Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

Understanding Rigid-Flex PCBs: The Future of Electronic Connectivity

2025-09-12

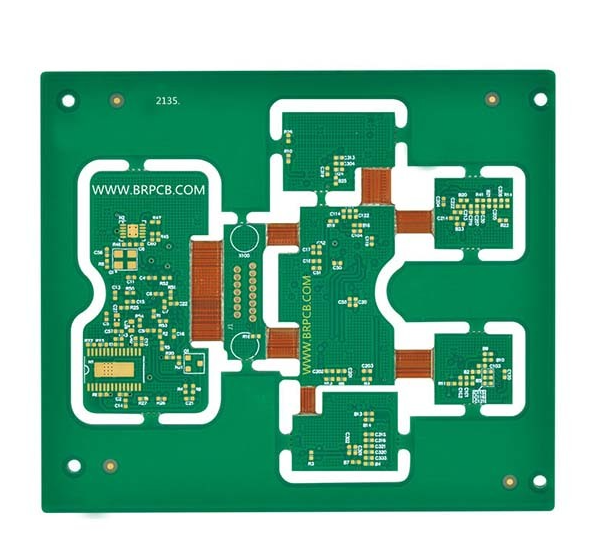

Rigid-flex PCBs, or rigid-flexible printed circuit boards, are innovative components that integrate both rigid and flexible circuit technologies into a single unit. This unique combination allows for increased versatility in design, making them an ideal choice for various electronic applications. Rigid-flex PCBs consist of multiple layers of circuits, where some layers are rigid while others are flexible. This structure provides several benefits, particularly in space-constrained environments.

One of the primary advantages of rigid-flex PCBs is their ability to reduce the overall size and weight of electronic devices. Traditional PCB designs often require multiple separate rigid and flexible circuits connected by connectors, which can increase both bulk and complexity. By using rigid-flex PCBs, manufacturers can eliminate the need for additional connectors and wiring, leading to a more compact design. This is particularly advantageous in industries such as aerospace, medical devices, and consumer electronics, where size and weight are critical factors.

Moreover, rigid-flex PCBs are renowned for their reliability and durability. The combination of rigid and flexible sections allows these boards to withstand mechanical stress and thermal fluctuations better than traditional designs. This enhanced resilience makes them suitable for harsh environments, such as military applications or extreme temperature conditions.

Another significant benefit is their ability to facilitate complex circuit designs. Rigid-flex PCBs can accommodate intricate layouts that would be challenging or even impossible to achieve with standard rigid or flexible PCBs alone. This capability allows engineers to innovate without being limited by design constraints, ultimately leading to more advanced and efficient electronic products.

Additionally, the manufacturing processes for rigid-flex PCBs have advanced significantly in recent years. Innovations in materials and techniques have made them more accessible to a broader range of applications. As a result, many electronics manufacturers are now considering rigid-flex PCBs as a viable option for new product developments.

In conclusion, rigid-flex PCBs represent a crucial advancement in the field of electronics. Their unique combination of rigidity and flexibility allows for compact designs, improved reliability, and the potential for complex circuit layouts. As industries continue to evolve and demand more sophisticated electronic solutions, rigid-flex PCBs are likely to play an increasingly vital role in shaping the future of electronic connectivity. Understanding their features and advantages can help stakeholders make informed decisions about incorporating them into their products.

One of the primary advantages of rigid-flex PCBs is their ability to reduce the overall size and weight of electronic devices. Traditional PCB designs often require multiple separate rigid and flexible circuits connected by connectors, which can increase both bulk and complexity. By using rigid-flex PCBs, manufacturers can eliminate the need for additional connectors and wiring, leading to a more compact design. This is particularly advantageous in industries such as aerospace, medical devices, and consumer electronics, where size and weight are critical factors.

Moreover, rigid-flex PCBs are renowned for their reliability and durability. The combination of rigid and flexible sections allows these boards to withstand mechanical stress and thermal fluctuations better than traditional designs. This enhanced resilience makes them suitable for harsh environments, such as military applications or extreme temperature conditions.

Another significant benefit is their ability to facilitate complex circuit designs. Rigid-flex PCBs can accommodate intricate layouts that would be challenging or even impossible to achieve with standard rigid or flexible PCBs alone. This capability allows engineers to innovate without being limited by design constraints, ultimately leading to more advanced and efficient electronic products.

Additionally, the manufacturing processes for rigid-flex PCBs have advanced significantly in recent years. Innovations in materials and techniques have made them more accessible to a broader range of applications. As a result, many electronics manufacturers are now considering rigid-flex PCBs as a viable option for new product developments.

In conclusion, rigid-flex PCBs represent a crucial advancement in the field of electronics. Their unique combination of rigidity and flexibility allows for compact designs, improved reliability, and the potential for complex circuit layouts. As industries continue to evolve and demand more sophisticated electronic solutions, rigid-flex PCBs are likely to play an increasingly vital role in shaping the future of electronic connectivity. Understanding their features and advantages can help stakeholders make informed decisions about incorporating them into their products.

Related news