Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

Understanding Elevator Control PCB Assembly: A Comprehensive Guide for Professionals

2026-01-22

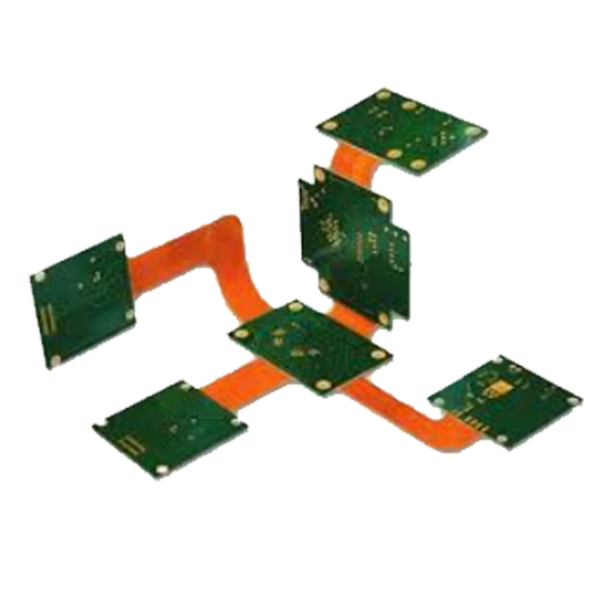

Elevator Control PCB Assembly plays a critical role in the operation and safety of elevator systems. As the heart of the elevator's control mechanism, the printed circuit board (PCB) is responsible for managing various functions, including motor control, safety systems, and user interfaces. Understanding the intricacies of Elevator Control PCB Assembly is essential for professionals in the electronic components industry, particularly those focused on specialized electronic devices.

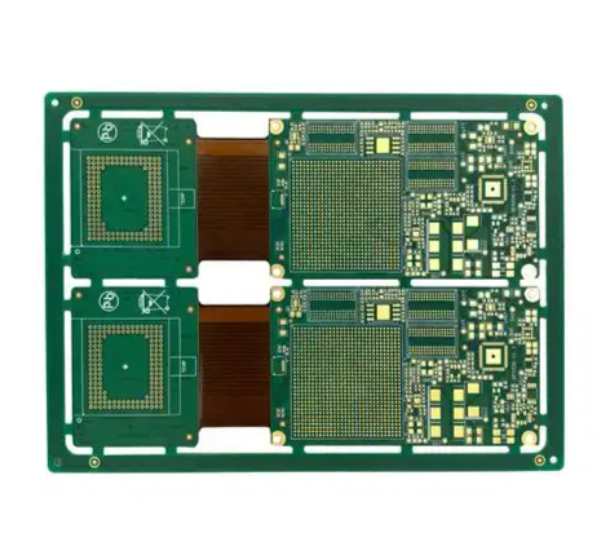

The design of an elevator control PCB must prioritize reliability and efficiency. Given that elevators operate in diverse environments, the assembly needs to withstand various factors, such as temperature fluctuations, humidity, and electromagnetic interference. One crucial factor in the design phase is the selection of appropriate materials. High-quality substrates and components must be chosen to ensure longevity and performance under normal and extreme operating conditions.

Another key aspect of Elevator Control PCB Assembly is the layout design. The arrangement of components on the PCB should minimize signal interference while maximizing power distribution efficiency. Utilizing techniques such as ground planes and controlled impedance traces can significantly enhance the overall functionality of the board. Each component's placement should be strategically planned, considering both electrical performance and ease of assembly.

