Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

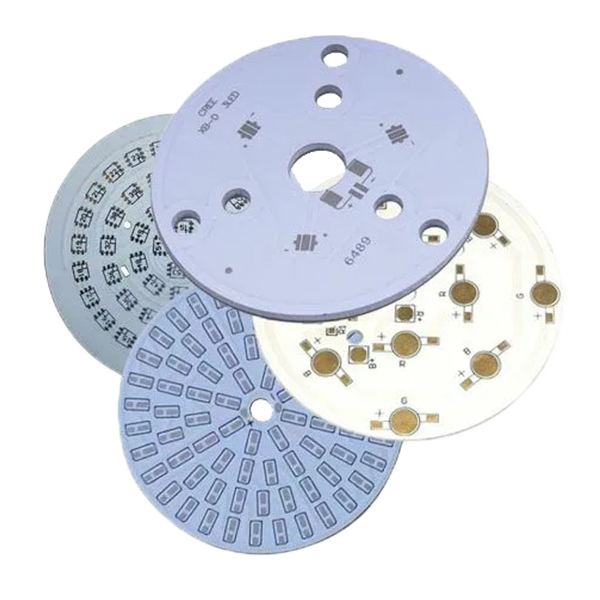

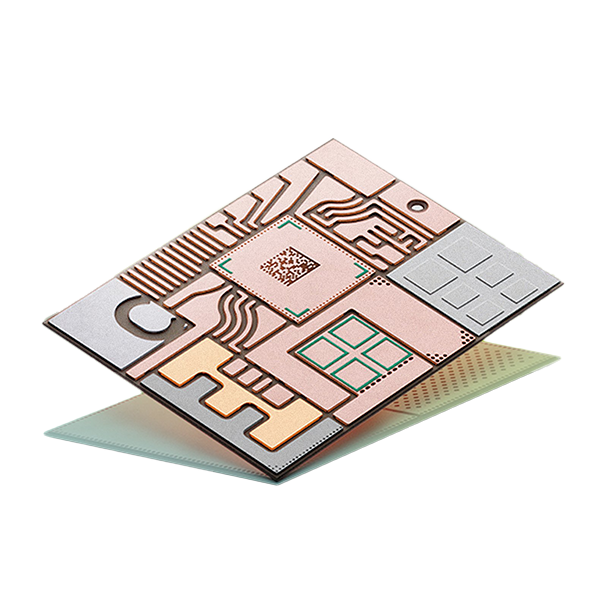

Ceramic PCB

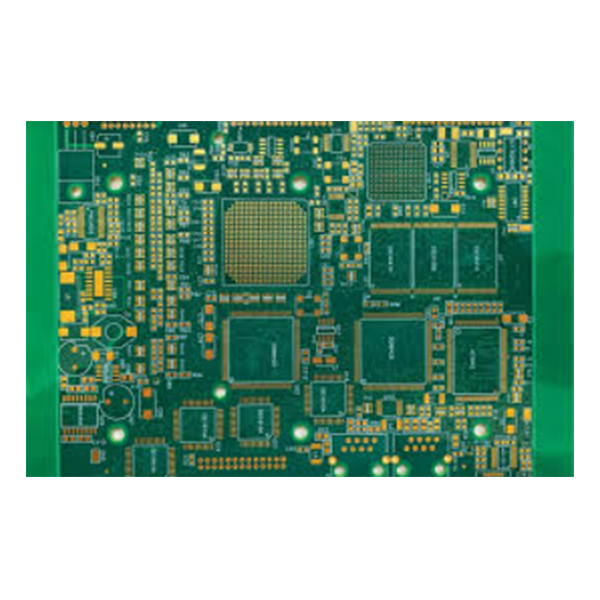

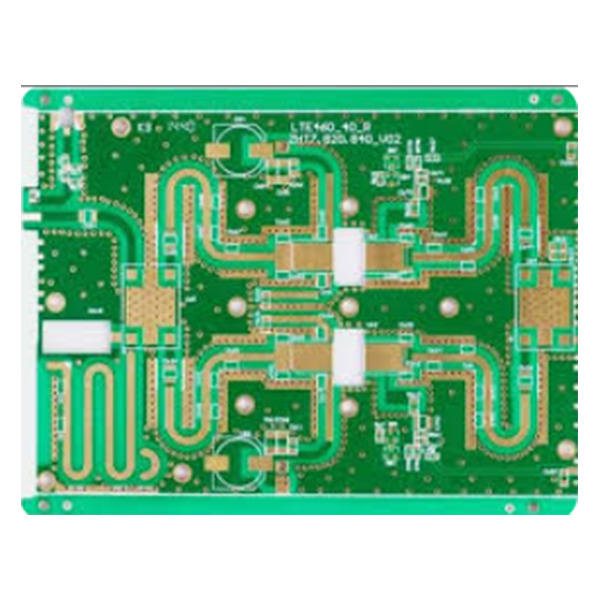

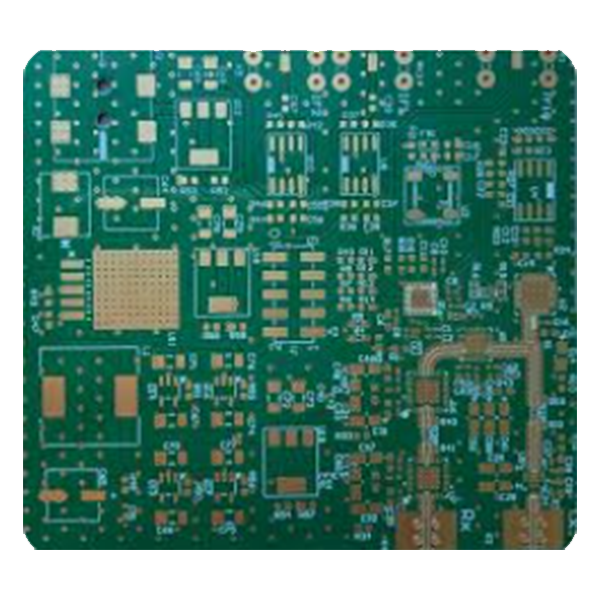

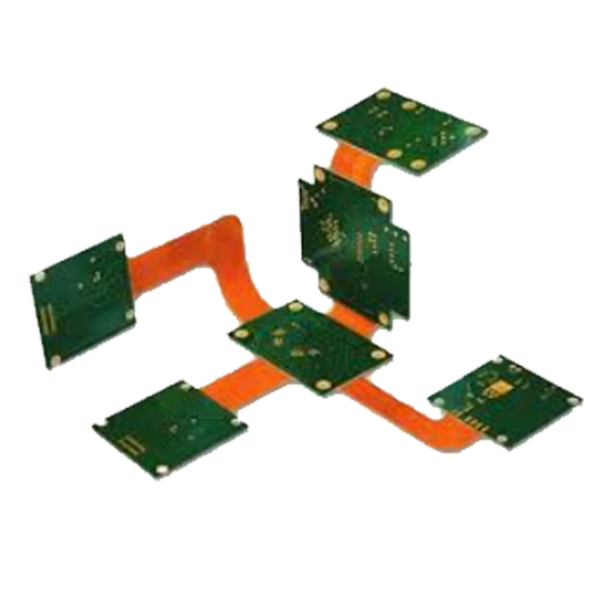

EdgePCBA manufactures ceramic printed circuit boards (PCBs).Ceramic PCBs are advanced printed circuit boards made using ceramic substrates such as Aluminum Oxide (Al₂O₃), Aluminum Nitride (AlN), or Beryllium Oxide (BeO). These boards offer excellent thermal conductivity, electrical insulation, and mechanical stability, making them ideal for high-power, high-frequency, and high-reliability applications.

Unlike traditional FR4-based boards, ceramic PCBs can withstand extreme environments and maintain performance in high-temperature or high-voltage scenarios.

|

|

Ceramic PCB Manufacturing ServicesHigh-performance printed circuit boards made with ceramic-based substrates such as aluminum oxide (Al₂O₃), aluminum nitride (AlN), or beryllium oxide (BeO). These materials offer superior thermal conductivity, electrical insulation, and mechanical stability, making them ideal for high-power, high-frequency, and high-reliability applications.

|

|

Why Choose Ceramic PCBs?High thermal conductivity, excellent electrical insulation, and reliable performance in harsh environments. They outperform traditional FR4 and even metal-core PCBs in many high-end and high-power scenarios.

