Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

Top Considerations for Successful Facial Recognition PCB Assembly Projects

2026-01-19

Top Considerations for Successful Facial Recognition PCB Assembly Projects

Introduction to Facial Recognition Technology

Facial recognition technology has revolutionized how we interact with devices and systems. By employing advanced algorithms and hardware, it analyzes facial features to verify or identify individuals. The integration of this technology into various applications, including smartphones, surveillance systems, and customer interaction platforms, underscores the importance of robust PCB assembly processes.

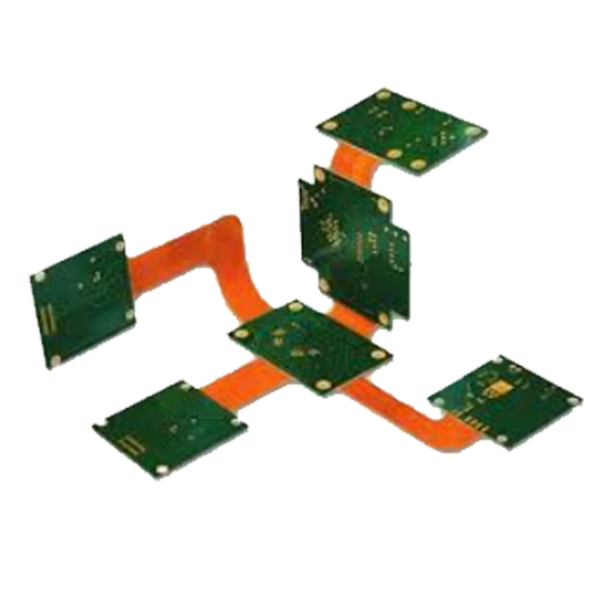

Understanding PCB Assembly in Facial Recognition Systems

PCB (Printed Circuit Board) assembly is a critical component in the development of facial recognition systems. It provides the foundation for connecting various electronic components, enabling seamless functionality. A well-designed PCB not only enhances the performance of the facial recognition system but also contributes to its reliability.

Key Components of Facial Recognition PCBs

To ensure optimal performance of facial recognition systems, several critical components must be considered during the PCB assembly process:

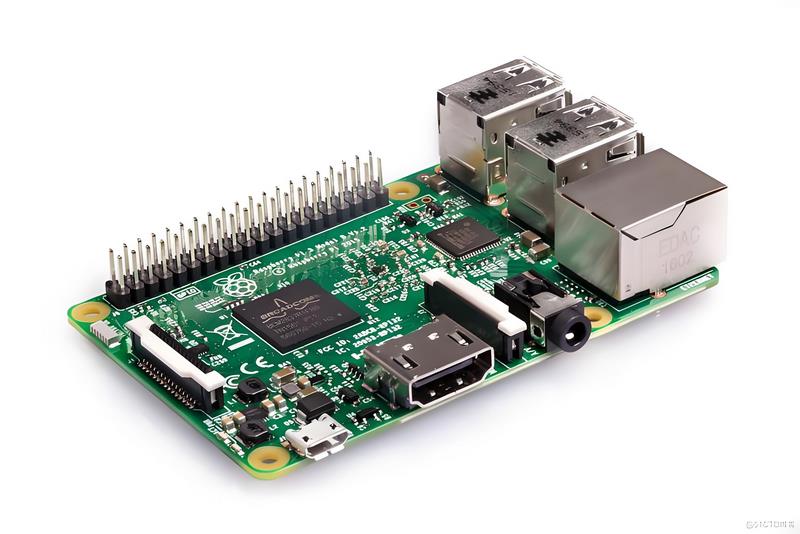

Microcontrollers and Processors

At the heart of any facial recognition system is the microcontroller or processor. These components manage data processing and algorithm execution. Selecting the right processor is vital for achieving the required speed and accuracy in facial recognition tasks.

Image Sensors

Image sensors capture facial features and are crucial for the system's effectiveness. When assembling PCBs for facial recognition, ensure that the image sensors used are of high quality and capable of delivering clear, high-resolution images.

