Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

Smart Home PCB Assembly

One-stop PCBA/EMS Intelligent Manufacturing Solution

Smart Home PCB Assembly

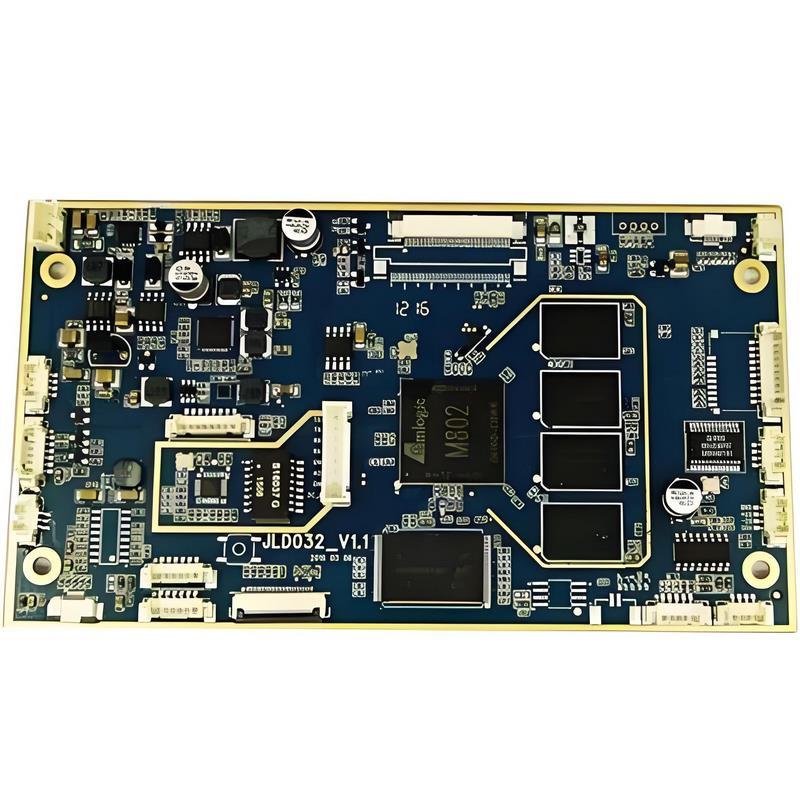

Key Components in Smart Home PCB Assembly

Smart home devices rely on advanced PCB assemblies that integrate a wide range of components to enable wireless communication, automation, sensing, and control. Below are the key components typically found in smart home PCB assemblies:

✅ 1. Microcontrollers (MCUs) / Microprocessors

Act as the brain of the device

Manage data processing, logic control, and communication

Common choices: ARM Cortex-M, ESP32, STM32, etc.

✅ 2. Wireless Communication Modules

Enable connection to smart home networks and cloud platforms

Wi-Fi, Bluetooth, Zigbee, Z-Wave, LoRa, or Thread modules

Example: ESP8266/ESP32, Nordic nRF52, Silicon Labs EFR32

✅ 3. Power Management ICs

Regulate and distribute power to different parts of the PCB

Includes voltage regulators, DC-DC converters, battery chargers, etc.

Supports AC-DC or DC-DC conversion depending on application

✅ 4. Sensors

Allow devices to detect environmental changes or user actions

Common types:

Motion sensors (PIR)

Temperature & humidity sensors (DHT11, SHT31)

Light sensors (LDR, TSL2561)

Gas or smoke sensors (MQ-series)

✅ 5. Actuators & Relays

Control external devices like lights, fans, door locks, and appliances

Includes mechanical relays, solid-state relays, and MOSFETs

✅ 6. Memory Components

Store firmware, user data, or device configurations

Includes Flash, EEPROM, or SD card interfaces

✅ 7. User Interface Components

Allow user interaction with the device

Includes LED indicators, buttons, touch sensors, and displays (OLED/LCD)

✅ 8. Connectors and Interfaces

For power input, communication ports (USB, UART, I²C, SPI), or firmware updates

May also include antennas or test/debug headers

✅ 9. Protection Components

Ensure device safety and longevity

Includes TVS diodes, fuses, ESD protection, and reverse polarity protection

The Smart Home PCB Assembly Process

Smart home devices require precise and reliable PCB assembly to ensure seamless operation of functions like wireless communication, sensor control, power management, and automation. The assembly process typically follows these key steps:

