Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

Consumer Electronics PCB Assembly

One-stop PCBA/EMS Intelligent Manufacturing Solution

Consumer Electronics PCB Assembly

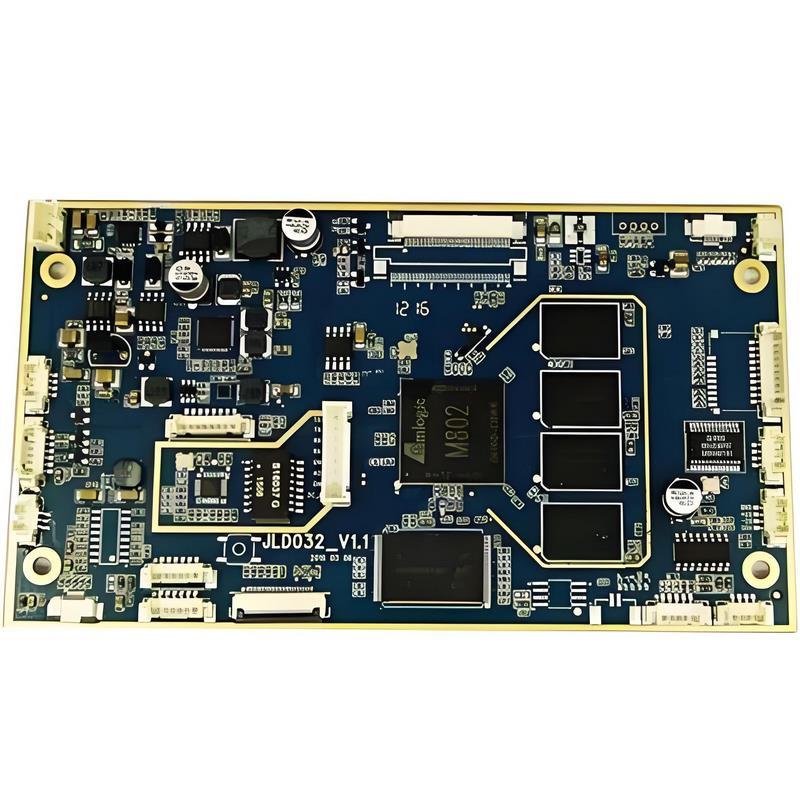

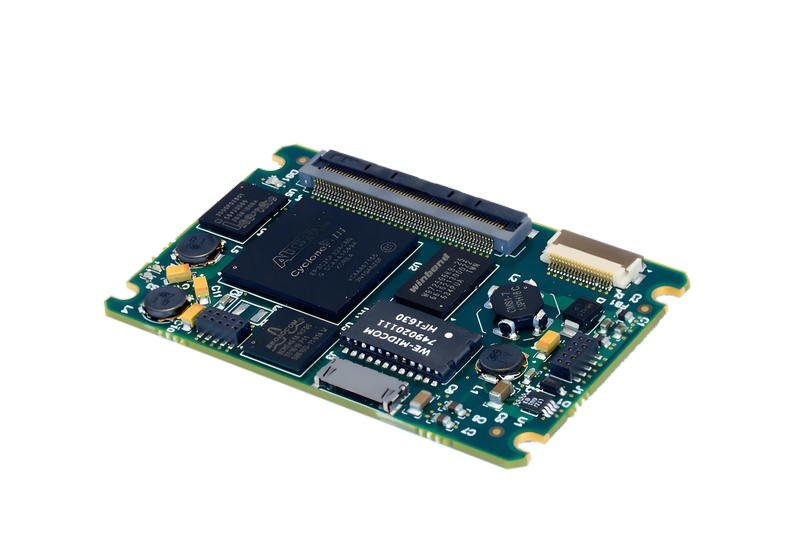

Key Components in Consumer Electronics PCB Assembly

Consumer electronics PCBs must be compact, efficient, and powerful — enabling seamless functionality across devices like smartphones, smartwatches, laptops, TVs, gaming consoles, and wearable tech. The following components are integral to their design and performance:

1. Microcontrollers (MCUs) / Microprocessors (MPUs)

Function: Central processing unit that executes commands and manages device functionality.

