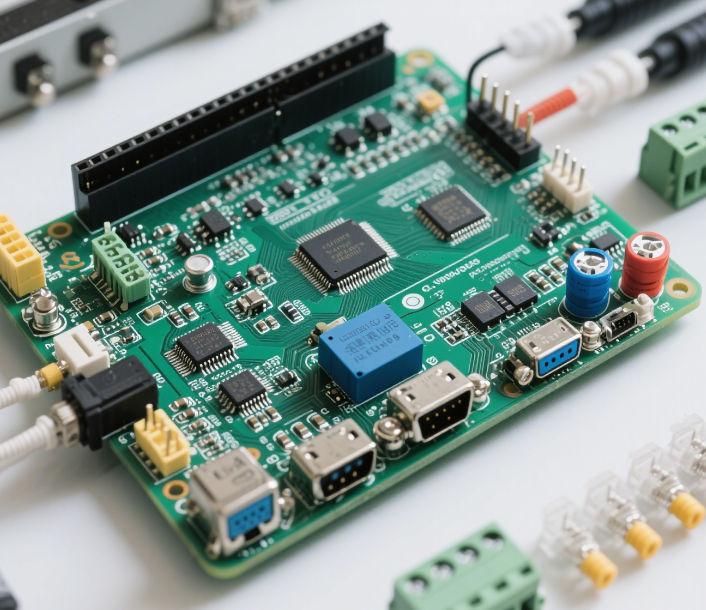

Industrial Control PCB Assembly

One-stop PCBA/EMS Intelligent Manufacturing Solution

Industrial Control PCB Assembly

Introduction

Industrial control is assembly refers to the process of designing, assembling, and testing printed circuit boards (PCBs) and electronic modules used in industrial automation, machinery control, and intelligent manufacturing systems. These assemblies serve as the core controllers for equipment such as PLCs (Programmable Logic Controllers), HMIs (Human-Machine Interfaces), servo drivers, sensors, and robotics.

Unlike consumer electronics, industrial control systems require high reliability, long lifecycle, and resistance to harsh environments such as high temperatures, humidity, vibrations, and electrical noise. As such, the assembly process involves strict quality standards, ruggedized components, and compliance with industrial certifications (e.g., IPC-A-610, ISO 9001, UL, CE).

Industrial control assemblies play a vital role in enabling automated production lines, real-time monitoring, predictive maintenance, and IoT connectivity—paving the way for Industry 4.0 and smart factories.

Importance of PCBs in Industrial Control

Printed Circuit Boards (PCBs) are the backbone of industrial control systems, providing the electrical and structural platform for controlling, monitoring, and automating machinery and production processes. Their importance in industrial control lies in several key areas:

1. Centralized System Control

PCBs enable precise integration of microcontrollers, sensors, actuators, and communication interfaces into a compact, reliable unit. They are at the heart of devices like:

• Programmable Logic Controllers (PLCs)

• Motor and drive controllers

• Human-Machine Interfaces (HMIs)

• Industrial IoT gateways

2. High Reliability and Durability

Industrial environments are often harsh—characterized by high temperature, humidity, vibration, and electrical noise. PCBs used in these settings must:

• Withstand thermal cycling and mechanical stress

• Offer long-term performance with minimal failure

• Be made from industrial-grade materials with protective coatings

3. Real-Time Communication and Automation

PCBs support fast data processing and transmission between equipment, enabling:

• Real-time control and monitoring

• Process automation and safety interlocks

• Integration with SCADA and MES systems

4. Customization and Integration

Industrial control PCBs are often custom-designed to meet unique system requirements, allowing:

• Multi-functional integration (control + communication + power)

• Compact and efficient layouts

• Adaptability to different industrial protocols (e.g., Modbus, CAN, Ethernet/IP)

5. Support for Industry 4.0 and Smart Manufacturing

With the rise of smart factories, PCBs now incorporate features like:

• Wireless connectivity (Bluetooth, Wi-Fi, LoRa)

• Edge computing capabilities

• Data logging and AI-driven fault prediction

In summary, PCBs are indispensable in industrial control, enabling the transition to automated, intelligent, and connected manufacturing systems.

Benefits of Industrial Control PCB Assembly

Industrial control PCB assembly provides the foundation for intelligent, reliable, and scalable automation systems. Below are the key advantages:

1. High Reliability in Harsh Environments

• Built to withstand extreme temperatures, vibration, dust, and moisture.

• Uses industrial-grade materials, conformal coating, and reinforced designs to ensure long-term operation in challenging conditions.