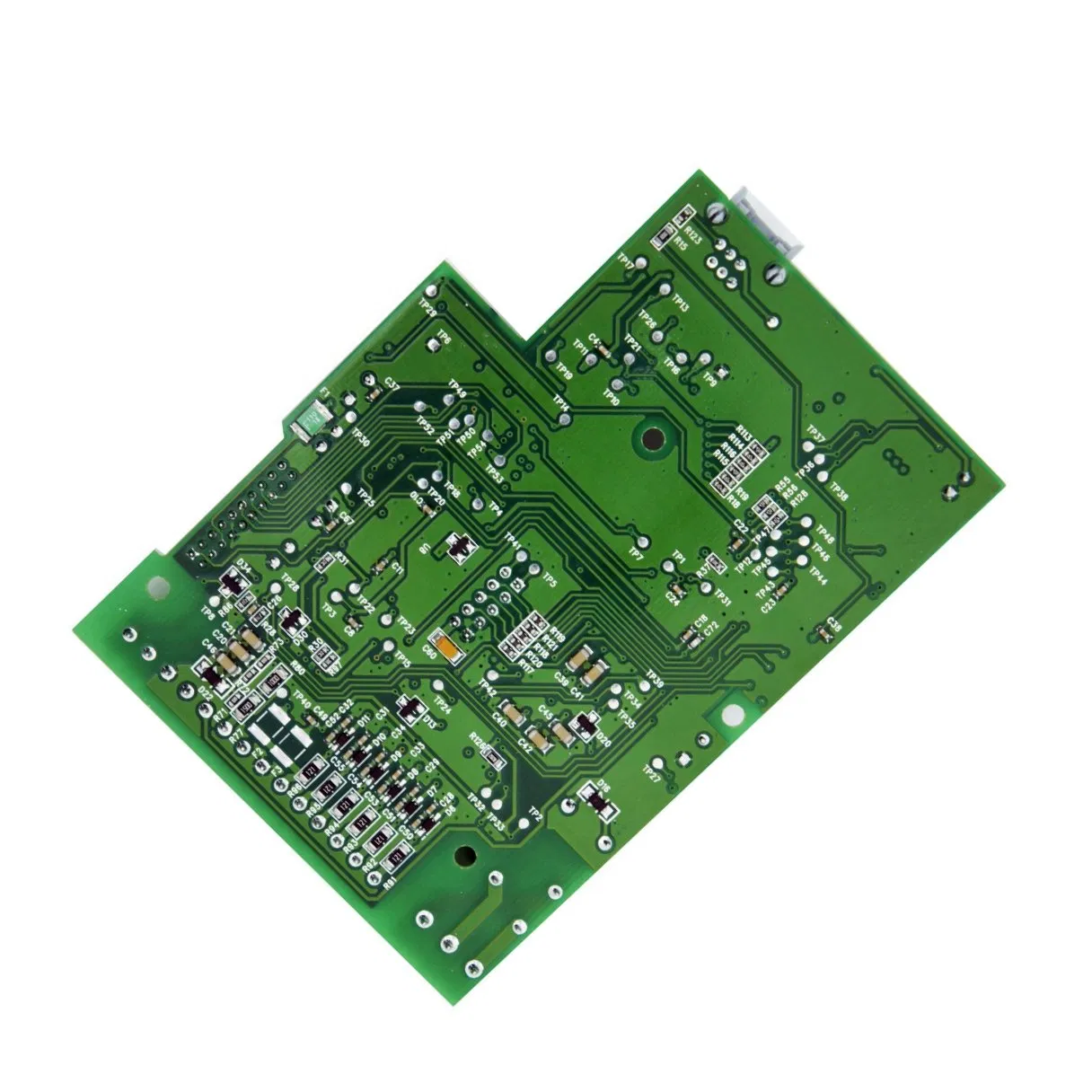

✅ 1. PCB Design & Material Selection

Design Phase: Involves schematics, PCB layout, and stack-up planning using EDA software (e.g., Altium, KiCAD, Eagle).

Material Selection: Choice of PCB substrate (FR4, metal core, etc.) depends on power and thermal requirements.

✅ 2. Component Sourcing & BOM Procurement

Select and procure components such as MCUs, RF modules, sensors, relays, and passives based on the Bill of Materials (BOM).

Ensure compatibility, lead time, and availability for mass production.

