Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

Achieving Precision in UAV PCB Assembly: Techniques That Work

2026-02-19

Achieving Precision in UAV PCB Assembly: Techniques That Work

Table of Contents

- Understanding UAV PCB Assembly

- Importance of Precision in UAV Applications

- Key Techniques for Precision in UAV PCB Assembly

- Design Considerations for Precision

- Material Selection for Optimal Performance

- Advanced Manufacturing Processes

- Quality Control Measures

- Emerging Technologies in UAV PCB Assembly

- Common Challenges in UAV PCB Assembly Precision

- Best Practices for UAV PCB Assembly

- FAQs

- Conclusion

Understanding UAV PCB Assembly

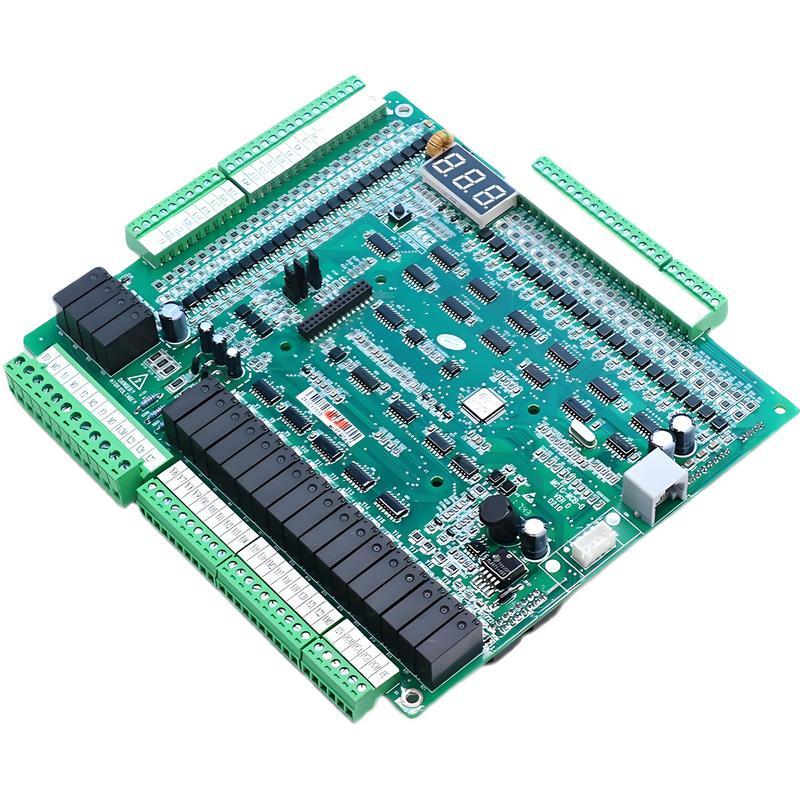

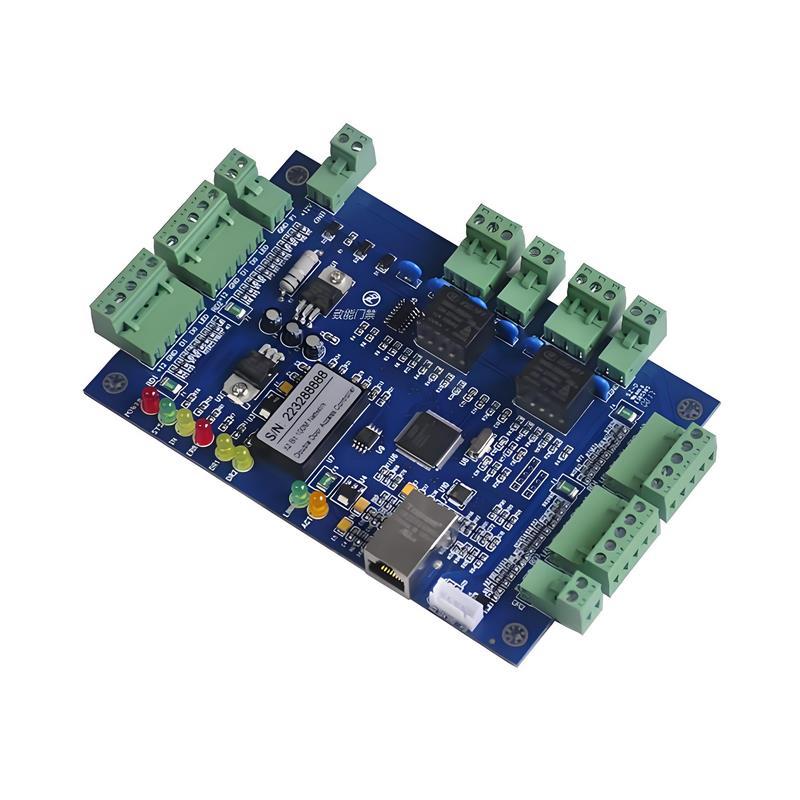

Unmanned Aerial Vehicles (UAVs), commonly referred to as drones, have revolutionized various industries, from agriculture to surveillance. The backbone of these sophisticated machines lies in their **printed circuit boards (PCBs)**, which form the electrical foundation that ensures functionality and performance. **UAV PCB assembly** is a meticulous process that involves the integration of various electronic components onto a PCB, enabling the UAV to execute its designated tasks effectively.

Importance of Precision in UAV Applications

Precision in UAV PCB assembly is not merely a technical requirement; it is critical for the operational reliability and safety of the UAVs. Given their applications in sensitive environments, such as military operations or search and rescue missions, any deviation in PCB assembly can lead to malfunctions or failures. Therefore, achieving high precision is crucial for:

- Ensuring accurate navigation and control systems.

- Enhancing communication reliability between the UAV and its operators.