2. Precision and Real-Time Control

• Enables accurate signal processing and fast response times for real-time system monitoring and control.

• Essential for applications like robotics, CNC machines, conveyor systems, and safety interlocks.

3. Customizable and Scalable Designs

• Tailored to meet specific industry requirements and equipment layouts.

• Easily scaled from prototype to mass production for use in everything from small control units to large automation systems.

4. Compact and Integrated Functionality

• Supports multi-functional integration: power management, signal control, and communication all on one board.

• Reduces the need for multiple separate modules, saving space, cost, and complexity.

5. Support for Smart Manufacturing

• Enables connection to industrial networks (e.g., Modbus, PROFINET, EtherCAT).

• Integrates with sensors, edge computing, and IoT platforms to support Industry 4.0 initiatives.

6. Enhanced Safety and Compliance

• Designs follow strict standards like IPC-A-610, UL, ISO 9001, and RoHS.

• Incorporates redundancy, isolation, and fail-safe mechanisms for enhanced operational safety.

7. Cost Efficiency Over Lifecycle

• Although built to higher specs, industrial PCBs reduce long-term costs by offering:

• Fewer maintenance issues

• Lower downtime

• Longer operational life

Processes and Standards in PCB Manufacturing and Assembly

1. PCB Manufacturing Process

a. Design and File Preparation

Create schematics and PCB layout in CAD software.

Generate Gerber files, BOM, and NC drill files.

Perform DFM (Design for Manufacturability) check.

b. Substrate and Copper Cladding

Use FR-4, polyimide, or metal-core materials.

Apply copper foil to create base layers.

c. Inner Layer Imaging and Etching

Print circuit patterns using photoresist.

Etch away unwanted copper to form traces.

d. Layer Lamination

Stack and laminate layers under high pressure and heat.

e. Drilling

Drill holes for vias, through-holes, and mounting using CNC machines or lasers.

f. Plating and Surface Finishing

Copper plating for vias and through-holes.

Surface finishes like ENIG, HASL, OSP, or ENEPIG applied.

g. Solder Mask & Silkscreen

Apply solder mask to protect traces.

Print silkscreen for labels and orientation markers.

h. Electrical Testing

Use flying probe or bed-of-nails testing to verify continuity and insulation resistance.

2. PCB Assembly (PCBA) Process

a. Solder Paste Printing

Apply solder paste to pads using a stainless-steel stencil.

