Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

The Future of Electronics: Innovations in Facial Recognition PCB Assembly

2025-09-20

The Future of Electronics: Innovations in Facial Recognition PCB Assembly

Table of Contents

- What is Facial Recognition PCB Assembly?

- The Importance of PCB Assembly in Facial Recognition Technology

- Key Innovations in Facial Recognition PCB Assembly

- Understanding the PCB Manufacturing Process

- Applications of Facial Recognition Technology

- Challenges in Facial Recognition PCB Assembly

- Future Trends in Facial Recognition Technology

- Conclusion

- FAQs

What is Facial Recognition PCB Assembly?

Facial recognition technology is a sophisticated system that identifies and verifies individuals by analyzing their facial features. At the core of this technology lies **Printed Circuit Board (PCB) assembly**, which integrates various electronic components to support the seamless operation of facial recognition systems. These systems rely on complex algorithms and hardware configurations, making PCB assembly a crucial element in their performance.

The Importance of PCB Assembly in Facial Recognition Technology

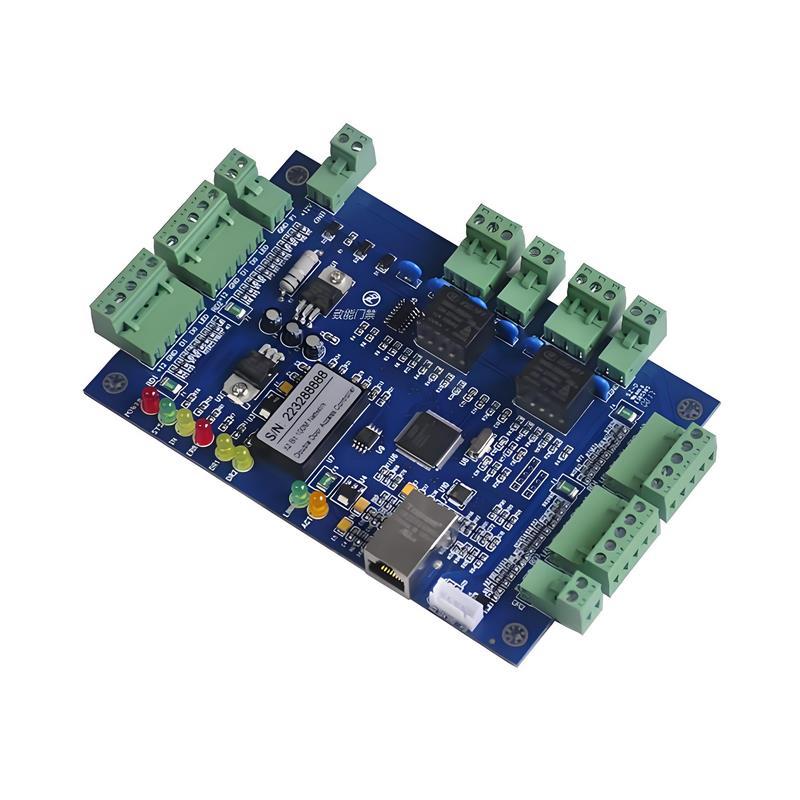

PCB assembly plays a significant role in enhancing the efficiency and accuracy of facial recognition technologies. The assembly involves the precise placement of components such as microcontrollers, sensors, and memory units, which collectively enable devices to capture, process, and analyze facial data. The efficiency of PCB assembly directly impacts the overall functionality of facial recognition systems, making it essential for manufacturers to prioritize quality and precision during the assembly process.

