Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

Why Communication is Key in AIoT PCB Assembly Processes

2025-09-16

Why Communication is Key in AIoT PCB Assembly Processes

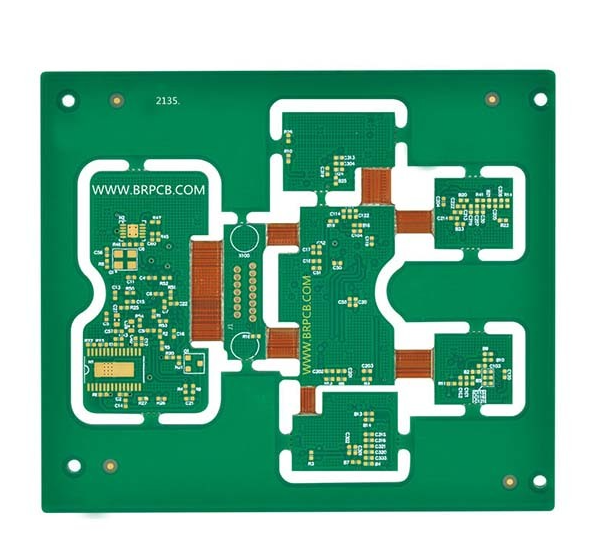

In the dynamic landscape of electronics, particularly in the realm of AIoT (Artificial Intelligence of Things), the assembly of printed circuit boards (PCBs) stands as a crucial process. The integration of AI into IoT devices necessitates not only advanced technology but also seamless collaboration among all stakeholders involved in PCB assembly. This article explores why communication is indispensable in AIoT PCB assembly processes and how it can ultimately determine the success of a project.

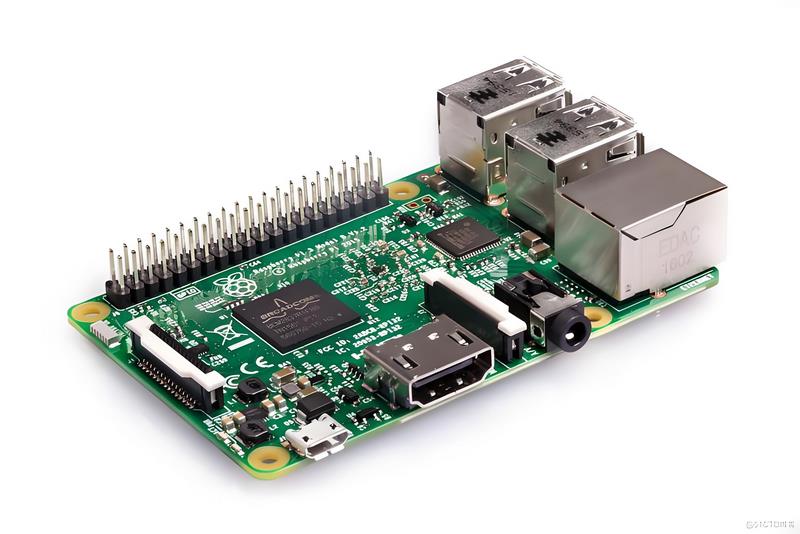

Understanding AIoT and Its Implications for PCB Assembly

The convergence of artificial intelligence and the Internet of Things has given rise to AIoT, a transformative technology that enhances the functionality and intelligence of connected devices. In PCB assembly, this integration presents unique challenges and opportunities. AIoT devices demand high precision, rapid production cycles, and a flexible approach to design and manufacturing. Effective communication among team members, suppliers, and clients is vital to navigate these complexities.

The Role of Effective Communication in PCB Assembly

Effective communication acts as the backbone of successful PCB assembly processes. It ensures that all parties are aligned on objectives, timelines, and quality standards. Here are several key aspects where communication plays a crucial role:

1. Reducing Errors and Misunderstandings

In PCB assembly, even minor errors can lead to significant issues down the line. Clear communication channels help in clarifying specifications, design changes, and assembly instructions, thereby minimizing the risk of misunderstandings that could result in costly mistakes.

2. Enhancing Collaboration Among Teams

AIoT projects often involve multidisciplinary teams including engineers, designers, and project managers. By fostering an environment of open communication, teams can collaborate more effectively, share insights, and leverage each other's expertise to enhance the overall quality of the assembly process.

3. Streamlining Workflow and Processes

Efficient communication facilitates the flow of information, enabling teams to respond promptly to challenges and changes in the production process. By streamlining workflows, companies can significantly reduce lead times and improve overall productivity.

4. Ensuring Compliance with Standards

AIoT devices must adhere to various industry standards and regulations. Continuous communication among all stakeholders ensures that everyone is aware of compliance requirements, leading to a smoother and more efficient assembly process.

