Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

Understanding Elevator Control PCB Assembly: Key Insights for Industry Professionals

2025-09-23

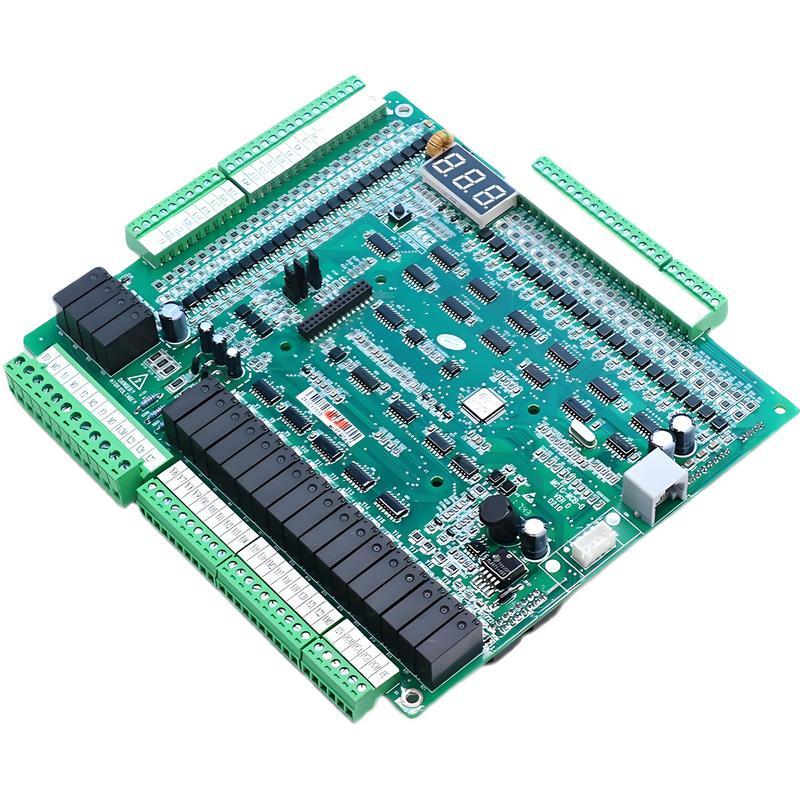

Elevator control systems are a vital part of modern architecture, ensuring safe and efficient transportation within buildings. At the heart of these systems lies the Elevator Control PCB (Printed Circuit Board), which plays a crucial role in the operational functionality of elevators. Understanding the intricacies of Elevator Control PCB Assembly is essential for professionals in the electronics industry, particularly those focusing on components and assembly processes.

Elevator Control PCB Assembly involves several key steps, starting with the design of the circuit board. Engineers utilize specialized software to create schematic diagrams that define the electrical pathways necessary for elevator operation. This process includes defining the microcontrollers, sensors, relays, and other components that will be mounted on the PCB. Proper circuit design is critical; it not only affects the performance but also the reliability and safety of the elevator system.

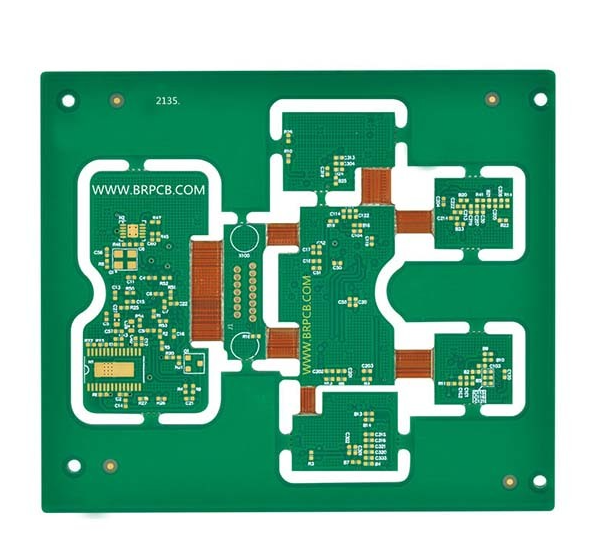

Once the design phase is complete, the next step is the fabrication of the PCB. This involves translating the design into a physical board through processes such as etching, drilling, and layering. Advanced techniques like surface mount technology (SMT) are often employed, allowing for smaller components to be placed precisely on the board, optimizing space and improving performance.

After fabrication, the assembly process begins. Components are soldered onto the PCB, and quality control measures are put in place to ensure that each unit meets industry standards. This includes functional testing, where the assembled PCB is subjected to various operational scenarios to verify that it performs as expected. Rigorous testing is crucial, as it helps identify any potential failures before the board is integrated into the elevator system.

