Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

Medical Electronics PCB Assembly

One-stop PCBA/EMS Intelligent Manufacturing Solution

Medical Electronics PCB Assembly

Introduction

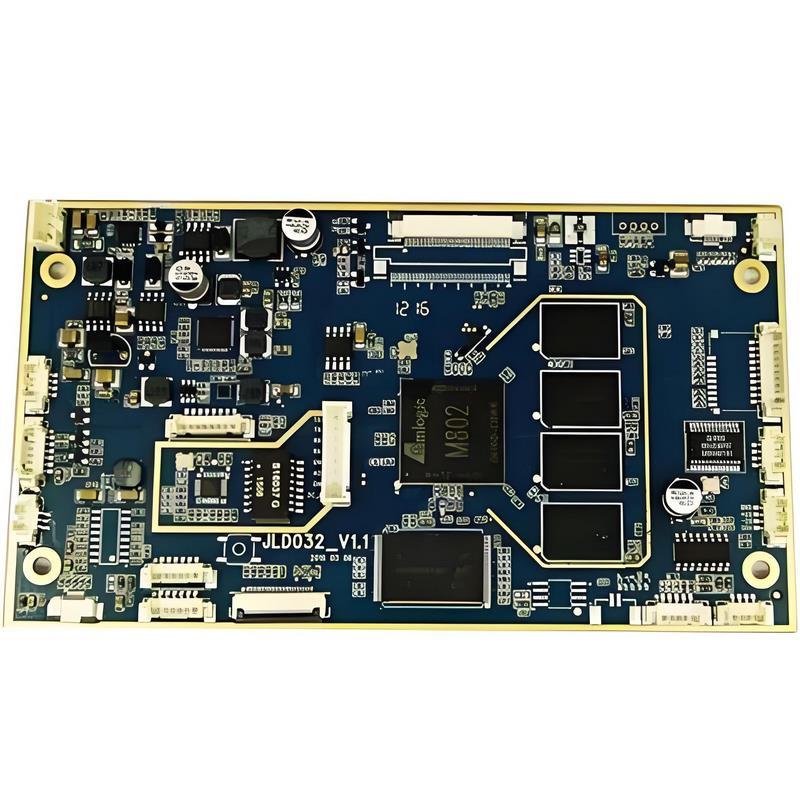

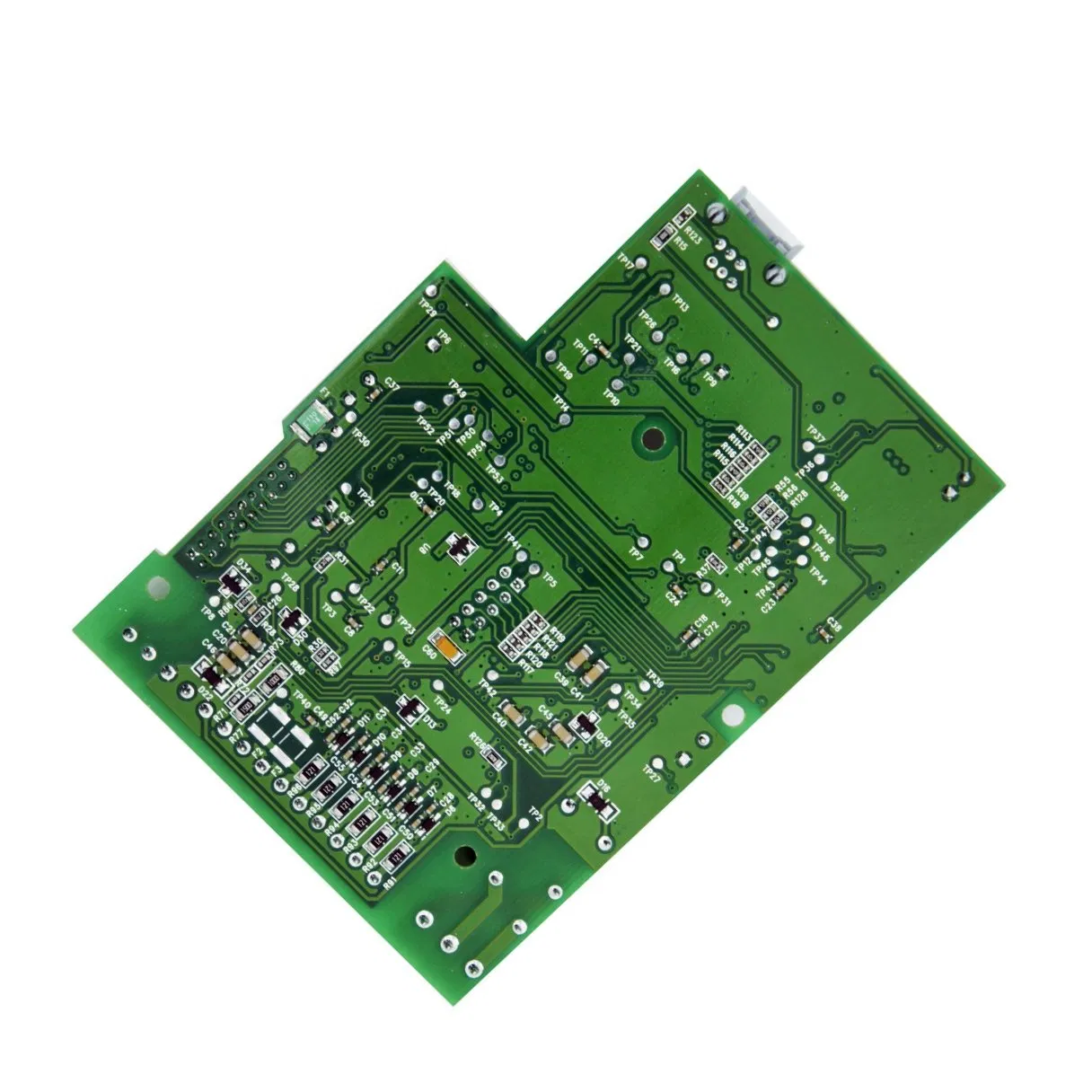

Medical electronics PCB assembly refers to the specialized process of designing, assembling, and testing printed circuit boards used in medical devices and healthcare systems. These PCBs serve as the electronic backbone of equipment ranging from portable diagnostic tools to life-critical systems such as defibrillators, patient monitors, MRI machines, and implantable devices.

Because human health and safety are directly involved, medical PCB assemblies must adhere to the highest levels of precision, reliability, and regulatory compliance. This requires:

Use of biocompatible and medical-grade components

Strict adherence to standards like ISO 13485, IPC Class III, and FDA 21 CFR Part 820

Rigorous testing, traceability, and documentation

Medical PCBs are often built with multi-layer, high-density, and miniaturized designs, supporting functions such as real-time data processing, wireless communication, and sensor integration. They are essential for enabling advanced diagnostics, remote monitoring, robotic surgery, and next-generation medical technologies.

Importance of PCBs in Medical Electronics

Printed Circuit Boards (PCBs) are at the core of nearly all modern medical devices, playing a critical role in enabling precise diagnostics, real-time monitoring, and life-saving treatments. Their importance lies in the following key areas:

1. Core Component of Life-Critical Devices

PCBs form the functional foundation of equipment such as:

ECG/EKG monitors

Defibrillators

Infusion pumps

Imaging systems (CT, MRI, X-ray)