Key Communication Strategies for Successful PCB Assembly

Implementing effective communication strategies is essential for optimizing the AIoT PCB assembly process. Here are some proven strategies to enhance communication:

1. Establish Clear Communication Channels

Identifying and establishing clear communication channels is crucial. Whether through project management software, regular meetings, or collaborative platforms, ensuring that information flows seamlessly among all parties will significantly enhance efficiency.

2. Utilize Advanced Technology for Communication

Incorporating advanced communication technologies, such as real-time messaging apps, video conferencing, and collaborative design tools, enables teams to stay connected regardless of geographical barriers. This technology enhances real-time communication and accelerates decision-making processes.

3. Foster a Culture of Openness

A culture that encourages open dialogue can lead to more innovative solutions. By promoting an environment where team members feel comfortable sharing ideas, feedback, and concerns, companies can enhance problem-solving capabilities and drive project success.

4. Implement Regular Feedback Loops

Establishing regular feedback loops among team members helps to identify potential issues early on. Conducting post-project reviews and continual performance assessments can enhance future communication strategies, ensuring ongoing improvement in the PCB assembly process.

5. Provide Comprehensive Training

Investing in training programs that focus on both technical skills and communication strategies will empower teams to work more effectively. Understanding how to communicate design specifications and assembly instructions clearly is crucial for success in AIoT PCB assembly.

Challenges to Effective Communication in AIoT PCB Assembly

While effective communication is vital, there are several challenges that can impede the process:

1. Geographical Dispersal of Teams

With teams often working in different locations, maintaining consistent communication can be challenging. Companies must leverage technology to bridge these gaps and ensure everyone is on the same page.

2. Technical Jargon and Complexity

The technical nature of PCB assembly can lead to misunderstandings if team members are not well-versed in specific jargon or concepts. Simplifying language and ensuring clarity in communication is essential to overcoming this barrier.

3. Time Constraints and Pressures

High-pressure environments may lead to rushed communications, increasing the likelihood of errors. Companies should prioritize effective communication even during busy times to uphold quality and efficiency.

4. Resistance to Change

Implementing new communication strategies may meet resistance from team members accustomed to traditional methods. Leading change initiatives that highlight the benefits of improved communication can help in garnering buy-in from all stakeholders.

Benefits of Effective Communication in AIoT PCB Assembly

Investing in effective communication strategies yields numerous benefits:

1. Increased Efficiency and Productivity

By minimizing misunderstandings and streamlining workflows, effective communication allows teams to focus on their tasks, leading to higher productivity levels.

2. Improved Quality of Products

With enhanced collaboration and clear specifications, the overall quality of AIoT devices improves, meeting customer expectations and industry standards.

3. Stronger Relationships with Stakeholders

Clear communication fosters trust and stronger relationships with suppliers, clients, and team members, which is crucial for long-term success.

4. Enhanced Innovation and Creativity

Open dialogue sparks creativity and innovation, leading to better designs and more efficient assembly processes, thereby keeping companies competitive in the market.

Real-World Examples of Effective Communication in AIoT PCB Assembly

Several leading companies have successfully implemented effective communication strategies in their AIoT PCB assembly processes:

1. Company A: Streamlined Processes through Technology

Company A utilized advanced project management tools to enhance communication across its global teams. By adopting a unified platform for sharing updates and feedback, the company drastically reduced assembly errors and improved turnaround times.

2. Company B: Cultivating a Culture of Openness

Company B fostered a culture that prioritizes open communication, encouraging team members to share ideas and concerns. This approach led to innovative design solutions and a more cohesive team dynamic.

Conclusion

Effective communication is undeniably the cornerstone of successful AIoT PCB assembly processes. By implementing strategies that promote clarity, collaboration, and continuous feedback, companies can navigate the complexities of this fast-paced industry with confidence. Emphasizing communication not only enhances efficiency and quality but also fosters innovation and strengthens relationships among all stakeholders. In the rapidly evolving world of AIoT, prioritizing communication will be the key to staying ahead of the competition and driving future success.

FAQs

1. What is AIoT, and how does it impact PCB assembly?

AIoT refers to the integration of artificial intelligence into the Internet of Things, enhancing the functionality and intelligence of connected devices. This impacts PCB assembly by requiring high precision and rapid production cycles, necessitating effective communication among all stakeholders.

2. Why is communication important in the PCB assembly process?

Communication is vital in PCB assembly to reduce errors, streamline workflows, enhance collaboration, and ensure compliance with industry standards, ultimately leading to higher quality products.

3. What are some effective communication strategies for PCB assembly?

Effective strategies include establishing clear communication channels, utilizing advanced technology, fostering a culture of openness, implementing regular feedback loops, and providing comprehensive training.

4. What challenges can arise in PCB assembly communication?

Challenges include geographical dispersal of teams, technical jargon, time constraints, and resistance to change. Overcoming these challenges is essential for maintaining effective communication.

5. How does effective communication influence innovation in AIoT PCB assembly?

Effective communication encourages open dialogue among team members, leading to increased creativity and innovation, which are crucial for developing better designs and improving assembly processes.

Related news