Used In: Smartphones, smartwatches, remote controls, fitness bands, etc.

2. Integrated Circuits (ICs)

Function: Perform complex tasks like signal processing, data conversion, and power management.

Types: Power ICs, audio/video ICs, memory ICs, interface ICs.

Used In: TVs, speakers, tablets, gaming devices.

3. Memory Components

Function: Store data, firmware, or user preferences.

Types: RAM, ROM, EEPROM, Flash Memory.

Used In: Phones, laptops, cameras, media players.

4. Passive Components

Function: Control voltage/current flow and signal timing.

Types: Resistors, capacitors, inductors.

Used In: All types of consumer electronics.

5. Sensors

Function: Detect motion, light, touch, proximity, temperature, or biometrics.

Types: Accelerometers, gyroscopes, ambient light sensors, fingerprint readers.

Used In: Smartphones, smartwatches, gaming controllers, AR/VR headsets.

6. Display Interfaces

Function: Drive and manage displays like LCD, OLED, or LED screens.

Components: Display drivers, connectors, backlight circuits.

Used In: TVs, tablets, smartwatches, cameras.

7. Power Management Units (PMUs)

Function: Regulate voltage levels, distribute power efficiently, manage battery charging.

Used In: Rechargeable devices such as phones, laptops, earbuds, etc.

8. Connectivity Modules

Function: Enable wireless communication and network access.

Types: Wi-Fi, Bluetooth, NFC, GPS, LTE/5G modules.

Used In: Smart home devices, wearables, wireless audio, mobile devices.

9. Audio Components

Function: Support sound output and input features.

Components: Amplifiers, DACs (digital-to-analog converters), microphones.

Used In: Smart speakers, headsets, TVs, phones.

10. Connectors and Ports

Function: Interface with external devices or power sources.

Types: USB, HDMI, headphone jack, charging port, SIM tray.

Used In: Virtually all consumer electronics.

