Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

Why Precision Instruments Are Essential for High-Quality PCB Assembly

2025-09-26

Why Precision Instruments Are Essential for High-Quality PCB Assembly

Table of Contents

1. Introduction to PCB Assembly

2. The Importance of Precision in PCB Manufacturing

2.1 Understanding PCB Components and Their Functions

2.2 The Role of Tolerance in PCB Assembly

3. Types of Precision Instruments Used in PCB Assembly

3.1 Optical Inspection Systems

3.2 Automated Optical Inspection (AOI) Machines

3.3 Soldering and Assembly Tools

4. Benefits of Using Precision Instruments in PCB Assembly

4.1 Enhanced Accuracy and Quality Control

4.2 Increased Efficiency and Reduced Waste

4.3 Improved Reliability and Longevity of PCBs

5. Best Practices for Implementing Precision Instruments

5.1 Training and Skill Development

5.2 Regular Maintenance and Calibration

6. Case Studies: Success Stories in PCB Assembly

7. Frequently Asked Questions

8. Conclusion

1. Introduction to PCB Assembly

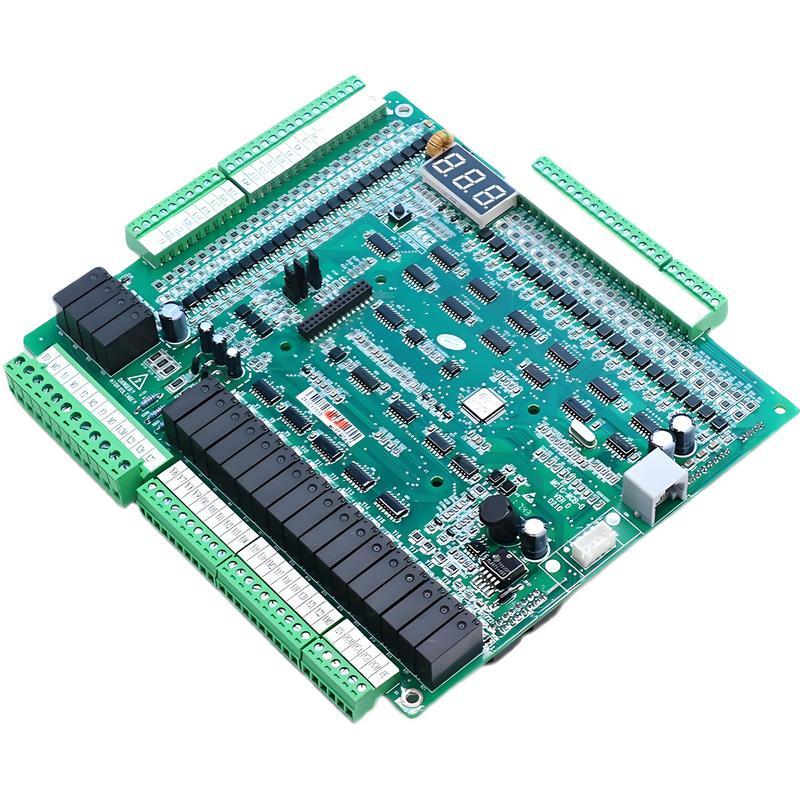

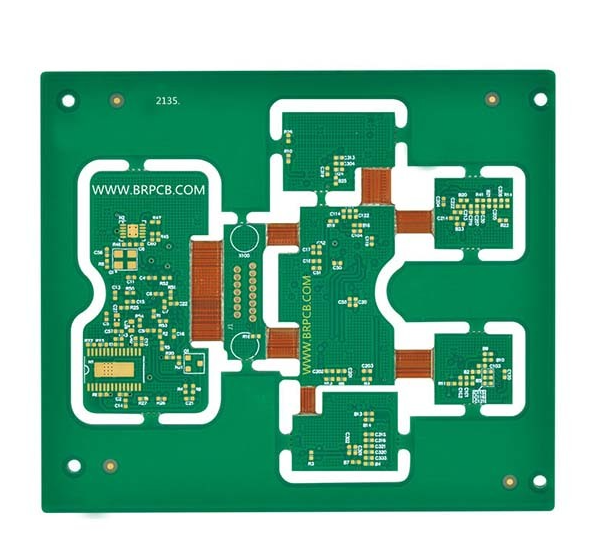

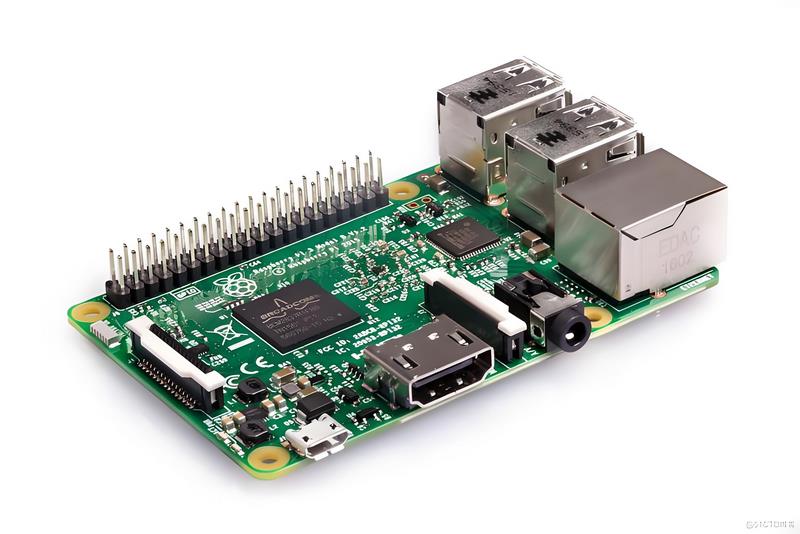

In today’s fast-paced electronic industry, **Printed Circuit Boards (PCBs)** serve as the backbone of virtually all electronic devices. The process of assembling these intricate components requires a meticulous approach, where precision instruments play a pivotal role. This article delves into why precision instruments are not merely beneficial but essential for achieving high-quality PCB assembly.

2. The Importance of Precision in PCB Manufacturing

The manufacturing of PCBs involves a variety of components that must be assembled with exactitude. **Precision** in this context refers to the meticulousness with which components are placed and soldered onto the board.

2.1 Understanding PCB Components and Their Functions

PCBs consist of various elements, including resistors, capacitors, and integrated circuits. Each component has a specific role, and the correct placement and connection of these parts are vital for the functionality of the entire circuit.

2.2 The Role of Tolerance in PCB Assembly

In PCB assembly, **tolerance** refers to the permissible limit or limits of variation in a physical dimension. High levels of precision ensure that components fit together correctly, which is essential for preventing malfunctions.