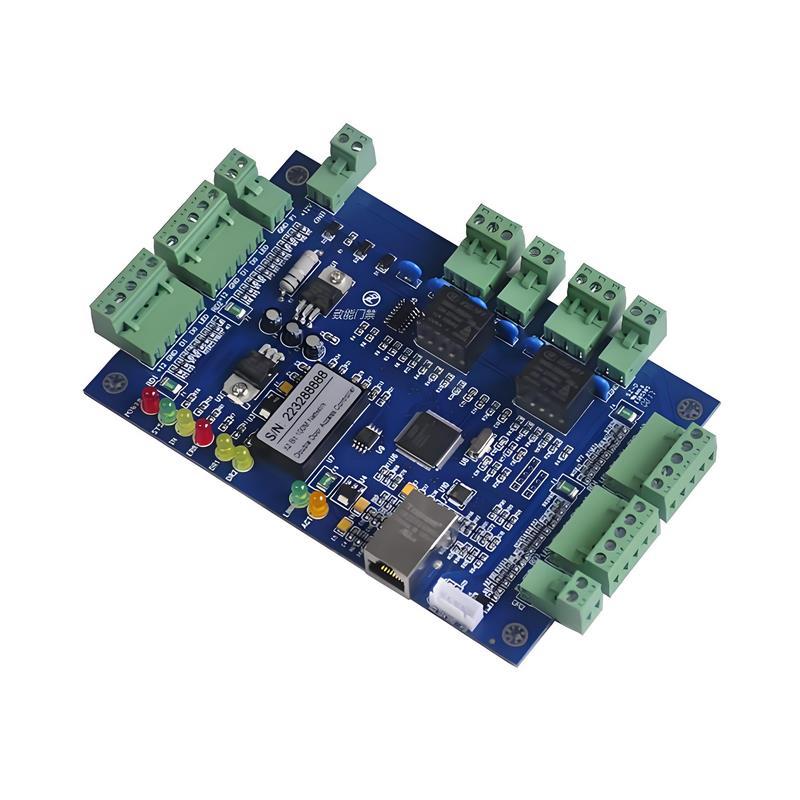

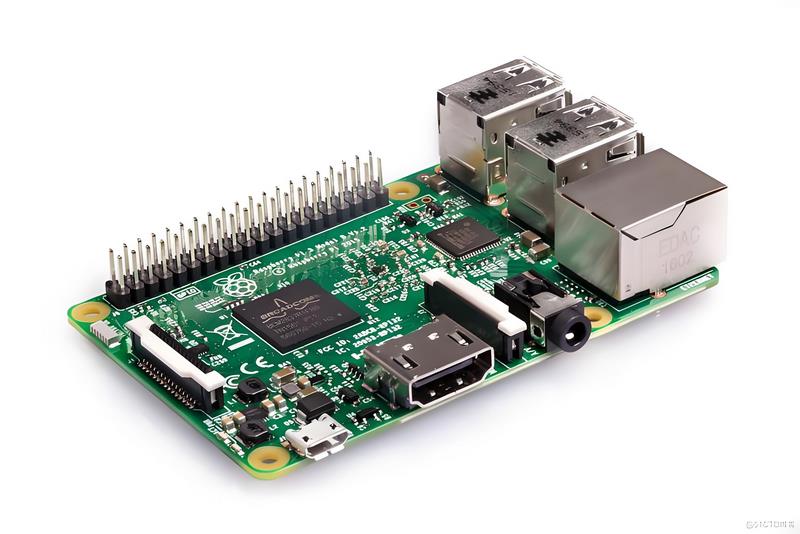

Moreover, the integration of modern technologies, such as IoT (Internet of Things) capabilities, is becoming increasingly common in Elevator Control PCB Assembly. This allows for enhanced monitoring and control, enabling features like predictive maintenance and remote diagnostics. Professionals in the field must stay informed about these advancements, as they can significantly impact the efficiency and safety of elevator systems.

In conclusion, Elevator Control PCB Assembly is a complex but fascinating area within the electronics industry. By understanding the design, fabrication, assembly, and testing processes involved, industry professionals can contribute to the development of safer and more efficient elevator systems. Embracing new technologies and methodologies will also ensure that they remain competitive in a rapidly evolving market. This knowledge is not only beneficial for those directly involved in PCB assembly but also for anyone engaged in the broader realm of electronic components and systems.

Elevator Control PCB Assembly involves several key steps, starting with the design of the circuit board. Engineers utilize specialized software to create schematic diagrams that define the electrical pathways necessary for elevator operation. This process includes defining the microcontrollers, sensors, relays, and other components that will be mounted on the PCB. Proper circuit design is critical; it not only affects the performance but also the reliability and safety of the elevator system.

Once the design phase is complete, the next step is the fabrication of the PCB. This involves translating the design into a physical board through processes such as etching, drilling, and layering. Advanced techniques like surface mount technology (SMT) are often employed, allowing for smaller components to be placed precisely on the board, optimizing space and improving performance.

After fabrication, the assembly process begins. Components are soldered onto the PCB, and quality control measures are put in place to ensure that each unit meets industry standards. This includes functional testing, where the assembled PCB is subjected to various operational scenarios to verify that it performs as expected. Rigorous testing is crucial, as it helps identify any potential failures before the board is integrated into the elevator system.

Moreover, the integration of modern technologies, such as IoT (Internet of Things) capabilities, is becoming increasingly common in Elevator Control PCB Assembly. This allows for enhanced monitoring and control, enabling features like predictive maintenance and remote diagnostics. Professionals in the field must stay informed about these advancements, as they can significantly impact the efficiency and safety of elevator systems.

In conclusion, Elevator Control PCB Assembly is a complex but fascinating area within the electronics industry. By understanding the design, fabrication, assembly, and testing processes involved, industry professionals can contribute to the development of safer and more efficient elevator systems. Embracing new technologies and methodologies will also ensure that they remain competitive in a rapidly evolving market. This knowledge is not only beneficial for those directly involved in PCB assembly but also for anyone engaged in the broader realm of electronic components and systems.

Related news

Exploring the Future of AIoT PCB Assembly

2025-09-03

2025-08-27