Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

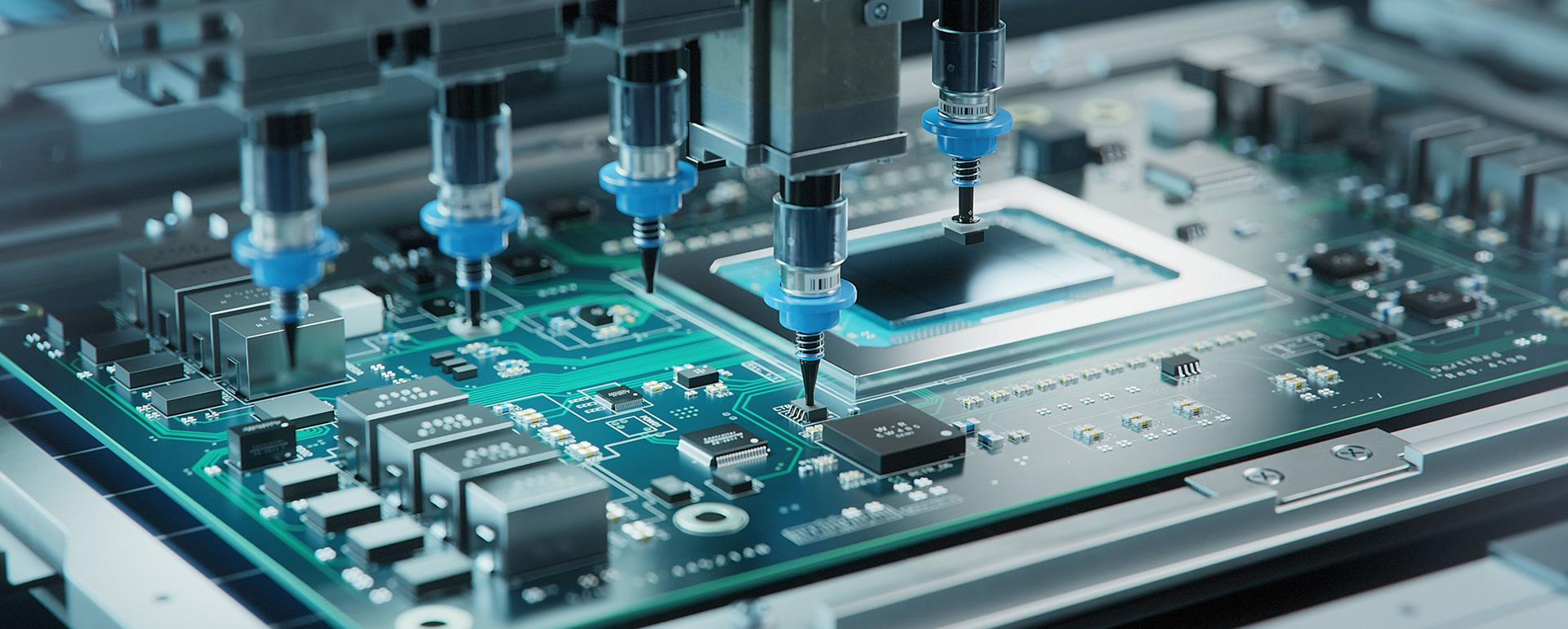

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

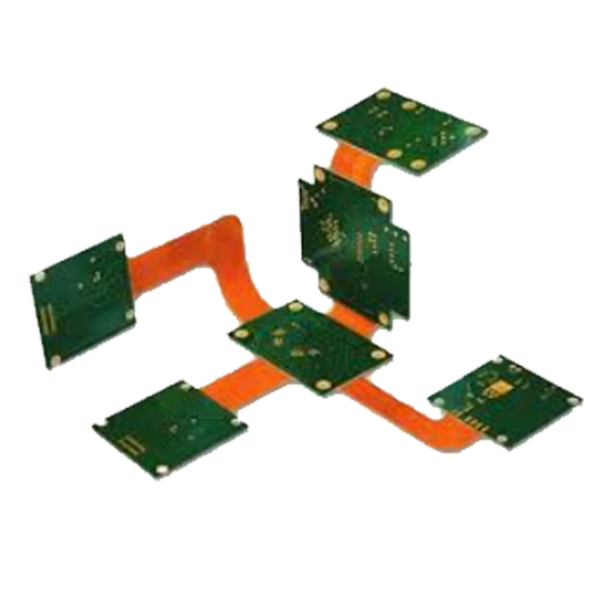

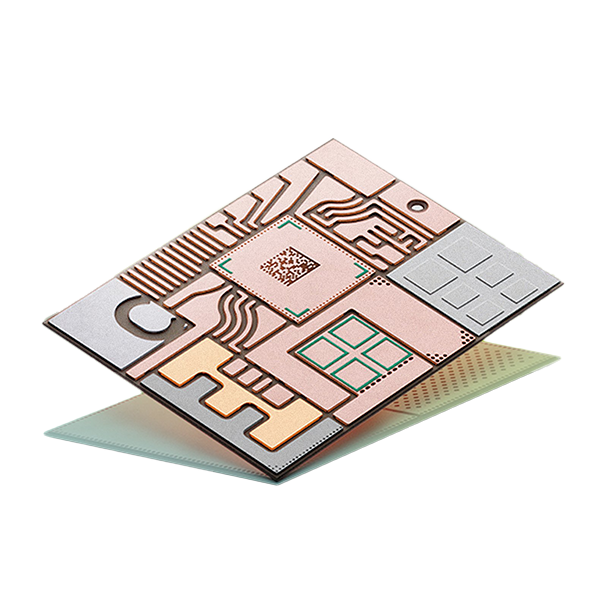

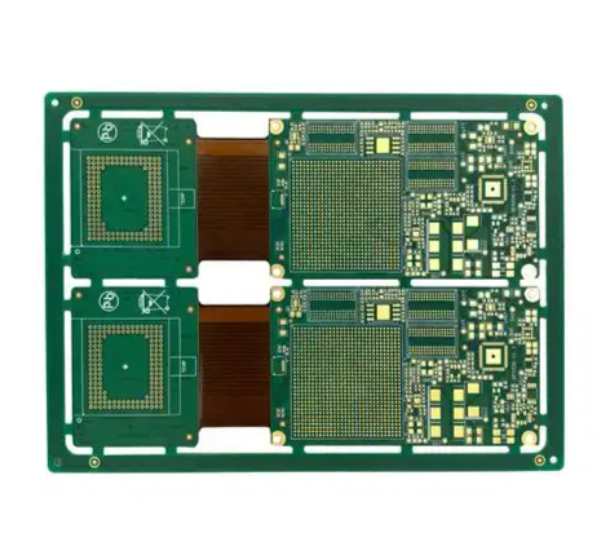

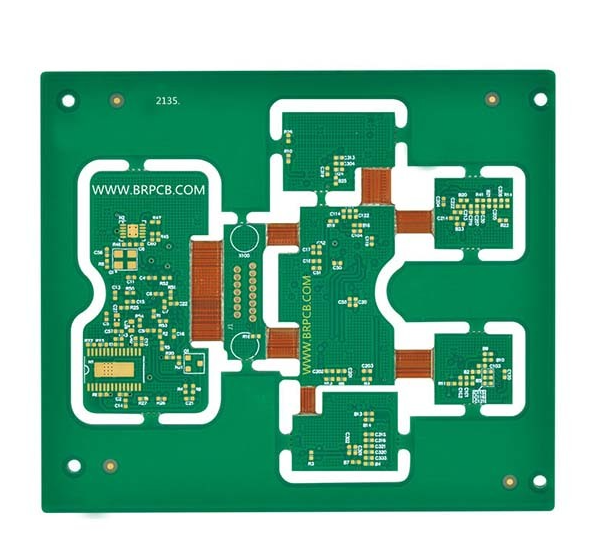

Rigid-flex PCB

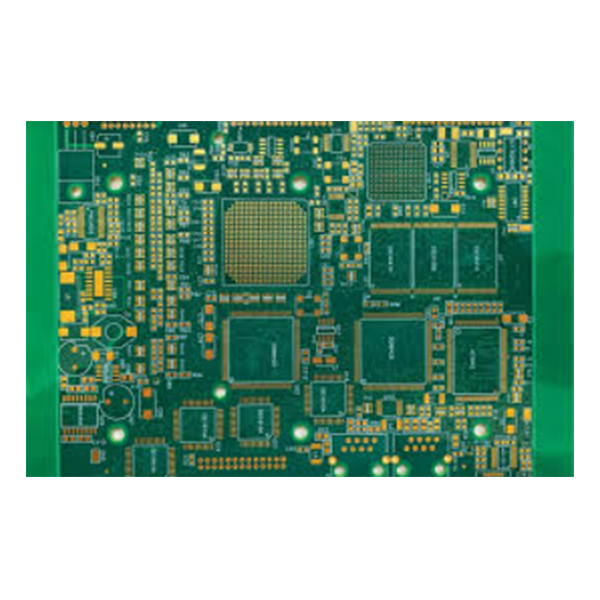

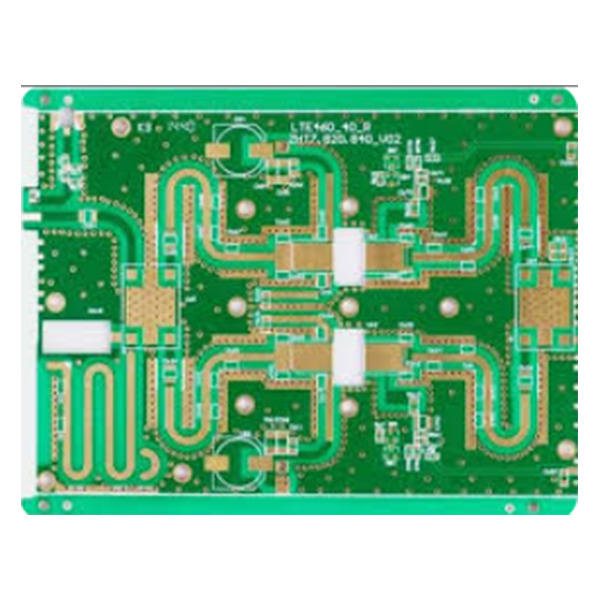

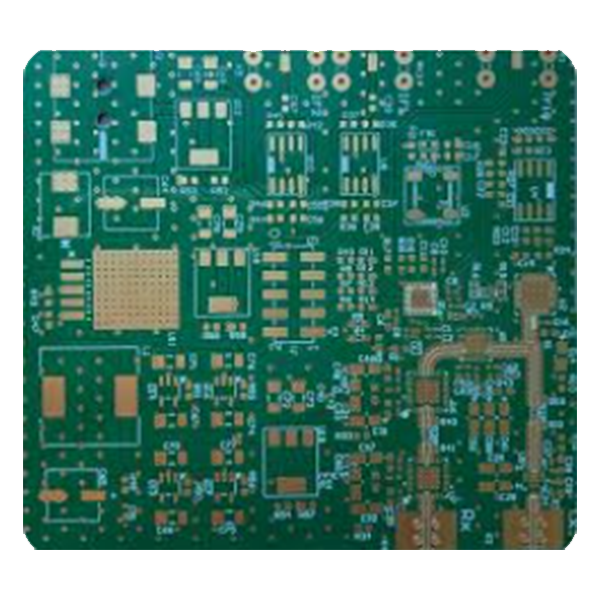

EdgePCBA provides Rigid-flex PCB services tailored to meet customer’s needs. Rigid-Flex PCBs combine the best of both rigid and flexible circuit board technologies into a single, hybrid structure. These boards consist of one or more flexible circuit layers integrated with rigid boards, allowing the design to bend and fold while maintaining structural stability in critical areas. This integration enables three-dimensional configurations, reduced weight, and increased reliability, making Rigid-Flex an ideal choice for compact, complex, and high-performance electronics.

|

|

What are Rigid-flex PCBs?Rigid-flex PCBs are a hybrid type of printed circuit board that combines the advantages of rigid boards and flexible circuits in a single integrated design. These PCBs are made by layering flexible circuit substrates with rigid boards, allowing for both bendable and solid sections within the same unit.

Key Characteristics:

|

|

Why Choose Rigid-Flex PCBs?Rigid-flex PCBs offer a powerful combination of mechanical flexibility, structural integrity, and space efficiency, making them an ideal solution for advanced electronic designs that demand both reliability and compactness.