3. Types of Precision Instruments Used in PCB Assembly

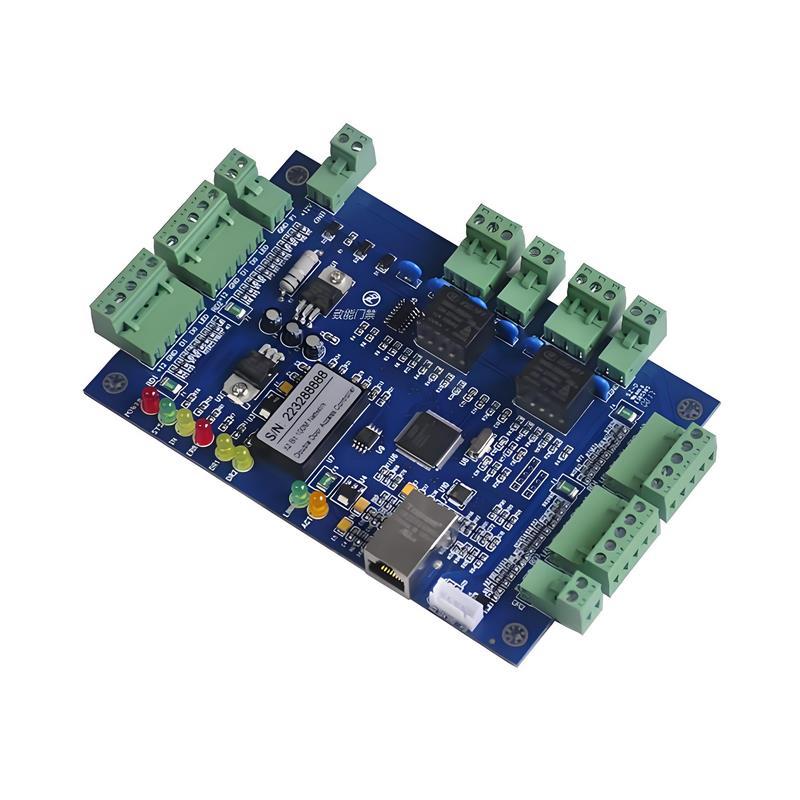

To ensure high-quality PCB assembly, several precision instruments are employed across different stages of the manufacturing process.

3.1 Optical Inspection Systems

Optical inspection systems are essential for visually assessing the integrity of PCBs. These instruments utilize cameras and advanced software to detect defects that the human eye might miss.

3.2 Automated Optical Inspection (AOI) Machines

AOI machines are a step further in enhancing inspection capabilities. They automate the inspection process, making it faster and more accurate by comparing the actual PCB layout against predefined schematics.

3.3 Soldering and Assembly Tools

Precision soldering tools, including soldering irons and automated soldering machines, ensure that components are securely attached to the PCB without damage.

4. Benefits of Using Precision Instruments in PCB Assembly

Incorporating precision instruments into PCB assembly offers a multitude of advantages that directly contribute to product quality.

4.1 Enhanced Accuracy and Quality Control

Precision instruments significantly boost the accuracy of component placements. This enhanced accuracy leads to better quality control and fewer errors during the manufacturing process.

4.2 Increased Efficiency and Reduced Waste

Automating certain processes with precision instruments can lead to higher efficiency, resulting in less waste of materials and time. This means that manufacturers can produce more with fewer resources.

4.3 Improved Reliability and Longevity of PCBs

When precision instruments are used to ensure the correct assembly of PCBs, the reliability of the final products improves. Well-assembled PCBs are less likely to fail, which enhances their lifespan in electronic devices.

5. Best Practices for Implementing Precision Instruments

To fully capitalize on the benefits of precision instruments, manufacturers should adhere to certain best practices.

5.1 Training and Skill Development

Investing in the training of staff operating precision instruments is crucial. Skilled operators can leverage the full capabilities of these tools, leading to improved outcomes in PCB assembly.

5.2 Regular Maintenance and Calibration

To maintain the accuracy and effectiveness of precision instruments, routine maintenance and calibration are essential. This ensures that these tools continue to function optimally and yield high-quality results.

6. Case Studies: Success Stories in PCB Assembly

Examining real-world applications can provide insights into how precision instruments lead to successful PCB assembly. Companies that have integrated advanced precision tools into their processes often report significant improvements in quality and efficiency.

7. Frequently Asked Questions

1. What are precision instruments in PCB assembly?

Precision instruments are tools and machines designed to ensure accurate component placement and soldering during PCB assembly.

2. Why is precision critical in PCB manufacturing?

Precision is vital for ensuring that components function correctly and reliably within the electronic devices they comprise, preventing failures and enhancing performance.

3. How do optical inspection systems work?

Optical inspection systems use cameras to capture images of PCBs, which are then analyzed using software to identify any defects.

4. What is the role of AOI machines in PCB assembly?

Automated Optical Inspection (AOI) machines automate the process of inspecting PCBs, allowing for faster and more accurate detection of defects compared to manual inspection methods.

5. How can manufacturers ensure the reliability of their PCBs?

Manufacturers can ensure PCB reliability by using precision instruments, implementing rigorous quality control processes, and investing in staff training.

8. Conclusion

In summary, precision instruments are not just beneficial but essential for high-quality PCB assembly. By ensuring accuracy, reducing waste, and improving the reliability of electronic components, these tools play a crucial role in modern electronics manufacturing. Embracing precision in PCB assembly processes helps manufacturers meet the ever-increasing demands for quality and efficiency in today's competitive market. Investing in precision instruments and best practices will undoubtedly lead to more robust, reliable, and high-performance electronic products.

Related news

Exploring the Future of AIoT PCB Assembly

2025-09-03