|

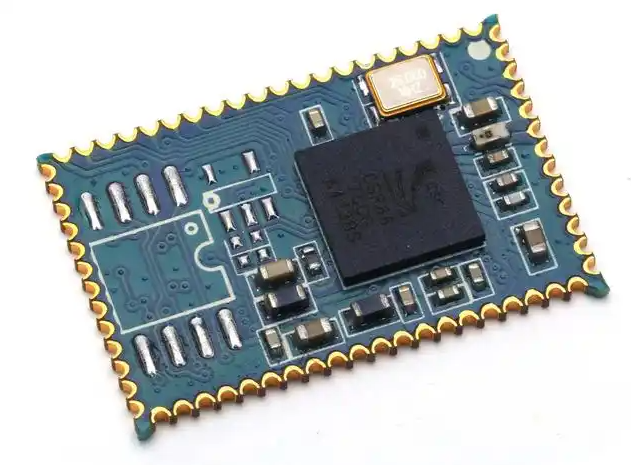

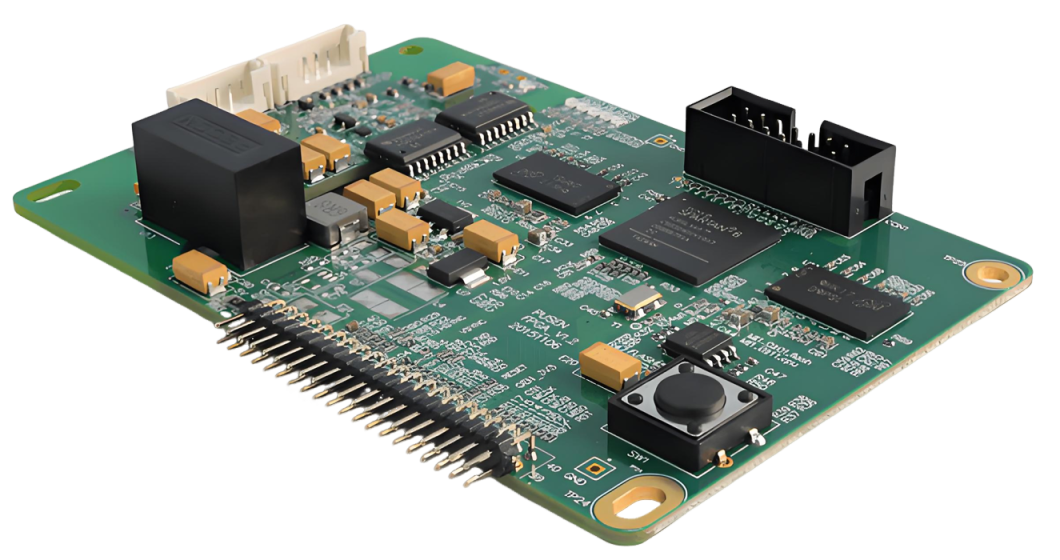

ASSEMBLY CAPABILITIES

Assembly Capabilities for PCBs

Stencil Size Range

29inch*29inch

SMT

Position accuracy: 25um

Components size:0201--150mm

Max.PCB Size:680mm*500mm

MinPCB size:50mm*50mm

Min.PCB Thickness:0.3mm-- 6mm

Min.IC Pitch: 0.30mm

Wave-Solder

Max.PCB width:450mm Min.PCB width:no Limited Component height: Top 120mm/Bottom 15mm

Min.BGA pitch

0.008"

Max.BGA Size

74mm x74mm

BGA Ball Pitch

1.00mm(Min);3.00mm(Max)

BGA Ball Diameter

0.40mm(Min);1.00mm(Max)

QFP Lead Pitch

0.38mm(Min);2.54mm(Max)

For further discussion about PCB Assembly, please contact us.

MATERIALS

Diversified PCB Assembly Materials You Can Choose

- FR-4

- Glass epoxy

- FR4 High Tg

- Rohs compliant

- Aluminum

- Rogers

- FR-4

- Glass epoxy

- FR4 High Tg

- Rohs compliant

- Aluminum

- Rogers

Assemble Your PCB Now!

Don't hesitate to reach out if you require any help or have specific customization requirements that we can cater to.