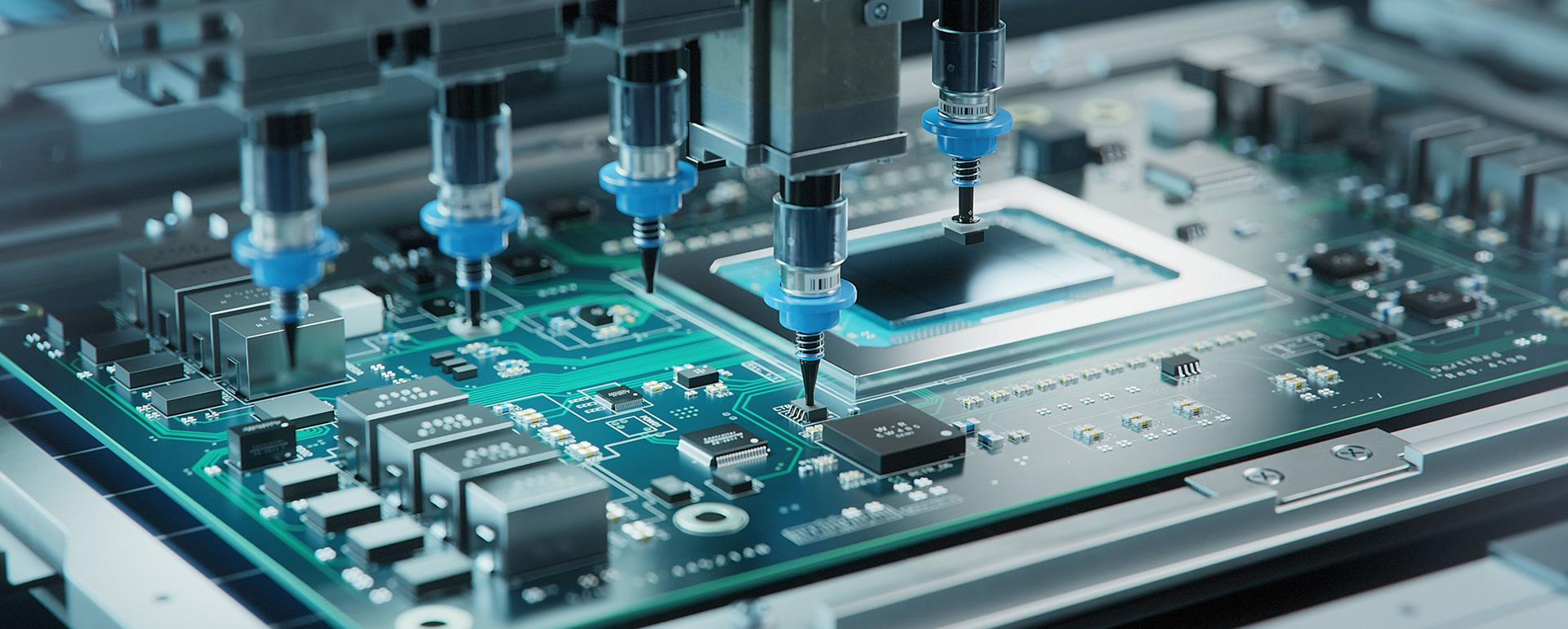

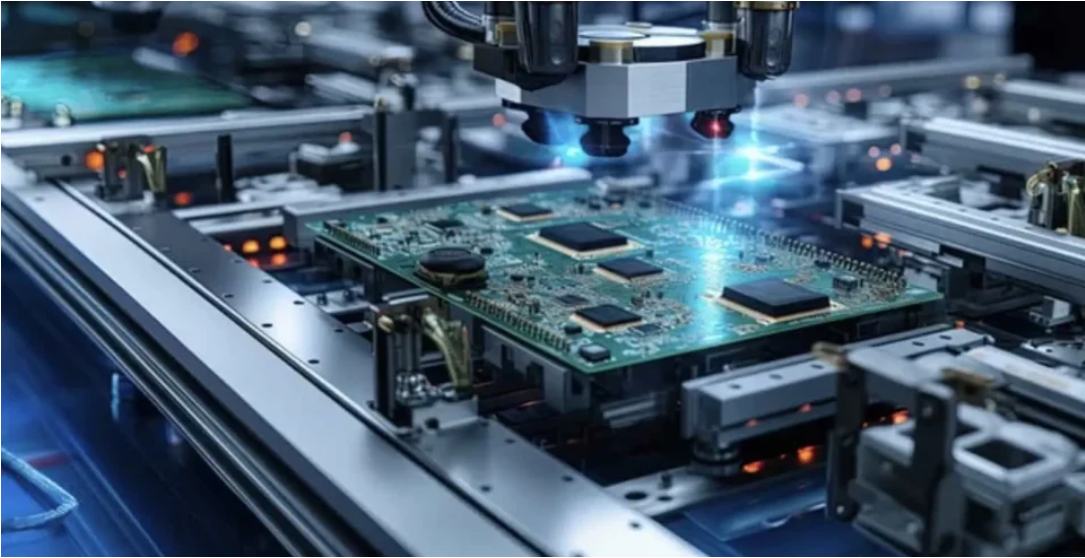

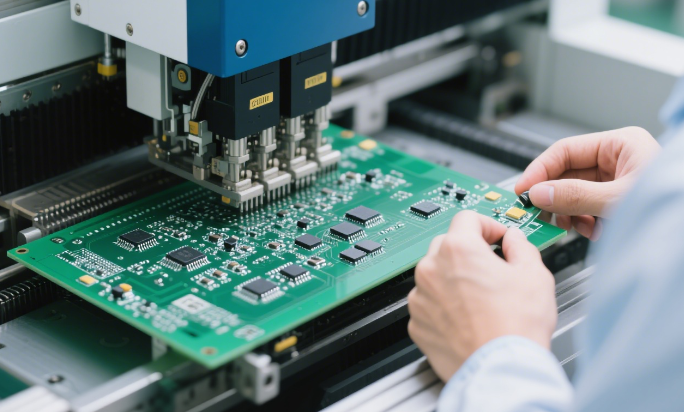

b. Pick and Place

SMT machines place components onto the board at high speed and accuracy.

c. Reflow Soldering

Boards go through a reflow oven to melt solder and secure components.

d. Through-Hole Insertion (if any)

Components placed manually or with auto-insertion machines.

e. Wave or Selective Soldering

Used for THT components; selective soldering preferred for mixed-technology boards.

f. Automated Optical Inspection (AOI)

Detects misplaced components, solder defects, and polarity issues.

g. X-ray Inspection (AXI)

Used for BGA, QFN, and hidden solder joints.

h. Functional Testing (FCT) and In-Circuit Testing (ICT)

Verifies that the board functions correctly under simulated working conditions.