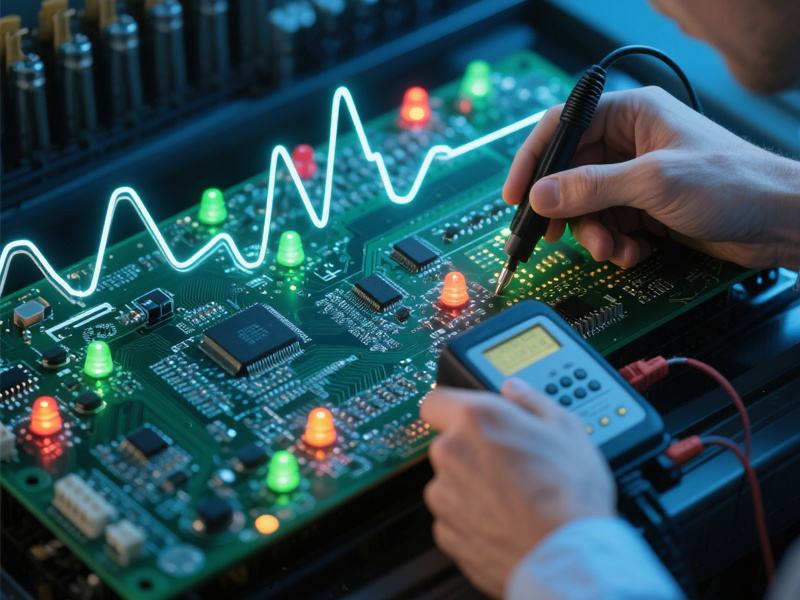

Reliability and Performance

The reliability of facial recognition systems hinges on the quality of the PCB assembly. High-quality assembly ensures that all components function harmoniously, reducing the likelihood of system failures and inaccuracies. Manufacturers invest in advanced assembly techniques to enhance the performance and durability of their products, thereby fostering consumer trust.

Cost Efficiency

Effective PCB assembly can significantly reduce production costs while maintaining quality. By optimizing the assembly process, manufacturers can minimize waste and enhance the scalability of their operations. This cost-effectiveness not only benefits the manufacturers but also the end-users, as it can lead to more affordable facial recognition devices on the market.

Key Innovations in Facial Recognition PCB Assembly

As technology continues to evolve, several innovations in PCB assembly for facial recognition are shaping the future of electronics.

Advanced Sensor Technologies

The integration of advanced sensors into PCBs has revolutionized facial recognition systems. High-resolution cameras and infrared sensors enable devices to capture clear images, even in low-light conditions. Innovations in sensor technology are essential for improving recognition accuracy and speed.

Machine Learning Algorithms

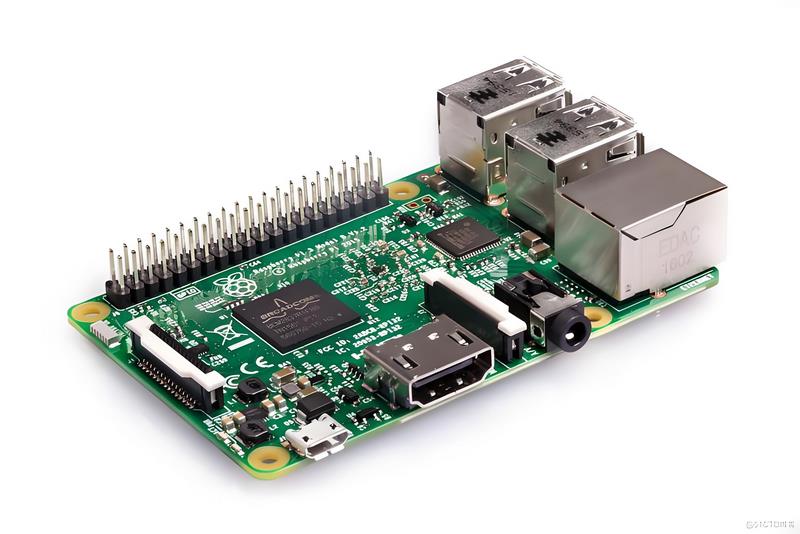

The adoption of machine learning algorithms within facial recognition systems has led to advancements in data processing capabilities. By embedding powerful microprocessors into PCBs, devices can analyze facial data more efficiently, resulting in quicker identification and verification processes.

Miniaturization of Components

One of the most significant trends in PCB assembly is the miniaturization of electronic components. Smaller components allow for more compact and portable facial recognition devices without compromising performance. This innovation opens up new opportunities for applications in mobile technology, security, and personal devices.

Understanding the PCB Manufacturing Process

The PCB manufacturing process consists of several critical steps that ensure the production of high-quality circuit boards.

Design Phase

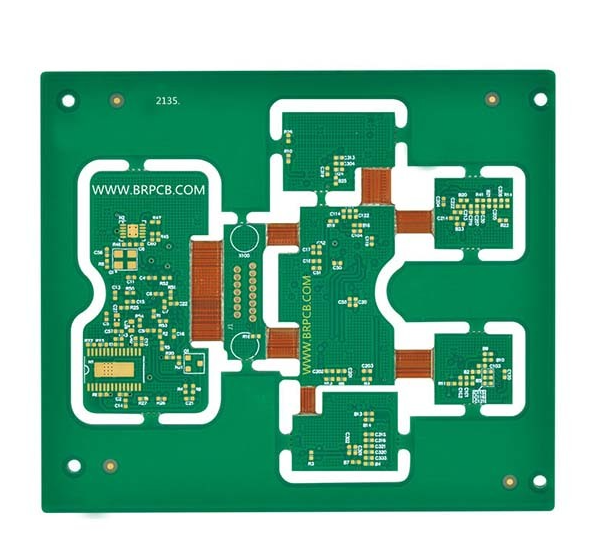

The process begins with designing the circuit board using software that allows engineers to visualize the layout of components. This phase is crucial for ensuring that all components fit seamlessly and function as intended.

