Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

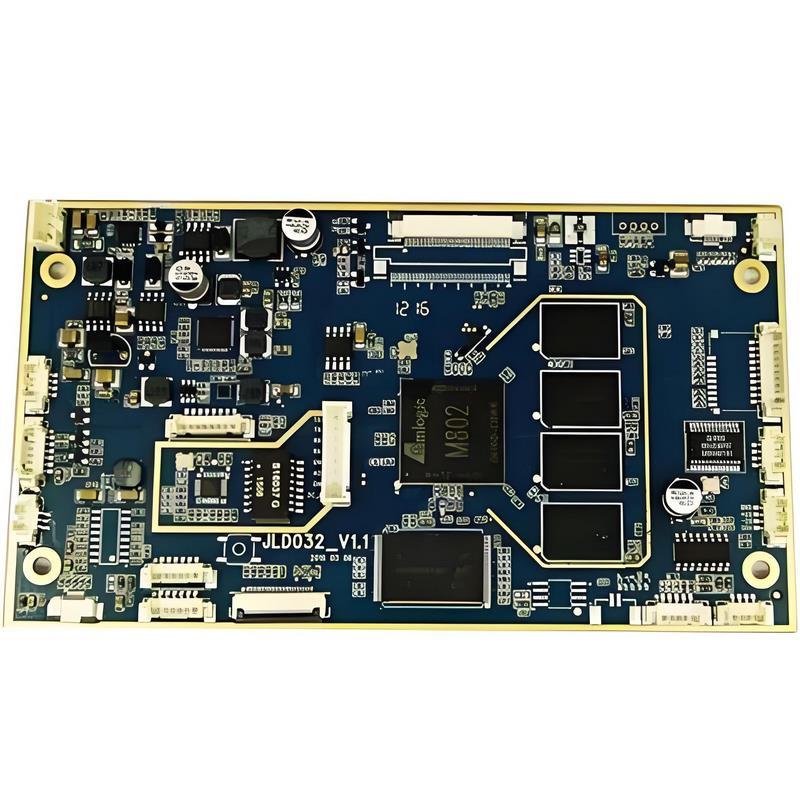

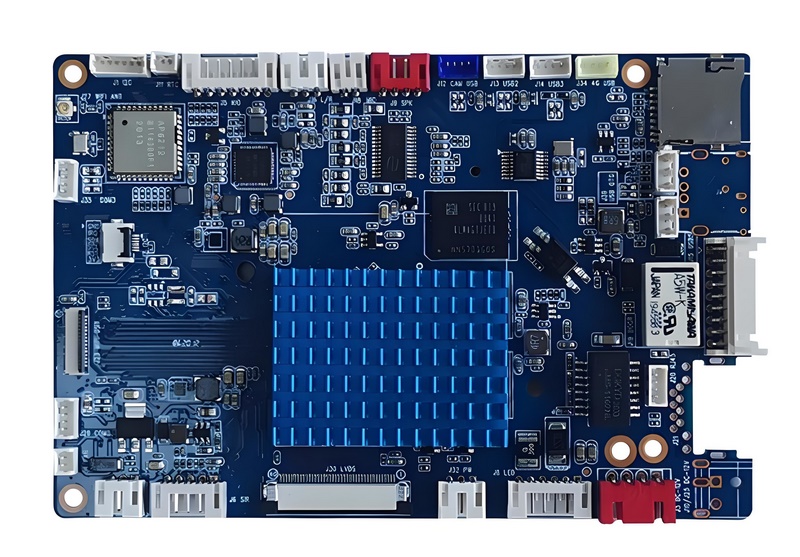

Facial Recognition PCB Assembly

One-stop PCBA/EMS Intelligent Manufacturing Solution

Facial Recognition PCB Assembly

The Role of PCBs in Facial Recognition

Printed Circuit Boards (PCBs) serve as the central backbone of facial recognition systems, enabling the integration of multiple high-performance components into a compact, reliable platform. They provide the electrical pathways that connect image sensors, microprocessors, memory modules, and communication interfaces, ensuring seamless data capture, processing, and transmission.

In facial recognition applications, PCBs must support high-speed data processing to handle complex algorithms, image enhancement, and machine learning tasks. They are also designed to accommodate specialized modules such as infrared (IR) sensors for low-light environments, high-definition cameras, and AI accelerators. Additionally, PCBs in these systems require robust EMI shielding, heat dissipation features, and durability to ensure consistent performance in various environmental conditions.