Key Reasons to Choose Rigid-Flex PCBs:

|

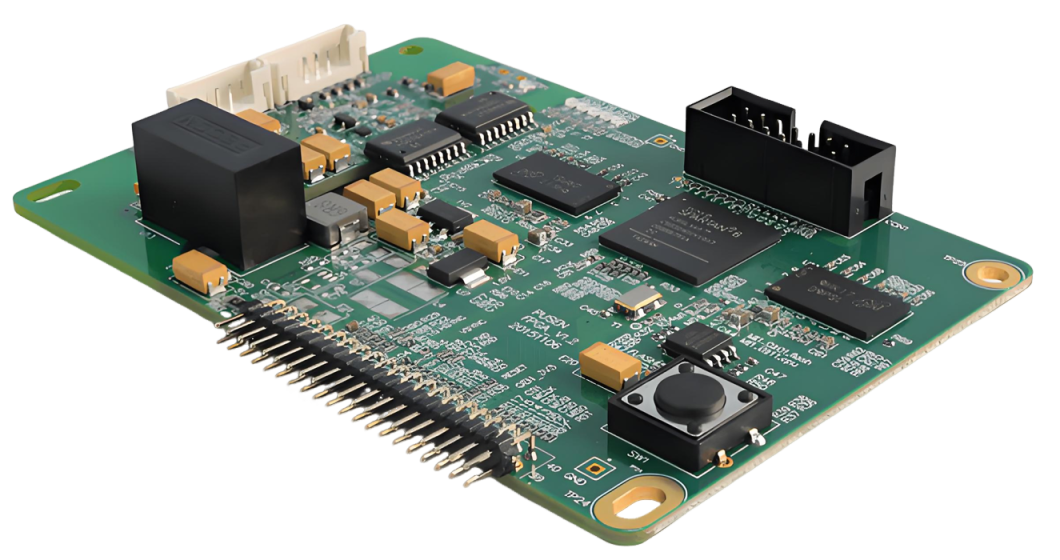

ASSEMBLY CAPABILITIES

Assembly Capabilities for PCBs

Stencil Size Range

29inch*29inch

SMT

Position accuracy: 25um

Components size:0201--150mm

Max.PCB Size:680mm*500mm

MinPCB size:50mm*50mm

Min.PCB Thickness:0.3mm-- 6mm

Min.IC Pitch: 0.30mm

Wave-Solder

Max.PCB width:450mm Min.PCB width:no Limited Component height: Top 120mm/Bottom 15mm

Min.BGA pitch

0.008"

Max.BGA Size

74mm x74mm

BGA Ball Pitch

1.00mm(Min);3.00mm(Max)

BGA Ball Diameter

0.40mm(Min);1.00mm(Max)

QFP Lead Pitch

0.38mm(Min);2.54mm(Max)

For further discussion about PCB Assembly, please contact us.

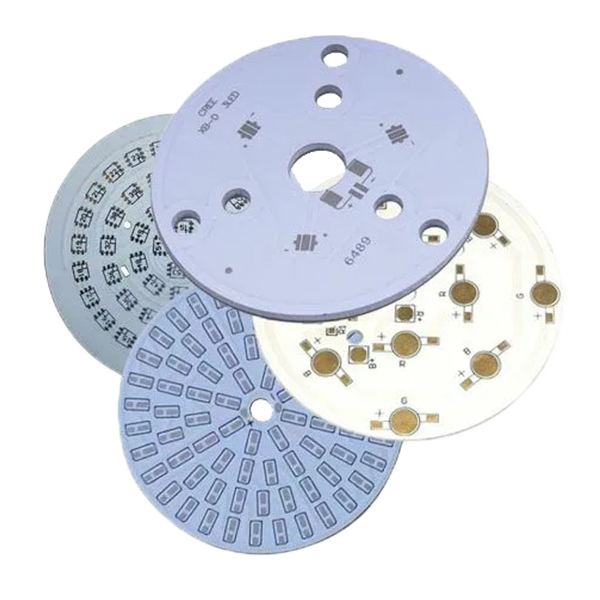

MATERIALS

Diversified PCB Assembly Materials You Can Choose

- FR-4

- Glass epoxy

- FR4 High Tg

- Rohs compliant

- Aluminum

- Rogers

- FR-4

- Glass epoxy

- FR4 High Tg

- Rohs compliant

- Aluminum

- Rogers

Assemble Your PCB Now!

Don't hesitate to reach out if you require any help or have specific customization requirements that we can cater to.