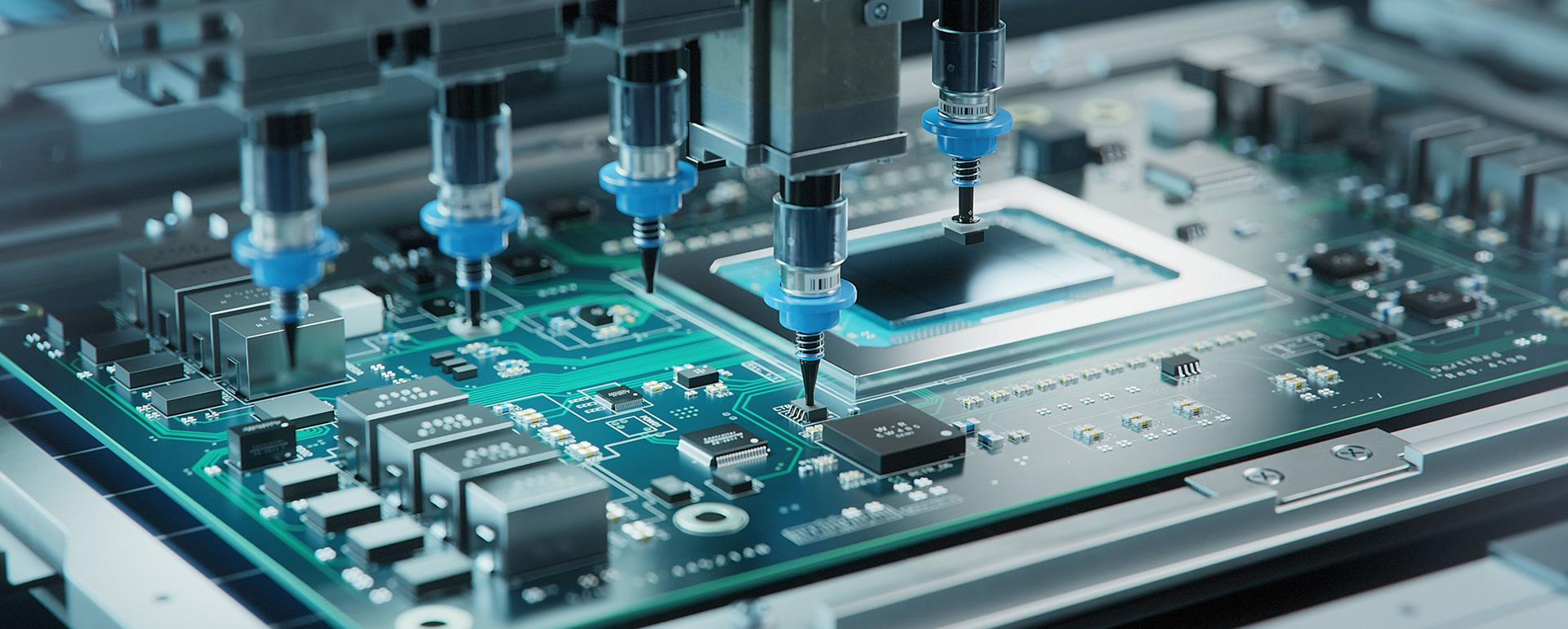

✅ 3. SMT (Surface Mount Technology) Assembly

Solder Paste Printing: A stencil printer applies solder paste to pads on the PCB.

Pick and Place: High-speed machines accurately place surface-mount components (resistors, capacitors, ICs, etc.).

Reflow Soldering: Boards pass through a reflow oven where solder paste melts and forms reliable solder joints.

✅ 4. THT (Through-Hole Technology) Assembly (if needed)

Components like relays, connectors, or transformers are inserted manually or via automated insertion.

Wave soldering or selective soldering is used to solder these parts.

✅ 5. Inspection & Quality Control

Automated Optical Inspection (AOI): Detects placement issues, missing components, or solder defects.

X-ray Inspection: Used for BGA and hidden joints.

Visual Inspection & Microscopy: Manual inspection of critical zones.

Functional Testing (FCT): Verifies that the board operates according to smart home device specs (Wi-Fi pairing, sensor readings, etc.).

✅ 6. Programming & Firmware Upload

Microcontrollers or SoCs are programmed with the device’s firmware using ISP, JTAG, or test points.

Configuration for network protocols (e.g., Wi-Fi, Zigbee) may be done here.

✅ 7. Final Assembly & Integration

The PCB is integrated into the device housing.

Additional steps may include attaching antennas, wiring connectors, or installing batteries.

✅ 8. Burn-In & Environmental Testing (optional but recommended)

Long-term reliability tests, including thermal cycling, humidity exposure, or vibration testing, to simulate real-world use.

✅ 9. Packaging & Delivery

Assembled boards are cleaned, labeled, and packed in ESD-safe packaging.

Ready for final device assembly or direct shipment.

Benefits of Smart Home PCB Assembly

Smart Home PCB assembly integrates advanced electronics into compact, intelligent systems that enable connectivity, automation, and remote control of household devices. Here are the key benefits:

✅ 1. Compact and Space-Efficient Designs

Smart home PCB assemblies are highly integrated, combining sensors, processors, power management, and wireless modules onto a single board. This supports miniaturized devices like smart thermostats, switches, and security sensors without sacrificing performance.

✅ 2. Seamless Wireless Connectivity

Integrated modules (Wi-Fi, Zigbee, Bluetooth, Thread) allow reliable wireless communication with other smart devices and cloud platforms, enabling smooth operation and remote control via smartphones, voice assistants, or automation hubs.