By enabling precise component integration and efficient signal management, PCBs make facial recognition systems faster, more accurate, and more reliable—supporting applications from security and access control to consumer electronics and smart city infrastructure.

Key Components of Facial Recognition PCB Assembly

1,Image Sensors

Capture high-resolution images or video for facial feature detection.

May include RGB sensors for color capture and infrared (IR) sensors for low-light or night vision capability.

2,Camera Module

Integrates the lens, image sensor, and related circuitry.

Ensures optimal image clarity and minimal distortion for accurate recognition.

3,AI/ML Processor (Neural Processing Unit or GPU)

Executes complex facial recognition algorithms and deep learning models.

Provides high-speed data analysis for real-time processing.

4,Memory Modules (RAM & Flash Storage)

Store image data, trained AI models, and processing instructions.

Enable quick retrieval and smooth performance.

5,Microcontroller or Main Control Unit (MCU/MPU)

Coordinates communication between sensors, processors, and external systems.

Handles device management, user interface, and system control logic.

6,Communication Interfaces

Includes USB, Ethernet, Wi-Fi, or Bluetooth modules for data transfer and system integration.

Allows connection to servers, cloud platforms, or IoT networks.

7,Power Management Circuitry

Regulates and distributes power to all components efficiently.

Includes voltage regulators, battery management, and protection circuits.

8,Thermal Management Solutions

Heat sinks, thermal pads, or copper pours to dissipate heat from high-performance chips.

Maintains stable operating conditions for sensitive components.

9,EMI/EMC Shielding

Prevents interference from external electromagnetic sources.

Ensures signal integrity and compliance with safety standards.

10,Connectors and Interfaces

Flexible flat cables (FFC), board-to-board connectors, and sensor sockets for modular design.

Facilitate easy assembly, maintenance, and upgrades.