Portable diagnostic devices

Surgical instruments and implants

These systems rely on stable and uninterrupted PCB performance to ensure patient safety and accurate operation.

2. Miniaturization and Portability

Medical devices are becoming more compact and portable. PCBs enable:

High-density circuit integration in small form factors

Use in wearable and implantable devices

Lightweight, flexible design for homecare and point-of-care technologies

3. High Precision and Reliability

Medical electronics demand ultra-high reliability and zero-tolerance for failure, especially in critical care:

PCBs are designed and assembled under IPC Class III standards

Use of redundancy, fail-safe circuitry, and error-checking systems

4. Support for Advanced Functions

Modern PCBs integrate components for:

Data acquisition and signal processing

Wireless communication (Wi-Fi, Bluetooth, LoRa)

AI and IoT connectivity for remote diagnostics and monitoring

Sensor integration for patient vitals and real-time alerts

5. Regulatory and Quality Compliance

To be used in medical applications, PCBs must comply with:

ISO 13485 for medical device quality management

FDA regulations (21 CFR Part 820) for design controls

RoHS/REACH for environmental safety

In short, without reliable PCBs, medical electronics would not be able to deliver the performance, accuracy, and safety required in today’s healthcare environment.

Benefits of Medical Electronics PCB Assembly

Medical electronics PCB assembly delivers the foundation for precision, safety, and innovation in today’s healthcare technologies. The benefits span across patient care, device performance, and regulatory compliance.

1. High Reliability and Safety

Medical PCBs are built to IPC Class III standards, ensuring the highest level of performance for life-critical devices.