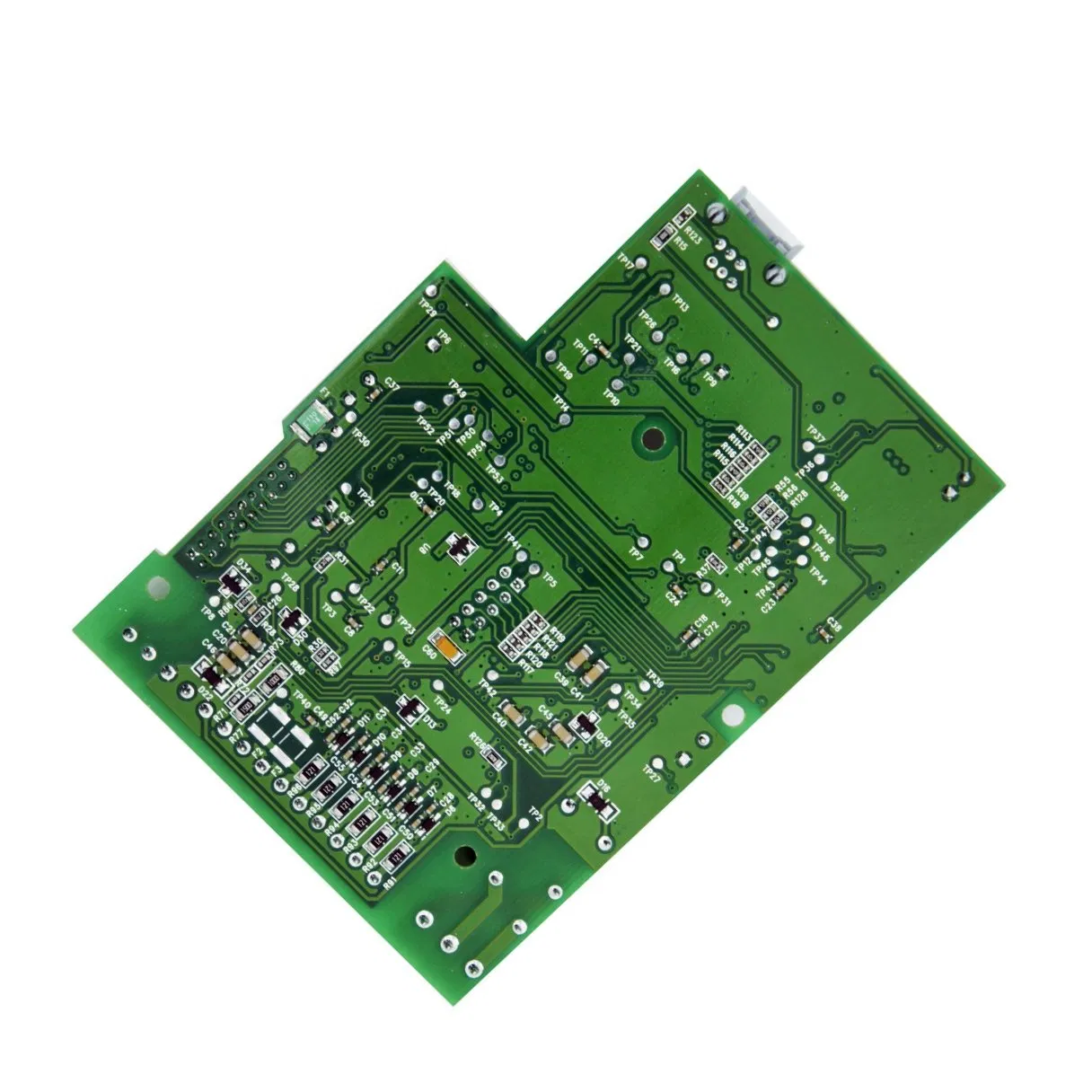

Consumer Electronics PCB Assembly Process

The PCB assembly process for consumer electronics demands precision, scalability, and speed — ensuring devices are compact, reliable, and high-performing. Below is a step-by-step overview of the typical assembly workflow:

1. Design & Engineering

Includes: PCB layout design, component selection, schematic capture, DFM (Design for Manufacturability) checks.

Purpose: Ensure the board is optimized for high performance, compact size, and low power consumption.

2. Procurement of Components

Includes: Sourcing verified, RoHS-compliant components from trusted suppliers.

Purpose: Ensure quality and compatibility while minimizing lead times and costs.

3. Stencil Preparation & Solder Paste Application

Includes: Creating a stainless-steel stencil and applying solder paste to the PCB pads.

Purpose: Prepares the board for precise SMT component placement.