Memory Modules

Memory plays a significant role in the performance of facial recognition systems. Adequate RAM and storage are necessary for processing and storing data efficiently. Choose memory modules that support rapid data access to enhance system responsiveness.

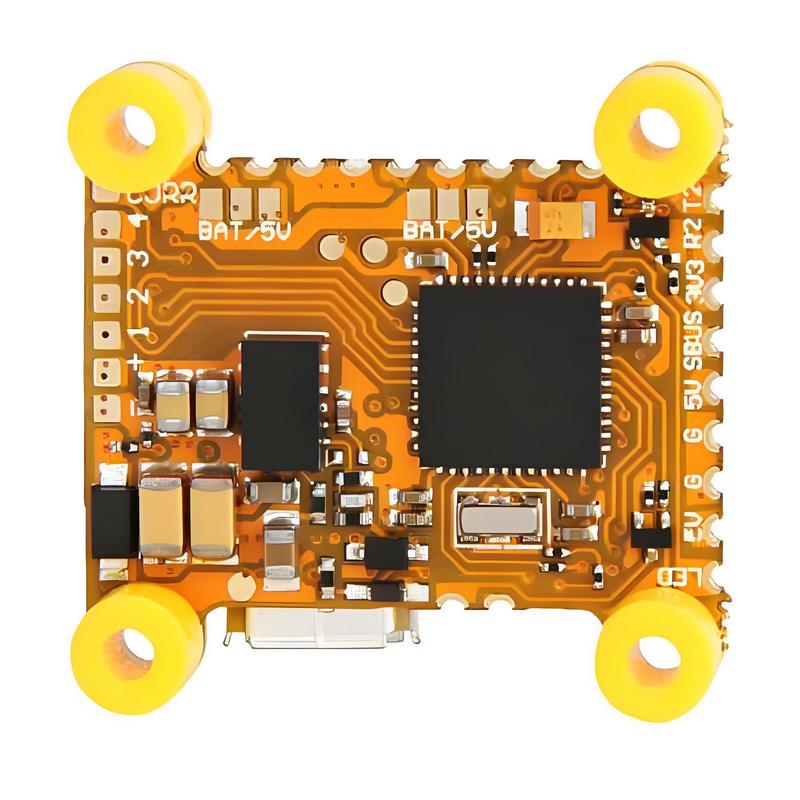

Power Supply Components

Reliable power supply components are essential for maintaining the stability of the PCB assembly. Ensure that the power supply can handle peak loads and provides clean, consistent power to all components.

Design Considerations for Facial Recognition PCBs

The design phase of PCB assembly is critical for creating a successful facial recognition system. Several factors should be taken into account:

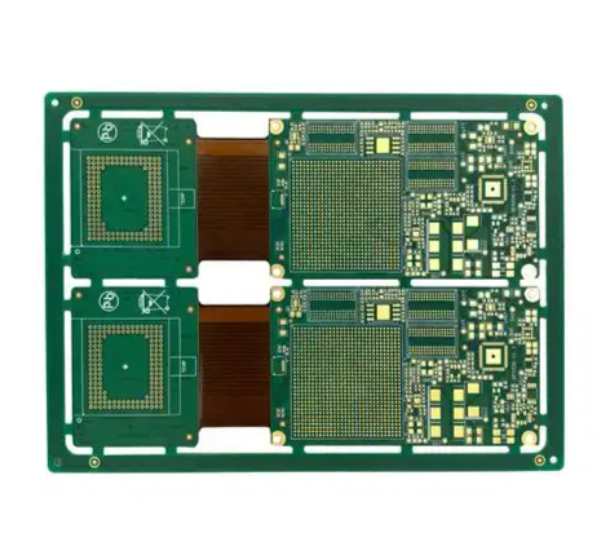

Layout and Routing

Effective layout and routing are crucial for minimizing signal interference and ensuring efficient data transmission. Consider the following:

- **Signal Integrity**: Maintain short traces for high-speed signals to reduce latency and improve performance.

