Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

Navigating Challenges in Communication for AIoT PCB Assembly: Strategies for Success

2026-02-01

Navigating Challenges in Communication for AIoT PCB Assembly: Strategies for Success

Table of Contents

- Introduction to AIoT and PCB Assembly

- Understanding AIoT: The Integration of AI and IoT

- The Significance of PCB Assembly in AIoT Applications

- Identifying Communication Challenges in AIoT PCB Assembly

- Effective Strategies for Enhancing Communication

- The Importance of Clear Documentation

- Utilizing Collaborative Tools for Team Integration

- Engaging Stakeholders Effectively

- Case Studies: Successful Communication in AIoT PCB Assembly

- Future Trends in AIoT PCB Assembly Communication

- Conclusion

- Frequently Asked Questions

Introduction to AIoT and PCB Assembly

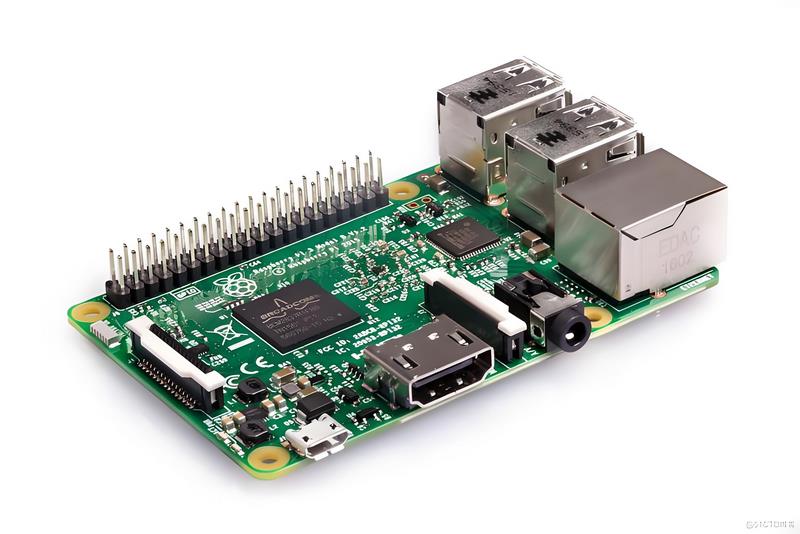

In today's digital age, the convergence of Artificial Intelligence (AI) and the Internet of Things (IoT) has given rise to a revolutionary paradigm known as AIoT. The integration of these technologies is not merely a trend; it is reshaping industries and redefining how electronic devices communicate and function. Central to this transformation is the Printed Circuit Board (PCB) assembly, a critical component that enables the connectivity and functionality of AIoT devices.

However, as we navigate the complexities of AIoT PCB assembly, one of the significant challenges we face is effective communication. Miscommunication can lead to severe implications, including project delays, increased costs, and decreased product quality. Therefore, understanding this challenge and developing strategies to overcome it is crucial for success in the AIoT landscape.

Understanding AIoT: The Integration of AI and IoT

AIoT represents the fusion of AI technologies with IoT systems to create smarter devices that not only collect data but also learn from it to make intelligent decisions. This amalgamation allows devices to communicate seamlessly, share information, and optimize their operations without human intervention.

For instance, in industrial applications, AIoT devices can predict equipment failures before they occur, leading to proactive maintenance and reducing downtime. The communication between these devices is vital; it ensures that data is transmitted accurately and promptly to facilitate real-time decision-making.