Fabrication

Once the design is finalized, the fabrication phase involves creating the physical PCB. This includes etching copper layers, drilling holes for components, and applying protective coatings.

Assembly

The assembly phase follows fabrication and involves soldering the components onto the PCB. Techniques such as surface mount technology (SMT) and through-hole technology are used to ensure that components are securely attached.

Testing and Quality Control

After assembly, rigorous testing and quality control measures are implemented to verify that the PCBs function correctly. This step is vital to eliminate defects and ensure that the final product meets industry standards.

Applications of Facial Recognition Technology

Facial recognition technology powered by innovative PCB assembly is being utilized across various industries, enhancing security, convenience, and user experience.

Security and Surveillance

One of the most prominent applications of facial recognition is in security and surveillance. Government agencies and private organizations utilize these systems to monitor public spaces and enhance safety measures.

Smartphones and Personal Devices

Facial recognition technology is increasingly integrated into smartphones and personal devices, allowing users to unlock their devices with ease. As PCB assembly continues to advance, the implementation of this technology will become even more prevalent.

Retail and Customer Experience

In retail, facial recognition technology is used to personalize customer experiences, enabling targeted marketing and improved customer service. This application enhances engagement and allows retailers to better understand consumer behavior.

Challenges in Facial Recognition PCB Assembly

Despite the advancements in facial recognition technology and PCB assembly, several challenges persist.

Privacy Concerns

As facial recognition technology becomes more ubiquitous, concerns regarding privacy and data security have emerged. Manufacturers must implement robust security measures to protect users' data and address public apprehensions.

Regulatory Compliance

Regulatory frameworks surrounding facial recognition technology vary by region. Manufacturers must navigate these regulations to ensure compliance while developing innovative solutions.

Technical Limitations

Despite advancements, some technical limitations still exist, such as variations in lighting and angles affecting recognition accuracy. Continuous innovation in PCB assembly and sensor technology is crucial to overcoming these challenges.

Future Trends in Facial Recognition Technology

The future of facial recognition technology is promising, with several trends set to shape its development.

Integration with IoT

As the Internet of Things (IoT) continues to expand, facial recognition technology will increasingly integrate with connected devices. This synergy will enhance user experiences and automate processes across various applications.

AI-Powered Enhancements

Artificial Intelligence (AI) will play a pivotal role in advancing facial recognition technology. AI algorithms will enable systems to learn from data, improving accuracy and adaptability over time.

Cloud-Based Solutions

The shift towards cloud-based solutions will facilitate real-time processing and analysis of facial recognition data. This trend will enhance the scalability and accessibility of facial recognition systems, making them more efficient.

Conclusion

The innovations in facial recognition PCB assembly are transforming the landscape of electronics and affecting multiple sectors. From enhanced security measures to improved user experiences, the advancements in technology promise a future where facial recognition systems are more accurate, reliable, and efficient. As we continue to explore the possibilities within this field, the importance of high-quality PCB assembly will remain paramount in driving progress and ensuring that technology aligns with user needs and industry standards.

FAQs

What is PCB assembly in facial recognition technology?

PCB assembly in facial recognition technology involves the integration of electronic components on a printed circuit board to support the functionality of facial recognition systems.

How does facial recognition technology work?

Facial recognition technology analyzes facial features captured by cameras and compares them against a database to identify or verify individuals.

What are the key components of facial recognition systems?

Key components include cameras, sensors, processors, and memory units, all of which are integrated through PCB assembly.

What industries use facial recognition technology?

Facial recognition technology is used in security, retail, personal devices, and various other industries to enhance security and improve customer experiences.

What challenges does facial recognition technology face?

Challenges include privacy concerns, regulatory compliance, and technical limitations regarding accuracy and reliability in varying conditions.

Related news

Exploring the Future of AIoT PCB Assembly

2025-09-03

2025-08-27