- Maintaining the integrity of data collected during missions.

Key Techniques for Precision in UAV PCB Assembly

To achieve the desired precision in UAV PCB assembly, several key techniques and methodologies must be employed:

Design Considerations for Precision

The design phase is the foundation for precision in **UAV PCB assembly**. Engineers should consider:

- Layout Optimization: A well-organized layout minimizes signal interference and enhances the performance of electronic components.

- Thermal Management: Efficient thermal dissipation designs prevent overheating of components, ensuring longevity and reliability.

- Signal Integrity: Techniques such as controlled impedance routing and minimizing trace lengths can greatly enhance signal integrity.

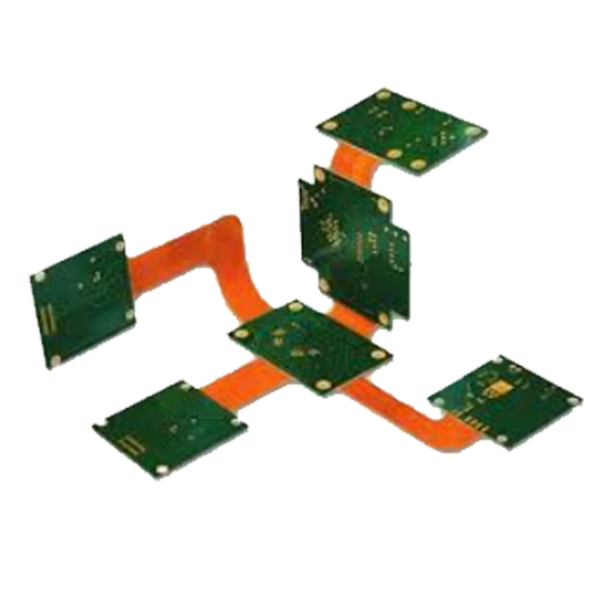

Material Selection for Optimal Performance

The choice of materials used in PCB manufacturing directly impacts the precision and reliability of UAVs. Key considerations include:

- Substrate Material: Selecting high-quality substrates that offer stable thermal and electrical properties is essential.

- Component Quality: Utilizing high-grade components that are specifically designed for UAV applications can prevent failures.

- Surface Finish: Appropriate finishes such as ENIG (Electroless Nickel Immersion Gold) provide better solderability and corrosion resistance.

Advanced Manufacturing Processes

Adopting advanced manufacturing techniques is vital for enhancing the precision of UAV PCB assembly. These include:

- Automated Pick and Place Technology: This technology ensures accurate placement of components, reducing human error significantly.

- Reflow Soldering: Utilizing controlled reflow processes helps in achieving strong, reliable solder joints.

- Laser Cutting and Drilling: These methods provide high precision in component placement and PCB dimensions.

Quality Control Measures

Implementing stringent quality control measures is essential for ensuring precision in UAV PCB assembly. This includes:

- In-Process Inspections: Regular inspections during the assembly process can identify issues early, preventing costly reworks.

- Final Testing: Comprehensive testing, including functional and stress tests, guarantees that the assembled PCB meets the required specifications.

- Certification Compliance: Adhering to industry standards such as IPC-A-610 ensures that assemblies meet global quality benchmarks.

Emerging Technologies in UAV PCB Assembly

The landscape of UAV PCB assembly is continually evolving with the introduction of emerging technologies that enhance precision and efficiency:

- 3D Printing: This technology allows for rapid prototyping of complex PCB designs.

- IoT Integration: Incorporating Internet of Things (IoT) technology in PCB design facilitates remote monitoring and diagnostics.

- AI and Machine Learning: These technologies can predict potential failures and optimize assembly processes for better outcomes.

Common Challenges in UAV PCB Assembly Precision

Despite advancements in technology, UAV PCB assembly still faces several challenges that can impact precision:

- Component Miniaturization: Smaller components require more precise handling and placement, increasing the risk of errors.

- Environmental Factors: Factors such as humidity and temperature fluctuations can affect PCB performance.

- Complex Designs: High-density designs with intricate layouts pose significant challenges in maintaining precision.

Best Practices for UAV PCB Assembly

Adhering to best practices can significantly improve precision in UAV PCB assembly:

- Invest in Training: Ensure that all personnel involved in the assembly process receive proper training and are familiar with the latest technologies.

- Regular Equipment Maintenance: Keep machinery and tools in optimal condition to prevent errors during the assembly process.

- Collaborate with Experts: Engaging with specialists in UAV technology can provide insights that enhance the assembly process and design.

FAQs

What is UAV PCB assembly?

UAV PCB assembly refers to the process of integrating electronic components onto printed circuit boards specifically designed for Unmanned Aerial Vehicles.

Why is precision important in UAV PCB assembly?

Precision is crucial to ensure the reliability and functionality of UAVs, especially in critical applications where any failure can lead to significant consequences.

What materials are best for UAV PCBs?

High-quality substrates with excellent thermal and electrical properties, along with sturdy, reliable components, are recommended for UAV PCBs.

How can quality control be implemented in UAV PCB assembly?

Quality control can be achieved through in-process inspections, final testing, and adherence to industry standards for PCB assembly.

What are some common challenges in UAV PCB assembly?

Challenges include component miniaturization, environmental impacts, and the complexity of PCB designs, all of which can affect precision.

Conclusion

Achieving precision in UAV PCB assembly is a multifaceted process that requires careful consideration of design, materials, manufacturing techniques, and quality control. By implementing advanced technologies and adhering to best practices, manufacturers can enhance the reliability and performance of UAVs. As the industry continues to evolve, staying informed about emerging trends and innovations will allow for continual improvement in UAV PCB assembly, ultimately leading to safer and more effective UAV operations.

Related news