The Significance of PCB Assembly in AIoT Applications

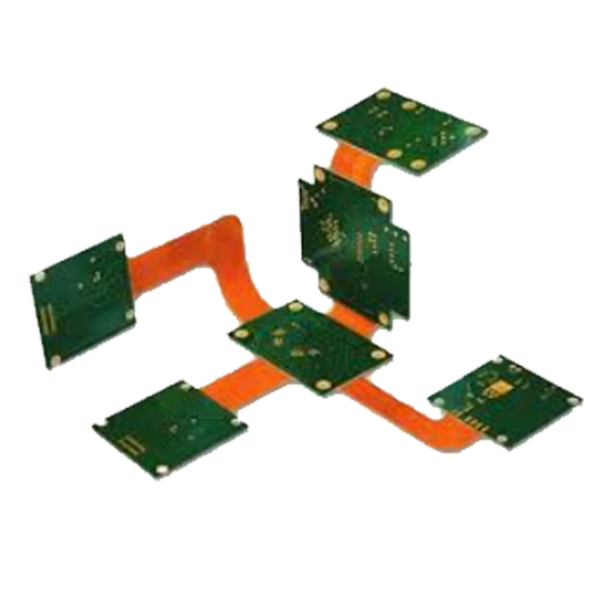

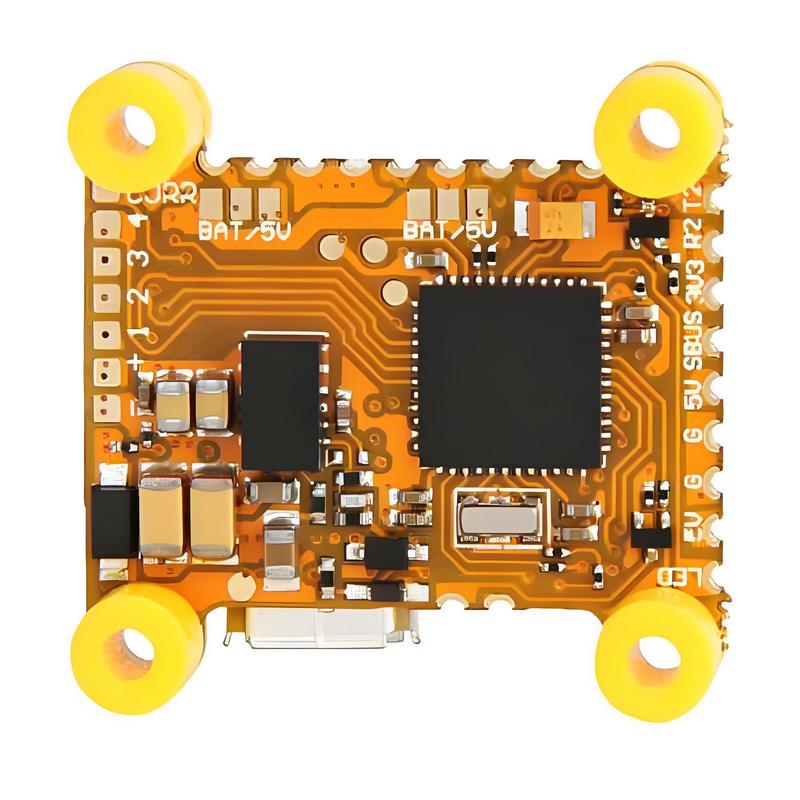

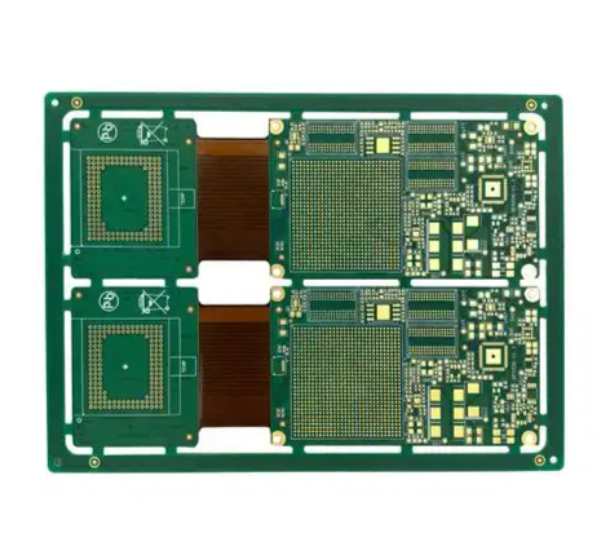

PCB assembly serves as the backbone of any electronic device, providing the necessary pathways for electrical signals and connections between different components. In AIoT applications, the complexity of PCBs increases due to the need to accommodate multiple sensors, microcontrollers, and communication modules.

Moreover, the reliability and efficiency of AIoT systems hinge on the quality of PCB assembly. A well-assembled PCB ensures that devices operate as intended and communicate effectively. As such, the PCB assembly process must be executed meticulously, with clear communication among all stakeholders involved.

Identifying Communication Challenges in AIoT PCB Assembly

As we delve into the intricacies of AIoT PCB assembly, several communication challenges emerge:

1. Diverse Stakeholder Involvement

AIoT projects often involve multiple stakeholders, including engineers, designers, manufacturers, and clients. Each party may have different priorities, technical jargon, and communication styles, leading to potential misunderstandings.