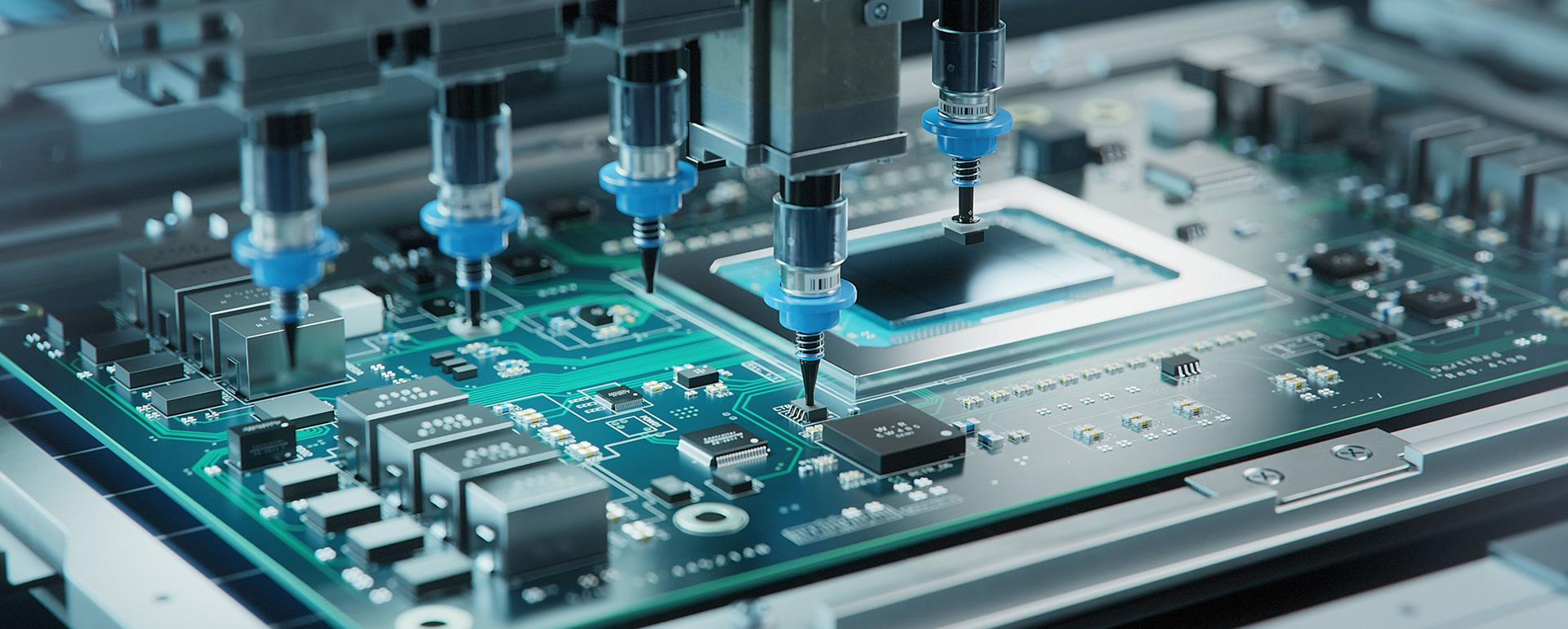

4. Surface Mount Technology (SMT) Assembly

Includes: High-speed pick-and-place machines place components like ICs, resistors, capacitors, and sensors onto the PCB.

Purpose: Enables accurate and efficient population of compact components.

5. Reflow Soldering

Includes: Boards pass through a controlled reflow oven to melt the solder paste and fix components in place.

Purpose: Achieves strong, electrically sound solder joints.

6. Through-Hole Component Insertion (if applicable)

Includes: Manual or automated insertion of larger components such as connectors, ports, or coils.

Purpose: Supports mechanical strength and power handling.

7. Wave Soldering or Selective Soldering (for through-hole)

Includes: Automated soldering of through-hole components.

Purpose: Ensures reliable connections for large or high-current components.

8. Automated Optical Inspection (AOI)

Includes: Camera-based system scans for soldering defects, misalignments, or missing parts.

Purpose: Maintains quality control and reduces rework.

9. X-ray Inspection (for BGA or hidden joints)

Includes: Non-destructive inspection of hidden solder joints.

Purpose: Verifies the integrity of complex, high-density components.

10. Functional & ICT Testing

Includes: In-Circuit Testing (ICT), Functional Circuit Test (FCT), and firmware flashing if required.

Purpose: Verifies the board functions as intended before integration into the final product.

11. Cleaning & Conformal Coating (optional)

Includes: Cleaning flux residues; applying protective coating for moisture, dust, or corrosion resistance.

Purpose: Extends product lifespan and ensures environmental protection.

12. Final Quality Control (QC) & Packaging

Includes: Final inspections, packaging in ESD-safe materials, labeling, and preparation for shipment.