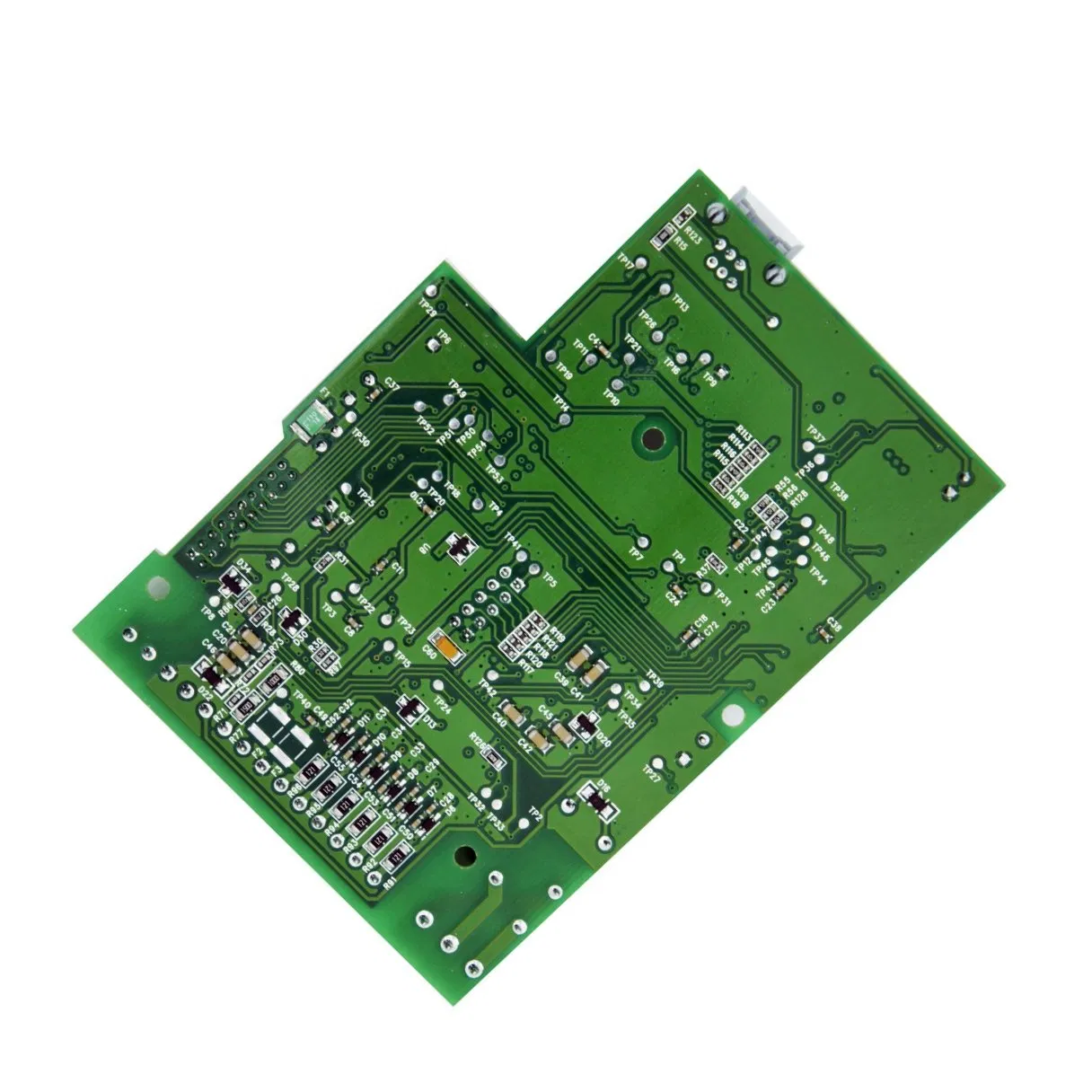

Materials and Technologies for Facial Recognition PCB Assembly

Facial recognition systems require PCBs that are both high-performance and extremely reliable, as they handle sensitive biometric data and operate in real time. The selection of materials and manufacturing technologies plays a critical role in ensuring precision, speed, and stability.

1. Core PCB Materials

High-TG FR4 – Provides enhanced heat resistance for boards handling high-speed signal processing.

Low-loss laminates – Such as Rogers or Isola materials, to maintain signal integrity for high-frequency image data transmission.

Copper Foil – High-purity copper for stable electrical conductivity and minimal resistance loss.

Solder Mask and Silkscreen – Protects circuitry from oxidation and aids in component identification.

2. Surface Finishing Technologies

ENIG (Electroless Nickel Immersion Gold) – Offers excellent oxidation resistance, fine pitch capability, and long shelf life.

OSP (Organic Solderability Preservatives) – Cost-effective and environmentally friendly for simpler designs.

Immersion Silver or Tin – Ensures smooth solderability and good signal performance.

3. Advanced Manufacturing Technologies

HDI (High-Density Interconnect) – Supports compact layouts for facial recognition modules with multiple sensors and processors.

Blind and Buried Vias – Reduces signal path lengths and improves high-speed data handling.

LDI (Laser Direct Imaging) – Enables ultra-precise circuit patterning for fine-pitch components.

Automated Optical Inspection (AOI) – Ensures accuracy during production by detecting microscopic defects.

4. Specialized Component Integration

BGA and CSP Packages – For high-speed processors and AI chips used in image recognition.

Shielding Layers – Minimizes electromagnetic interference for stable image processing.

5. Thermal and Signal Management

Thermal Vias and Heat Sinks – Disperse heat generated by image processors and LED illuminators.

Controlled Impedance Traces – Maintains data integrity for high-frequency camera signals.

In short, the choice of materials and technologies in facial recognition PCB assembly directly impacts system speed, image accuracy, and long-term reliability.

Facial Recognition PCB Assembly Process

The assembly of PCBs for facial recognition systems demands precision, reliability, and adherence to strict performance requirements. The process typically includes the following stages:

1,Design and Layout Preparation

Development of PCB schematics and layout optimized for high-speed data processing and integration with advanced sensors and cameras.

Incorporation of power distribution, signal integrity, and EMI/EMC considerations to ensure accurate recognition.

2,Material Selection

Use of high-Tg laminates, low-loss substrates, and thermal-resistant materials to maintain performance in various environmental conditions.

Selection of specialized copper finishes to support fine-pitch components and prevent oxidation.

3,Component Procurement

Sourcing high-quality components such as image processors, AI accelerators, memory chips, and optical sensors from trusted suppliers.