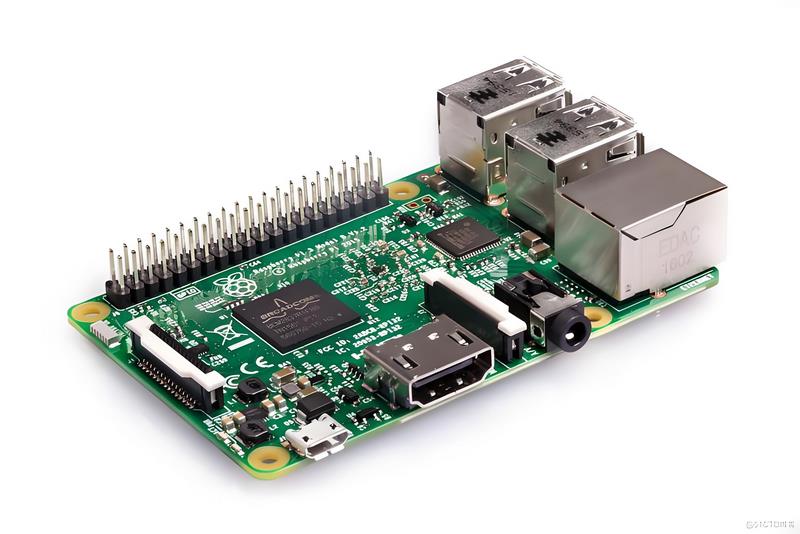

The manufacturing process of Elevator Control PCB Assembly involves several steps, including fabrication, component placement, soldering, and testing. Automated assembly techniques, such as surface mount technology (SMT), are commonly used to ensure high precision and efficiency. After the assembly process, rigorous testing is essential to verify that the PCB operates correctly under all expected conditions. Functional testing, thermal cycling, and stress testing are standard practices to ensure reliability.

In addition to technical considerations, regulatory compliance is another critical aspect of Elevator Control PCB Assembly. Manufacturers must adhere to various safety and performance standards set by organizations such as the International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI). Meeting these standards not only ensures the safety of elevator systems but also enhances marketability and consumer trust.

In conclusion, professionals involved in Elevator Control PCB Assembly must possess a comprehensive understanding of design principles, material selection, manufacturing processes, and regulatory requirements. By focusing on these elements, industry experts can contribute to the development of safe, efficient, and reliable elevator systems that meet the demands of modern infrastructure. As technology continues to evolve, staying updated on best practices and innovations in PCB assembly will be crucial for success in this specialized field.

The design of an elevator control PCB must prioritize reliability and efficiency. Given that elevators operate in diverse environments, the assembly needs to withstand various factors, such as temperature fluctuations, humidity, and electromagnetic interference. One crucial factor in the design phase is the selection of appropriate materials. High-quality substrates and components must be chosen to ensure longevity and performance under normal and extreme operating conditions.

Another key aspect of Elevator Control PCB Assembly is the layout design. The arrangement of components on the PCB should minimize signal interference while maximizing power distribution efficiency. Utilizing techniques such as ground planes and controlled impedance traces can significantly enhance the overall functionality of the board. Each component's placement should be strategically planned, considering both electrical performance and ease of assembly.

The manufacturing process of Elevator Control PCB Assembly involves several steps, including fabrication, component placement, soldering, and testing. Automated assembly techniques, such as surface mount technology (SMT), are commonly used to ensure high precision and efficiency. After the assembly process, rigorous testing is essential to verify that the PCB operates correctly under all expected conditions. Functional testing, thermal cycling, and stress testing are standard practices to ensure reliability.

In addition to technical considerations, regulatory compliance is another critical aspect of Elevator Control PCB Assembly. Manufacturers must adhere to various safety and performance standards set by organizations such as the International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI). Meeting these standards not only ensures the safety of elevator systems but also enhances marketability and consumer trust.

In conclusion, professionals involved in Elevator Control PCB Assembly must possess a comprehensive understanding of design principles, material selection, manufacturing processes, and regulatory requirements. By focusing on these elements, industry experts can contribute to the development of safe, efficient, and reliable elevator systems that meet the demands of modern infrastructure. As technology continues to evolve, staying updated on best practices and innovations in PCB assembly will be crucial for success in this specialized field.

Related news