Purpose: Ensures the product meets performance, safety, and compliance standards.

Benefits of Consumer Electronics PCB Assembly

With growing demand for smart, compact, and multifunctional devices, high-quality PCB assembly is essential to staying competitive in the consumer electronics industry. Here are the key benefits:

1. Compact and Lightweight Designs

Surface Mount Technology (SMT) enables high-density component placement.

Supports sleek, space-saving designs required for modern gadgets.

2. High-Speed, Reliable Performance

Precision assembly ensures consistent signal integrity and performance.

Critical for devices like smartphones, wearables, gaming consoles, and smart appliances.

3. Mass Production Scalability

Automated processes support high-volume production without compromising quality.

Fast turnaround times reduce time-to-market.

4. Cost Efficiency

Optimized component sourcing and automated assembly reduce labor and material costs.

Improves profitability while maintaining product competitiveness.

5. Customization and Flexibility

Easily adaptable to new design revisions and market demands.

Supports rapid prototyping and customization for different product lines.

6. Improved Product Reliability

Rigorous inspection (AOI, X-ray, functional testing) ensures durability and reduces failure rates.

Boosts brand reputation and user satisfaction.

7. Compliance with Global Standards

RoHS and ISO-certified assembly ensures environmental responsibility and regulatory compliance.

Opens access to global markets with stringent safety and quality requirements.

8. Faster Innovation Cycles

Integrated design and assembly streamline product development.

Ideal for brands that frequently launch updated models or product variations.

Applications and Use Cases

Consumer electronics PCBs are at the heart of virtually every modern smart device. Here's where and how they’re used:

🔋 Smartphones & Tablets

High-density, multi-layer PCBs for compact form factors

Support for wireless charging, 5G, Bluetooth, and camera integration

⌚ Wearable Devices

Flexible or rigid-flex PCBs in fitness trackers, smartwatches, and health monitors

Enable lightweight, low-power, and durable performance

🖥️ Smart TVs & Displays

PCBs for image processing, HDMI interfaces, power supply, and Wi-Fi modules

Ensure seamless media streaming and high-resolution performance

🎮 Gaming Consoles & Controllers

High-speed signal routing for GPUs and memory interfaces

PCBs used in handhelds, VR headsets, and wireless controllers

🧠 AI & Smart Assistants

Boards integrated with voice recognition, Wi-Fi, and cloud communication

Used in smart speakers, virtual assistants, and smart hubs

🏠 Home Appliances

PCBs power smart refrigerators, washing machines, ovens, air purifiers, etc.

Enable touchscreen control, IoT connectivity, and energy efficiency

📷 Cameras & Drones

Miniaturized PCBs for stabilization, image capture, GPS, and remote control

Essential for drones, DSLRs, action cams, and webcams

🖨️ Printers & Peripherals

PCBs control motors, displays, wireless modules, and data transfer

Used in inkjet/laser printers, scanners, and smart keyboards/mice

🎧 Audio & Multimedia Devices

Found in wireless headphones, speakers, and audio interfaces

Support for Bluetooth, noise cancellation, and smart voice integration

Conclusion

Consumer electronics demand precision, speed, and innovation — and high-quality PCB assembly is the foundation that powers it all.

From smartphones and wearables to smart home devices and entertainment systems, expertly assembled PCBs ensure the performance, reliability, and compact design today’s consumers expect.

Partnering with an experienced PCB assembly provider means more than just manufacturing — it means faster time-to-market, greater product stability, and scalable support for your next big idea.

Ready to Elevate Your PCB Projects to New Heights?

Whether you're developing next-gen consumer electronics or scaling production for smart devices, we’re here to bring your ideas to life — with speed, precision, and quality you can trust.

✅ End-to-End PCB Assembly Solutions

✅ Advanced Manufacturing Technologies

✅ Custom-Tailored Services for Every Stage

👉 Let’s build something extraordinary together.

Contact us today to get a quote or speak with our PCB experts.