✅ 3. Energy Efficiency

Smart PCBs can be designed to optimize power usage, utilizing ultra-low-power components, efficient regulators, and sleep modes. This is crucial for battery-powered devices like door/window sensors and remote controllers.

✅ 4. Improved Reliability and Durability

With fewer connectors and cables, smart PCB assemblies reduce failure points, improve mechanical integrity, and are better suited for long-term deployment in home environments.

✅ 5. Faster Time to Market

Streamlined PCB assembly using SMT automation and turnkey services allows for rapid prototyping and production, helping brands launch smart home products faster.

✅ 6. High Customizability

Smart home PCBs can be tailored to specific applications, such as lighting control, security, HVAC, or entertainment, with custom firmware, interface options, and sensor configurations.

✅ 7. Supports IoT Integration and Automation

Well-designed PCB assemblies serve as the foundation for IoT-enabled ecosystems, allowing devices to share data, adapt to user behavior, and trigger automated routines (e.g., lights turning on when motion is detected).

✅ 8. Cost-Effective for Scaled Production

Once design is finalized, automated PCB assembly helps reduce production costs through volume manufacturing, optimized layouts, and reduced component waste.

Applications and Use Cases

Smart home PCB assemblies power a wide variety of intelligent devices that enhance comfort, security, energy efficiency, and connectivity within modern living environments. These PCBs are custom-designed to integrate sensors, communication modules, microcontrollers, and power systems into compact and reliable solutions.

🏠 1. Smart Lighting Systems

Use Cases:

oDimmable LED lights

oMotion-activated lighting

oRemote or app-controlled light switches

oAmbient lighting with color control (RGB)

Features Enabled by PCB Assembly:

Integrated dimmer ICs, Bluetooth/Zigbee modules, power regulation, touch or motion sensors

🔐 2. Smart Security & Access Control

Use Cases:

oVideo doorbells

oSmart locks and access keypads

oWindow/door sensors

oMotion detectors and intruder alarms

PCB Features:

Camera modules, microcontrollers, wireless connectivity, battery power management, PIR sensors

🎛️ 3. Smart Climate & Environment Control

Use Cases:

oSmart thermostats

oSmart HVAC controllers

oAir quality and CO2 sensors

oHumidifiers/dehumidifiers with app control

PCB Features:

Temperature/humidity sensors, Wi-Fi or Zigbee modules, LCD display integration, power relays

🔊 4. Voice Assistants & Smart Speakers

Use Cases:

oDevices like Amazon Echo, Google Nest, etc.

oSmart control hubs for home automation

PCB Features:

Microphone arrays, voice recognition chips, Wi-Fi/Bluetooth, speaker amplifiers, LEDs

🔌 5. Smart Power Management

Use Cases:

oSmart plugs and power strips

oEnergy monitoring systems

oSolar/battery backup controllers

PCB Features:

Current sensors, relays, voltage regulators, wireless modules, user interface components

📺 6. Smart Entertainment & Media

Use Cases:

oSmart TVs

oStreaming boxes

oMulti-room audio systems

PCB Features:

HDMI interfaces, Wi-Fi/Bluetooth, audio DACs, infrared receivers, CPU/MCU for signal processing

🚗 7. Integration with Other IoT Devices

Use Cases:

oCross-platform automation (e.g., lights turn on when door opens)

oRemote monitoring of home systems

oVoice or app-based scene controls

PCB Features:

Inter-device communication via MQTT, Thread, or Matter protocols; cloud integration

Conclusion

Smart home technology continues to transform the way we live—bringing convenience, efficiency, and intelligence into everyday life. At the heart of this innovation lies the smart home PCB assembly, which enables seamless integration of sensors, wireless connectivity, and control logic into compact, efficient, and reliable devices.

Whether you're developing smart lighting systems, security devices, or climate control solutions, a well-designed PCB is crucial for performance, scalability, and user satisfaction. Choosing a trusted PCB manufacturing and assembly partner ensures not only quality and durability, but also faster time-to-market and long-term cost savings.

As the smart home industry grows, investing in high-quality, customized PCB assembly services is key to delivering competitive, future-ready products that meet the evolving demands of connected living.

Ready to Elevate Your PCB Projects to New Heights?

Whether you're developing advanced smart home devices, high-speed communication systems, or next-generation IoT solutions, we’re here to help you bring your ideas to life.

With our expertise in rigid, flexible, metal, ceramic, and high-speed PCB assembly, we deliver high-quality, scalable solutions tailored to your exact requirements.

📩 Contact us today to discuss your project — and discover how our reliable manufacturing services can power your next breakthrough.