2. Technical Complexity

The technical nature of AIoT PCB assembly can create barriers to effective communication. Team members may struggle to convey complex concepts or specifications, resulting in misaligned expectations.

3. Geographic Dispersal

In an increasingly globalized market, teams may be spread across various locations, making real-time communication difficult. Time zone differences can further complicate collaborative efforts.

4. Rapid Technological Advancements

The pace of innovation in AIoT technology means that teams must continuously adapt. Keeping everyone informed about the latest developments is essential, yet can be challenging amidst busy schedules.

Effective Strategies for Enhancing Communication

To overcome these communication challenges, we can implement several effective strategies:

The Importance of Clear Documentation

Creating detailed documentation is crucial for ensuring that all team members are on the same page. This includes technical specifications, design files, and project timelines. Clear documentation helps mitigate misunderstandings and provides a reference point for team members to consult throughout the project lifecycle.

Utilizing Collaborative Tools for Team Integration

Leveraging collaborative tools can enhance communication and foster a sense of unity among team members. Platforms such as Slack, Microsoft Teams, and Asana enable real-time communication, file sharing, and task management, making it easier for team members to collaborate effectively, regardless of their location.

Engaging Stakeholders Effectively

Regularly engaging stakeholders in discussions about project goals, timelines, and expectations is vital. Scheduling regular meetings to provide updates and solicit feedback helps ensure alignment and fosters a collaborative environment. Additionally, using visual aids such as diagrams and flowcharts can aid in conveying complex information more clearly.

Case Studies: Successful Communication in AIoT PCB Assembly

Examining real-world examples can provide valuable insights into effective communication strategies.

Case Study 1: XYZ Tech Innovations

XYZ Tech Innovations, a leading AIoT device manufacturer, faced significant communication hurdles during a recent project. By implementing a centralized project management platform, they were able to streamline communication, resulting in a 30% reduction in project timelines. Regular check-ins and collaborative brainstorming sessions facilitated better understanding among team members and stakeholders, leading to a successful product launch.

Case Study 2: ABC Electronics

ABC Electronics encountered challenges with misaligned expectations during their PCB assembly process. To address this, they instituted a comprehensive documentation protocol that outlined every stage of the assembly process. This initiative not only improved communication but also led to higher quality control and reduced errors in the final product.

Future Trends in AIoT PCB Assembly Communication

As technology continues to evolve, the future of communication in AIoT PCB assembly will likely be shaped by several trends:

1. Increased Automation

The rise of automation in project management and communication tools will streamline processes and reduce the potential for human error. Automated updates and reminders can keep team members informed without the need for constant manual communication.

2. Advanced AI Integration

Artificial intelligence will play a more significant role in enhancing communication. AI-driven analytics can provide insights into team performance, identify communication bottlenecks, and suggest improvements.

3. Virtual Collaboration

With the increase in remote work, virtual collaboration tools will become even more sophisticated. Features such as augmented reality (AR) and virtual reality (VR) could facilitate real-time, immersive collaboration among team members, regardless of their location.

Conclusion

Navigating the challenges of communication in AIoT PCB assembly is essential for successful project execution. By understanding the complexities involved and implementing effective strategies, organizations can enhance collaboration, reduce misunderstandings, and ultimately deliver high-quality AIoT products. As technology continues to advance, staying proactive in communication will be crucial to thriving in the competitive landscape of AIoT.

Frequently Asked Questions

1. What is AIoT, and why is it important for PCB assembly?

AIoT combines Artificial Intelligence with the Internet of Things, enabling smarter devices that can communicate and operate autonomously. This integration enhances the functionality of PCB assemblies, making them essential for modern electronic applications.

2. What are the common communication challenges faced in AIoT PCB assembly?

Common challenges include diverse stakeholder involvement, technical complexity, geographic dispersal, and rapid technological advancements.

3. How can clear documentation improve communication in PCB assembly?

Clear documentation provides a point of reference for all team members, reducing misunderstandings and ensuring alignment on project specifications and goals.

4. What collaborative tools can help enhance communication among teams?

Tools like Slack, Microsoft Teams, and Asana facilitate real-time communication, file sharing, and task management, making it easier for teams to collaborate efficiently.

5. What role does stakeholder engagement play in successful AIoT projects?

Engaging stakeholders through regular updates and feedback sessions fosters alignment and collaboration, leading to improved project outcomes and satisfaction.

Related news