Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

Understanding Rigid-Flex PCBs: The Best of Both Worlds in Electronics

2026-01-29

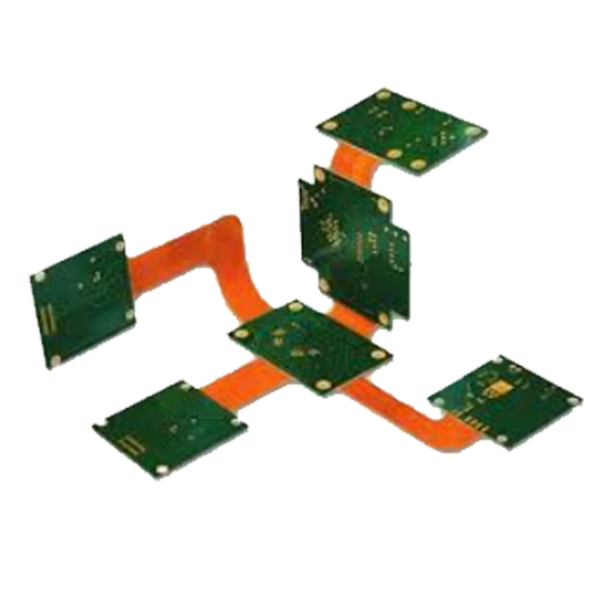

Rigid-flex PCBs, or rigid-flexible printed circuit boards, represent an innovative approach in the electronics industry, combining the features of both rigid and flexible PCBs into a single versatile solution. This hybrid technology has gained traction in various sectors, including telecommunications, medical devices, and consumer electronics, due to its ability to save space, reduce weight, and enhance reliability.

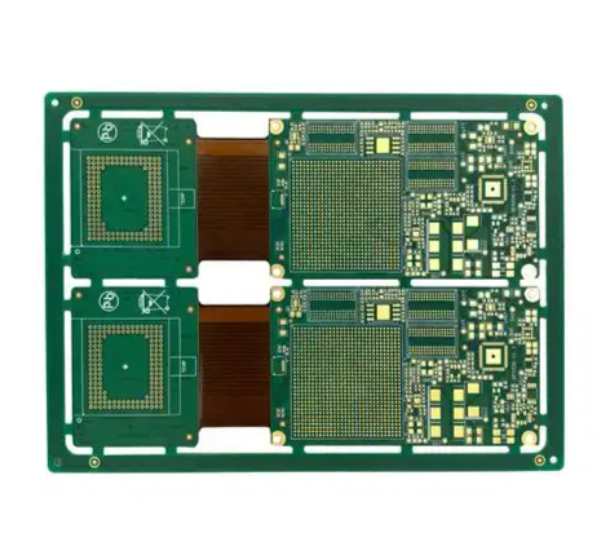

A rigid-flex PCB typically consists of multiple layers, including rigid components made from traditional PCB materials and flexible sections created from polyimide or similar materials. This construction allows manufacturers to design compact electronics that can bend and flex without compromising performance. Unlike standard rigid PCBs, which can be bulky and limited in terms of design flexibility, rigid-flex PCBs provide a unique solution for complex applications requiring intricate layouts.

One of the significant advantages of rigid-flex PCBs is their ability to minimize assembly time and costs. By integrating multiple components into a single board, manufacturers can reduce the number of interconnections and solder joints required, which ultimately leads to fewer points of failure. This streamlined manufacturing process enhances product reliability, making rigid-flex PCBs an ideal choice for mission-critical applications such as aerospace and medical instrumentation.

Moreover, the compact nature of rigid-flex PCBs allows for innovative designs that are critical in device miniaturization. As the demand for smaller and more efficient electronic devices continues to rise, the ability to incorporate rigid-flex technology into designs has become increasingly valuable. These boards can fit into tight spaces while maintaining performance, making them a preferred option for wearable technology, smartphones, and other compact devices.

In addition to design flexibility and reliability, rigid-flex PCBs offer superior performance in terms of thermal management and signal integrity. The materials used in rigid-flex designs are often better at dissipating heat and can support high-frequency applications, which is essential for modern electronics.

In conclusion, rigid-flex PCBs are revolutionizing the way electronic devices are designed and manufactured. Their unique combination of rigidity and flexibility provides engineers with the tools necessary to innovate and create advanced, compact solutions suitable for a wide range of applications. As the electronics industry continues to evolve, understanding the capabilities and advantages of rigid-flex PCBs will become increasingly critical for professionals in the field.

A rigid-flex PCB typically consists of multiple layers, including rigid components made from traditional PCB materials and flexible sections created from polyimide or similar materials. This construction allows manufacturers to design compact electronics that can bend and flex without compromising performance. Unlike standard rigid PCBs, which can be bulky and limited in terms of design flexibility, rigid-flex PCBs provide a unique solution for complex applications requiring intricate layouts.

One of the significant advantages of rigid-flex PCBs is their ability to minimize assembly time and costs. By integrating multiple components into a single board, manufacturers can reduce the number of interconnections and solder joints required, which ultimately leads to fewer points of failure. This streamlined manufacturing process enhances product reliability, making rigid-flex PCBs an ideal choice for mission-critical applications such as aerospace and medical instrumentation.

Moreover, the compact nature of rigid-flex PCBs allows for innovative designs that are critical in device miniaturization. As the demand for smaller and more efficient electronic devices continues to rise, the ability to incorporate rigid-flex technology into designs has become increasingly valuable. These boards can fit into tight spaces while maintaining performance, making them a preferred option for wearable technology, smartphones, and other compact devices.

In addition to design flexibility and reliability, rigid-flex PCBs offer superior performance in terms of thermal management and signal integrity. The materials used in rigid-flex designs are often better at dissipating heat and can support high-frequency applications, which is essential for modern electronics.

In conclusion, rigid-flex PCBs are revolutionizing the way electronic devices are designed and manufactured. Their unique combination of rigidity and flexibility provides engineers with the tools necessary to innovate and create advanced, compact solutions suitable for a wide range of applications. As the electronics industry continues to evolve, understanding the capabilities and advantages of rigid-flex PCBs will become increasingly critical for professionals in the field.

Related news