Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

The Essentials of Rigid-Flex PCBs: A Comprehensive Guide for Professionals

2025-09-29

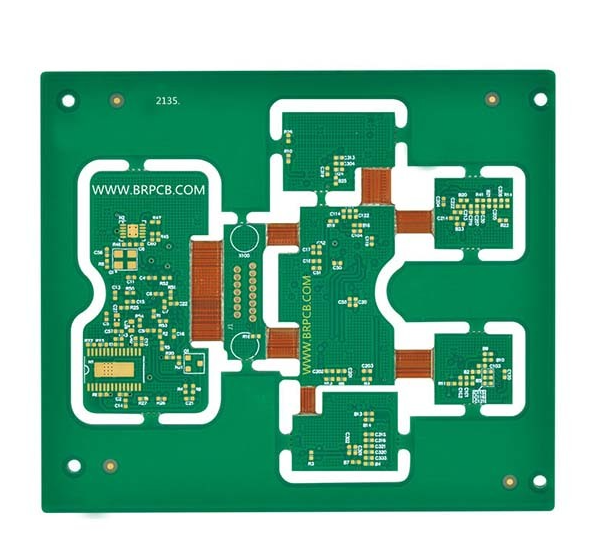

Rigid-Flex PCBs, or Rigid-Flexible Printed Circuit Boards, represent a unique integration of rigid and flexible circuit technologies, merging the stability of rigid boards with the adaptability of flexible circuits. This innovative approach has revolutionized the design and functionality of electronic devices, allowing for more compact and efficient solutions in a wide range of applications.

One of the most significant advantages of Rigid-Flex PCBs is their ability to save space and reduce weight. In many modern devices, such as smartphones, tablets, and medical equipment, space is at a premium. Rigid-Flex PCBs can be designed to conform to the specific geometries of the device, eliminating the need for multiple individual boards and interconnections. This not only simplifies assembly but also enhances the reliability and performance of the final product.

Additionally, Rigid-Flex PCBs offer exceptional durability. They can withstand the rigors of bending and twisting without compromising the integrity of the electrical connections. This is particularly advantageous in applications where the PCB must endure repeated flexing, such as in wearable technology or aerospace components. The combination of rigid and flexible segments allows for greater design freedom, enabling engineers to create complex circuits that meet the specific requirements of their projects.

Manufacturing Rigid-Flex PCBs involves a multi-layer process where layers of flexible and rigid materials are bonded together. This process requires precision and expertise to ensure the reliability of the final product. Advanced techniques such as controlled impedance and via-in-pad technology are often employed to ensure optimal electrical performance. As a result, these PCBs can support high-density interconnections and complex circuitry, catering to the needs of advanced electronic applications.

The applications of Rigid-Flex PCBs are vast and diverse. They are widely used in consumer electronics, automotive systems, medical devices, and telecommunications equipment. As the demand for miniaturization and increased functionality in electronic devices continues to grow, Rigid-Flex PCBs are becoming an increasingly popular choice among engineers and manufacturers.

In conclusion, Rigid-Flex PCBs offer a compelling combination of flexibility and rigidity, making them a valuable asset in modern electronics. Their ability to adapt to various applications while providing durability and space-saving solutions positions them at the forefront of PCB technology. For professionals in the electronic components industry, understanding the intricacies of Rigid-Flex PCB design and manufacturing is essential for staying competitive in this ever-evolving landscape.

One of the most significant advantages of Rigid-Flex PCBs is their ability to save space and reduce weight. In many modern devices, such as smartphones, tablets, and medical equipment, space is at a premium. Rigid-Flex PCBs can be designed to conform to the specific geometries of the device, eliminating the need for multiple individual boards and interconnections. This not only simplifies assembly but also enhances the reliability and performance of the final product.

Additionally, Rigid-Flex PCBs offer exceptional durability. They can withstand the rigors of bending and twisting without compromising the integrity of the electrical connections. This is particularly advantageous in applications where the PCB must endure repeated flexing, such as in wearable technology or aerospace components. The combination of rigid and flexible segments allows for greater design freedom, enabling engineers to create complex circuits that meet the specific requirements of their projects.

Manufacturing Rigid-Flex PCBs involves a multi-layer process where layers of flexible and rigid materials are bonded together. This process requires precision and expertise to ensure the reliability of the final product. Advanced techniques such as controlled impedance and via-in-pad technology are often employed to ensure optimal electrical performance. As a result, these PCBs can support high-density interconnections and complex circuitry, catering to the needs of advanced electronic applications.

The applications of Rigid-Flex PCBs are vast and diverse. They are widely used in consumer electronics, automotive systems, medical devices, and telecommunications equipment. As the demand for miniaturization and increased functionality in electronic devices continues to grow, Rigid-Flex PCBs are becoming an increasingly popular choice among engineers and manufacturers.

In conclusion, Rigid-Flex PCBs offer a compelling combination of flexibility and rigidity, making them a valuable asset in modern electronics. Their ability to adapt to various applications while providing durability and space-saving solutions positions them at the forefront of PCB technology. For professionals in the electronic components industry, understanding the intricacies of Rigid-Flex PCB design and manufacturing is essential for staying competitive in this ever-evolving landscape.

Related news