Minimized risk of failure during operation in surgical, monitoring, and therapeutic applications.

Integration of redundant circuits and fail-safe designs for enhanced patient safety.

2. Support for Miniaturization

Enables compact and lightweight designs essential for:

Wearable health monitors

Implantable devices

Portable diagnostic tools

Facilitates multi-layer, rigid-flex, and HDI (High Density Interconnect) configurations.

3. Advanced Functional Integration

Supports real-time data acquisition, signal processing, and wireless transmission.

Allows integration of biosensors, microcontrollers, RF modules, and AI-capable chips.

Ideal for IoT-enabled medical systems and remote patient monitoring (RPM).

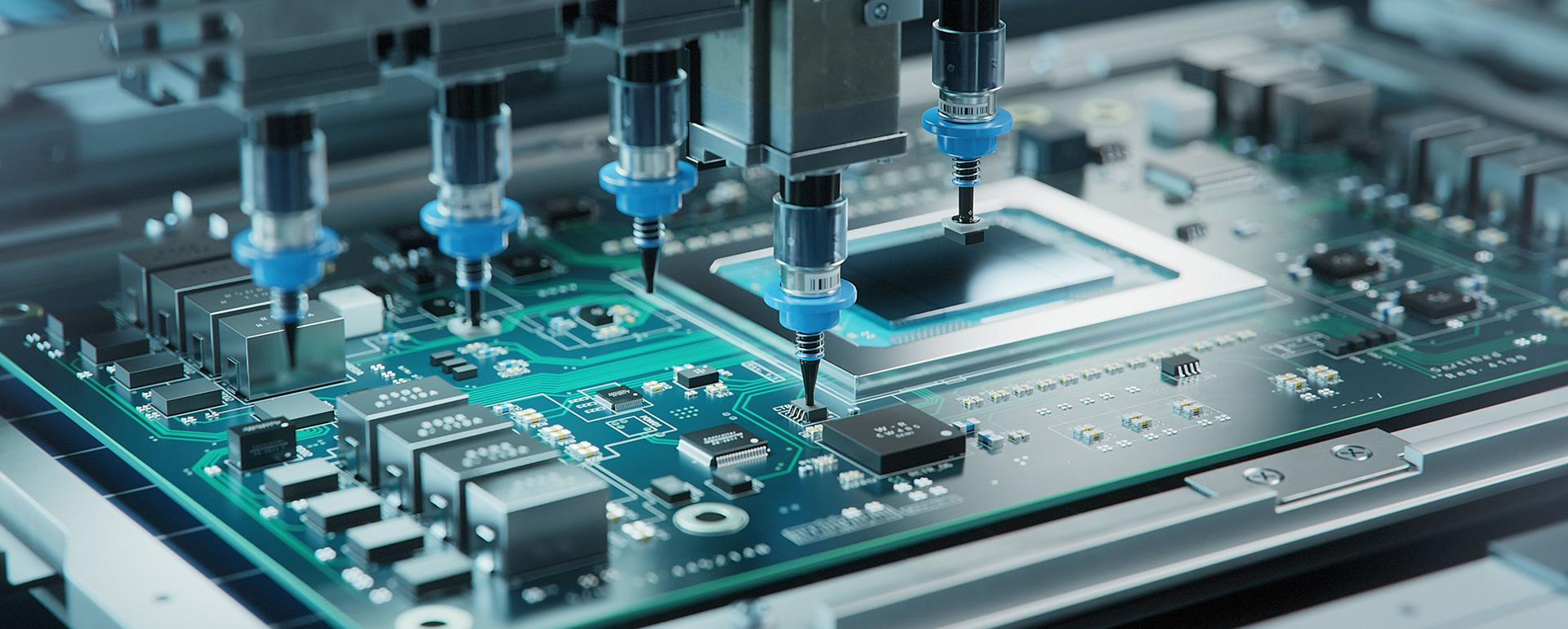

4. Strict Quality Assurance and Traceability

Assembled under cleanroom conditions with comprehensive testing (AOI, ICT, FCT).

Full component traceability, documentation, and lot control for regulatory audits.

Compliance with ISO 13485, FDA, RoHS, and UL standards.

5. Enhanced Patient Outcomes

Contributes to faster, more accurate diagnostics and improved treatment response.

Enables continuous monitoring and early detection of health risks.

Supports non-invasive, patient-friendly technologies.

6. Customization for Specialized Applications

Tailored PCB solutions for a wide range of medical fields:

Cardiology, neurology, radiology, emergency care, telemedicine, etc.