3. Key Standards and Certifications

Manufacturing Standards

IPC-A-600: Acceptability of printed boards.

IPC-6012: Qualification and performance of rigid PCBs.

IPC-2221: Generic PCB design standards.

Assembly and Quality Standards

IPC-A-610: Acceptability of electronic assemblies.

IPC-7711/7721: Rework, modification, and repair standards.

Automotive/Industrial Standards

ISO 9001: Quality management systems.

IATF 16949: Automotive quality management.

ISO 26262: Functional safety for road vehicles.

UL, RoHS, and REACH: Safety and environmental compliance.

Summary

Implementing these structured processes and adhering to recognized standards ensures:

High reliability and performance

Long lifecycle of PCBs in industrial environments

Compliance with safety and environmental regulations

Consistency across prototyping and mass production

Challenges and Solutions in Industrial Control PCB Assembly

Industrial control PCB assemblies must operate reliably in demanding environments. This brings specific challenges that require well-engineered solutions during design, manufacturing, and testing.

1. Challenge: Harsh Operating Environments

Issues:

High temperatures, humidity, dust, vibration, and electrical noise

Risk of corrosion, mechanical failure, or signal disruption

Solutions:

Use high-temperature resistant materials (e.g., High Tg FR-4, Polyimide)

Apply conformal coatings (e.g., silicone, acrylic, parylene)

Design with reinforced solder joints and vibration-resistant mounting

2. Challenge: Electromagnetic Interference (EMI)

Issues:

Signal degradation or malfunction due to noise from nearby equipment

Solutions:

Add EMI shielding, ground planes, and ferrite beads

Maintain proper trace spacing and routing

Use differential signaling and filtered connectors

3. Challenge: Complex Multi-Function Integration

Issues:

Need for combining control, communication, and power on one PCB

Risk of layout congestion and thermal accumulation

Solutions:

Use multi-layer and HDI (High-Density Interconnect) designs

Implement thermal vias, copper pours, and heat sinks

Leverage rigid-flex PCBs for space-constrained applications

4. Challenge: High Mix, Low Volume Production

Issues:

Industrial applications often require custom or semi-custom PCBs

Short production runs increase cost and complexity

Solutions:

Work with EMS providers offering flexible production lines

Use modular design approaches and DFM/DFT optimization

Adopt quick-turn prototyping and agile development cycles

5. Challenge: Ensuring Long-Term Reliability

Issues:

Industrial PCBs must function reliably over 10+ years

Solutions:

Use automotive/industrial-grade components

Perform aging simulations, thermal cycling, and ESS (Environmental Stress Screening)

Maintain rigorous traceability and documentation

6. Challenge: Strict Compliance and Certification

Issues:

Need to comply with standards like IPC-A-610, ISO 9001, CE, UL, and RoHS

Solutions:

Partner with certified manufacturing facilities

Integrate automated testing (AOI, ICT, FCT) and quality control at each stage

Ensure all components meet RoHS/REACH and industrial-grade specs

Conclusion

By addressing these challenges through robust design, precise process control, and advanced testing, manufacturers can ensure that industrial control PCB assemblies deliver exceptional performance and reliability—even in the toughest environments.

Conclusion

Industrial control PCB assembly is a cornerstone of modern automation and smart manufacturing. With growing demands for precision, reliability, and connectivity, PCBs used in industrial control systems must meet stringent standards and perform consistently in challenging environments.

From design and material selection to manufacturing, testing, and certification, every step plays a vital role in ensuring the long-term performance and safety of industrial equipment. By addressing the unique challenges of harsh conditions, EMI, and multi-functional integration, manufacturers can build robust solutions that power factories, infrastructure, and intelligent systems around the world.

In the age of Industry 4.0, investing in high-quality industrial control PCBs isn’t just a technical choice—it’s a strategic advantage for achieving efficiency, uptime, and competitive edge.

Ready to Elevate Your PCB Projects to New Heights?

At EdgePCBA, we’re not just experts in PCB assembly and fabrication; we're your partners in innovation and success.

Whether you're building advanced automation systems, high-reliability industrial controllers, or smart IoT-enabled machines, choosing the right PCB assembly partner is critical to your success.

We offer:

• Expertise in industrial-grade PCB design and assembly

• Strict compliance with international standards (IPC, ISO, UL, RoHS)

• Robust testing, inspection, and quality assurance

• Flexible, scalable manufacturing—from prototypes to mass production

Let us help you bring your industrial control solutions to life with precision, reliability, and speed.

Contact us today to start your next project with confidence.