Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

Understanding Elevator Control PCB Assembly: Key Insights for the Electronics Industry

2025-09-11

Elevator Control PCB Assembly is a crucial component in the functioning of modern elevator systems. This assembly plays a significant role in controlling the various operations within elevators, ensuring safety, efficiency, and reliability. Understanding the intricacies of this technology can be beneficial for professionals in the electronics sector, particularly those dealing with other electronic components.

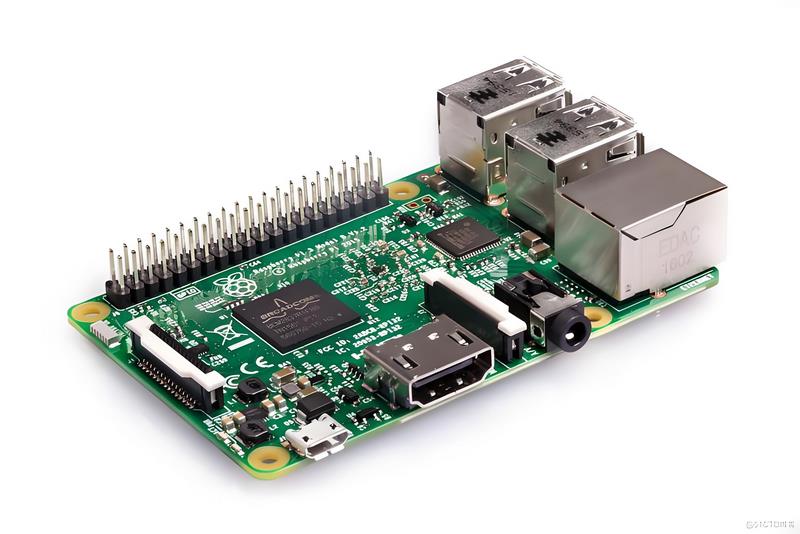

At the heart of Elevator Control PCB Assembly is the printed circuit board (PCB) itself, which serves as the platform for mounting various electronic components, such as microcontrollers, sensors, and power management devices. These components work together to execute commands, monitor elevator positions, and manage the overall functionality of the lift system. A well-designed PCB can significantly enhance the performance and reliability of elevators, making it a focal point in elevator technology.

One of the primary considerations in designing a PCB for elevator control is ensuring that it meets stringent safety standards. Elevators must operate reliably under various conditions, and any failure could lead to serious safety hazards. Therefore, the design phase must include careful selection of materials that can withstand environmental factors such as humidity, temperature fluctuations, and electrical interference. Additionally, the layout of the PCB should facilitate efficient heat dissipation and minimize electromagnetic interference, which could disrupt the elevator’s operation.

Another important aspect of Elevator Control PCB Assembly is the integration of advanced components such as programmable logic controllers (PLCs) and digital signal processors (DSPs). These components enable sophisticated algorithms to control elevator movements, enhance energy efficiency, and provide real-time diagnostics. For instance, using sensors to monitor the load in an elevator can optimize energy consumption by adjusting the motor's power based on current usage.

Manufacturers involved in Elevator Control PCB Assembly must also consider the assembly process itself, which encompasses soldering techniques, component placement, and quality assurance. Automated assembly processes, such as surface mount technology (SMT), have become increasingly prevalent, allowing for greater precision, reduced labor costs, and faster production times. However, quality control remains paramount, as any flaws in the assembly can lead to malfunctions that compromise safety.

Furthermore, as the elevator industry moves towards greater automation and smart technology integration, the role of Elevator Control PCB Assembly will continue to evolve. Incorporating IoT (Internet of Things) capabilities into PCB designs allows for remote monitoring and predictive maintenance, which can greatly enhance operational efficiency and user experience.

In summary, Elevator Control PCB Assembly is a complex but essential process that underpins the functionality and safety of modern elevators. By focusing on design considerations, safety standards, and advancements in technology, professionals in the electronics industry can ensure that they are well-equipped to meet the challenges and demands of this vital sector.

At the heart of Elevator Control PCB Assembly is the printed circuit board (PCB) itself, which serves as the platform for mounting various electronic components, such as microcontrollers, sensors, and power management devices. These components work together to execute commands, monitor elevator positions, and manage the overall functionality of the lift system. A well-designed PCB can significantly enhance the performance and reliability of elevators, making it a focal point in elevator technology.

One of the primary considerations in designing a PCB for elevator control is ensuring that it meets stringent safety standards. Elevators must operate reliably under various conditions, and any failure could lead to serious safety hazards. Therefore, the design phase must include careful selection of materials that can withstand environmental factors such as humidity, temperature fluctuations, and electrical interference. Additionally, the layout of the PCB should facilitate efficient heat dissipation and minimize electromagnetic interference, which could disrupt the elevator’s operation.

Another important aspect of Elevator Control PCB Assembly is the integration of advanced components such as programmable logic controllers (PLCs) and digital signal processors (DSPs). These components enable sophisticated algorithms to control elevator movements, enhance energy efficiency, and provide real-time diagnostics. For instance, using sensors to monitor the load in an elevator can optimize energy consumption by adjusting the motor's power based on current usage.

Manufacturers involved in Elevator Control PCB Assembly must also consider the assembly process itself, which encompasses soldering techniques, component placement, and quality assurance. Automated assembly processes, such as surface mount technology (SMT), have become increasingly prevalent, allowing for greater precision, reduced labor costs, and faster production times. However, quality control remains paramount, as any flaws in the assembly can lead to malfunctions that compromise safety.

Furthermore, as the elevator industry moves towards greater automation and smart technology integration, the role of Elevator Control PCB Assembly will continue to evolve. Incorporating IoT (Internet of Things) capabilities into PCB designs allows for remote monitoring and predictive maintenance, which can greatly enhance operational efficiency and user experience.

In summary, Elevator Control PCB Assembly is a complex but essential process that underpins the functionality and safety of modern elevators. By focusing on design considerations, safety standards, and advancements in technology, professionals in the electronics industry can ensure that they are well-equipped to meet the challenges and demands of this vital sector.

Related news