Flexible design options to meet unique form factors, power profiles, and biocompatibility needs.

Medical Electronics PCB Assembly is essential for advancing healthcare—delivering safe, smart, and scalable solutions for modern medical devices.

Challenges and Solutions in Medical Electronics PCB Assembly

The assembly of medical electronics PCBs presents unique challenges due to the life-critical nature, regulatory complexity, and miniaturization demands of medical devices. Addressing these challenges requires specialized knowledge, advanced technology, and rigorous process control.

1. Challenge: High Reliability and Zero Failure Tolerance

Issue:

Medical devices, especially life-support or surgical tools, must operate with near-zero failure rates. Even a single fault can pose a serious risk to patient safety.

Solution:

Follow IPC Class III standards for critical-use devices.

Use automotive/medical-grade components with extended life cycles.

Implement 100% AOI, X-ray, ICT, and FCT for thorough inspection and functional verification.

2. Challenge: Compliance with Stringent Medical Regulations

Issue:

Regulatory standards such as ISO 13485, FDA 21 CFR Part 820, and IEC 60601 require traceability, validation, and strict documentation.

Solution:

Establish a quality management system (QMS) that meets ISO 13485.

Maintain full component and process traceability.

Use validated manufacturing processes with documented DHR (Device History Records) and DHF (Device History Files).

3. Challenge: Miniaturization and Dense PCB Layouts

Issue:

Wearable, implantable, and handheld medical devices demand ultra-compact PCB designs with high component density, increasing risk of solder defects and layout constraints.

Solution:

Use HDI, microvia, and rigid-flex PCB designs.

Employ precision SMT machines for 01005 and BGA packages.

Utilize DFM and DFA analysis to optimize component placement and soldering quality.

4. Challenge: Thermal Management in Compact Designs

Issue:

Tightly packed electronics generate heat that may affect sensitive components or patient safety.

Solution:

Use high-Tg substrates, thermal vias, and metal-core PCBs (MCPCBs).

Integrate heat sinks or thermal interface materials (TIMs) in the design.

Perform thermal simulation during the design phase to predict hot spots.

5. Challenge: Biocompatibility and Patient Safety

Issue:

Some PCBs must be non-toxic, non-corrosive, and biocompatible, especially for contact or implantable devices.

Solution:

Choose biocompatible coatings (e.g., parylene) and materials.

Avoid harmful substances; ensure RoHS and REACH compliance.

Test materials for chemical resistance and long-term stability.

6. Challenge: Long Product Lifecycles and Component Obsolescence

Issue:

Medical devices often have 10–20 year lifespans, while components may be discontinued in a few years.

Solution:

Choose long-lifecycle or multi-source components.

Establish component lifecycle management and obsolescence strategies.

Collaborate with EMS providers offering supply chain continuity planning.

Medical electronics PCB assembly demands precision, quality, and accountability far beyond most other industries. By addressing challenges in reliability, regulatory compliance, thermal management, and design complexity, manufacturers can deliver safe, effective, and future-ready medical devices that improve lives and protect patients.

Conclusion

Medical electronics PCB assembly plays a crucial role in modern healthcare, forming the foundation for life-saving technologies, advanced diagnostics, and patient-centric innovations. Given the stringent reliability, safety, and regulatory demands, the design and assembly of medical PCBs require unmatched precision, process control, and industry expertise.

From wearable monitoring devices to complex imaging systems, success depends on high-quality PCB assembly that supports miniaturization, real-time data processing, wireless communication, and long-term reliability. By overcoming technical challenges and adhering to global standards such as ISO 13485, IPC Class III, and FDA 21 CFR, manufacturers can confidently deliver solutions that meet the evolving needs of healthcare professionals and patients alike.

As medical technology continues to evolve, investing in specialized PCB assembly ensures not just compliance—but also innovation, trust, and better health outcomes.

Ready to Elevate Your PCB Projects to New Heights?

When it comes to medical electronics, there’s no room for compromise. Whether you’re developing wearable diagnostics, surgical tools, imaging systems, or implantable devices, choosing the right PCB assembly partner is critical to achieving precision, reliability, and compliance.

We offer:

Expertise in medical-grade PCB design and assembly

Cleanroom assembly and advanced inspection systems (AOI, AXI, FCT)

Full traceability and ISO 13485/FDA-compliant processes

Custom solutions for low- and high-volume production runs

Let us help you bring your medical innovations to life with confidence and care.

Contact us today to discuss your project and explore how we can support your next breakthrough in healthcare technology.