Verification of component authenticity to prevent counterfeit risks.

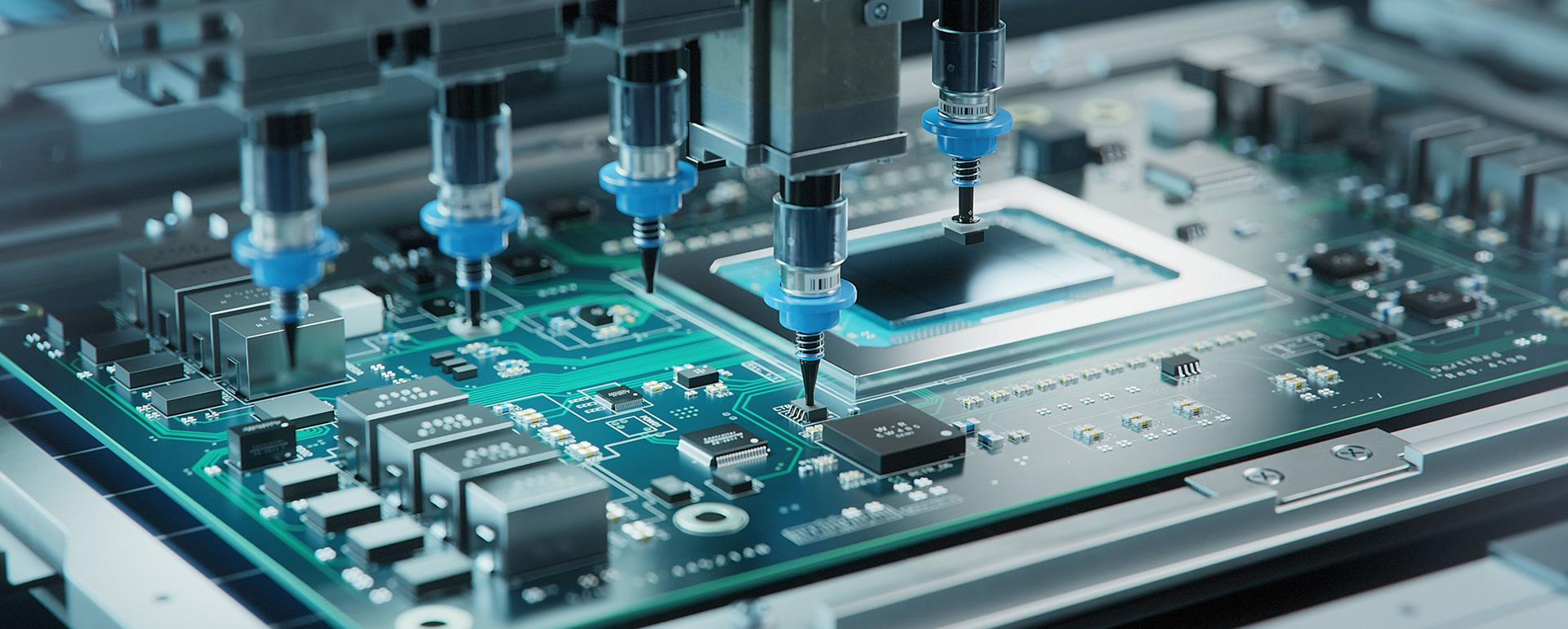

4,SMT (Surface Mount Technology) Assembly

Automated placement of microprocessors, memory modules, and interface ICs on the PCB using high-precision pick-and-place machines.

Application of solder paste using stencils for accurate pad coverage.

5,Reflow Soldering

Controlled heating process to ensure strong and reliable solder joints, especially for fine-pitch and BGA packages.

Profile optimization to prevent thermal stress on sensitive optical and processing components.

6,Inspection and Quality Control

Automated Optical Inspection (AOI) to detect misaligned or missing components.

X-ray inspection for hidden solder joints, particularly on BGAs and CSPs.

7,DIP and Through-Hole Assembly (if required)

Manual or automated insertion of connectors, larger capacitors, or other through-hole parts.

Wave soldering or selective soldering depending on the design requirements.

8,Functional Testing

FCT (Functional Circuit Test) to ensure signal integrity and proper communication between components.

Calibration of sensors and verification of image processing performance.

9,Final Assembly and Integration

Installation into the facial recognition system’s housing.

Environmental testing to confirm durability under varying temperature, humidity, and lighting conditions.

10,Packaging and Delivery

Secure packaging to prevent ESD damage during transportation.

Shipment to integrators or OEMs for system deployment.

Future Implications of Facial Recognition PCB Assembly

As facial recognition technology advances rapidly, the demands on PCB assembly are evolving to meet higher performance, security, and integration standards. Key future trends and implications include:

1. Increased Integration of AI and Edge Computing

On-board AI accelerators and neural processing units (NPUs) will become more prevalent, requiring PCBs capable of supporting high-speed data throughput and intensive computation.

This will reduce latency and increase real-time processing capabilities, enabling more autonomous and intelligent facial recognition systems.

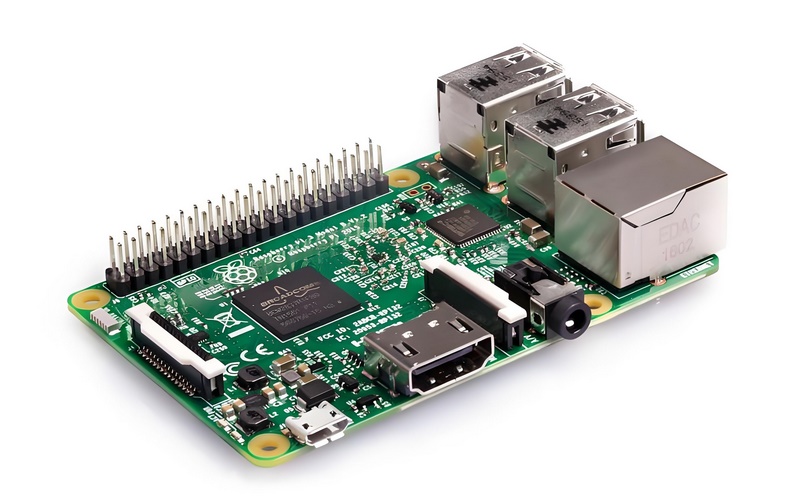

2. Miniaturization and Flexible Designs

PCBs will continue to shrink in size while increasing in complexity, allowing facial recognition modules to be embedded in smaller devices such as wearables, smart glasses, and mobile phones.

Flexible and rigid-flex PCBs will support new form factors and ergonomics without compromising signal integrity.

3. Enhanced Security Features

Future PCBs will incorporate advanced hardware security modules (HSM) and tamper-proof designs to safeguard biometric data and prevent hacking.

Improved EMI shielding and secure communication protocols at the hardware level will protect sensitive information.

4. Advanced Materials and Manufacturing Technologies

Adoption of next-generation substrates and coatings that offer better thermal management, durability, and signal fidelity.

Utilization of Industry 4.0 practices, including AI-driven quality control and real-time manufacturing analytics, to improve yield and reliability.

5. Sustainability and Eco-Friendly Manufacturing

Increased focus on environmentally responsible materials and lead-free, low-waste production processes.

Development of recyclable PCB materials aligned with global sustainability goals.

6. Multi-Modal Sensor Integration

PCBs will support integration of multiple sensing technologies (e.g., infrared, 3D depth sensors, LiDAR) to improve accuracy and robustness of facial recognition in diverse conditions.

Conclusion

PCBs are the critical foundation of facial recognition systems, enabling the integration of advanced sensors, high-speed processors, and communication interfaces into compact, reliable platforms. As facial recognition technology evolves, so too must PCB assembly methods—adopting miniaturization, enhanced security, and advanced materials to meet growing demands for accuracy, speed, and data protection.

By embracing cutting-edge manufacturing technologies and innovative designs, PCB manufacturers will play a pivotal role in advancing facial recognition solutions across security, consumer electronics, healthcare, and smart environments.

Ready to Elevate Your PCB Projects to New Heights?

In the fast-evolving world of facial recognition technology, precision, speed, and security are paramount. Our advanced PCB assembly expertise ensures your designs meet the highest standards for performance and reliability. From innovative materials to meticulous quality control, we empower you to deliver cutting-edge facial recognition solutions that stand out.

Partner with us to bring your vision to life with expertly crafted PCBs engineered for the demands of tomorrow’s biometric technologies.