- **Ground Plane Design**: Employ a solid ground plane to minimize electromagnetic interference (EMI) and enhance stability.

Thermal Management

Facial recognition systems can generate significant heat during operation. Implement adequate thermal management solutions, such as heat sinks and thermal vias, to prevent overheating and ensure longevity.

Component Placement Strategy

Strategic component placement not only enhances performance but also simplifies troubleshooting and repair. Group related components together and ensure there is sufficient spacing to avoid interference.

Manufacturing Considerations for PCB Assembly

Once the design is finalized, the manufacturing process must be meticulously planned to ensure high-quality PCB assembly.

Choosing the Right Manufacturer

Selecting a reliable PCB manufacturer is crucial. Look for manufacturers with experience in assembling PCBs for facial recognition systems. Check for certifications such as ISO 9001 to ensure they meet industry standards.

Quality Control Processes

Implement rigorous quality control measures throughout the assembly process. This includes:

- **Visual Inspections**: Regular visual checks can help identify defects early in the process.

- **Functional Testing**: Conduct functional tests on assembled PCBs to ensure they perform as intended.

Supply Chain Management

Efficient supply chain management is vital for timely project completion. Maintain strong relationships with component suppliers to ensure availability and quality of parts.

Regulatory Compliance in Facial Recognition PCB Projects

Facial recognition technologies are subject to various regulations and standards. Understanding these requirements is essential for successful project completion.

Data Privacy and Security Standards

Facial recognition systems often handle sensitive data. Compliance with data protection regulations, such as GDPR or CCPA, is crucial to protect user privacy and avoid legal complications.

Electromagnetic Compatibility (EMC) Regulations

Ensure that the PCB assembly complies with EMC regulations to avoid interference with other electronic devices. This is particularly important in environments where multiple electronic systems operate simultaneously.

Testing and Validation of Facial Recognition PCBs

Testing is a critical phase in the PCB assembly process. It ensures that the facial recognition system meets performance specifications and can handle real-world scenarios.

Functional Testing

Conduct thorough functional tests to validate the performance of the facial recognition system. This includes testing the accuracy of facial detection and recognition under various conditions.

Stress Testing

Stress testing evaluates how the system performs under extreme conditions. This helps identify potential weaknesses and ensures long-term reliability.

Final Assembly and Deployment Strategies

Once testing is complete, the final assembly and deployment of the facial recognition systems can begin.

Integration with Other Systems

Consider how the facial recognition system will integrate with existing infrastructure. Smooth integration is essential for maximizing the system's effectiveness.

Documentation and User Training

Provide comprehensive documentation and training for users. This ensures they understand how to operate the system effectively and troubleshoot any issues that may arise.

Future Trends in Facial Recognition PCB Technology

As technology evolves, so do facial recognition systems. Staying informed about future trends can help in adapting your PCB assembly strategies accordingly.

Advancements in AI and Machine Learning

The integration of AI and machine learning will enhance the capabilities of facial recognition systems. PCB assemblies may need to accommodate more powerful processors to handle complex algorithms.

Increased Focus on Privacy and Ethics

With growing concerns over privacy, future facial recognition systems will likely prioritize secure data handling and transparent usage policies. PCB designs will need to reflect these priorities to ensure compliance.

Conclusion

Creating successful facial recognition PCB assembly projects requires a thorough understanding of various components, design strategies, and manufacturing processes. By considering key factors such as component selection, design, manufacturing quality, and regulatory compliance, you can enhance the performance and reliability of your facial recognition systems. As technology continues to advance, staying abreast of trends will ensure your projects remain competitive and effective in the ever-evolving landscape of facial recognition technology.

FAQs About Facial Recognition PCB Assembly

1. What is the most critical component in a facial recognition PCB?

The microcontroller or processor is often considered the most critical component, as it manages data processing and algorithm execution.

2. How can I ensure the quality of my PCB assembly?

Implementing rigorous quality control processes, such as visual inspections and functional testing, can help ensure the quality of your PCB assembly.

3. What are the regulatory standards I should consider?

Key regulations include data privacy laws (like GDPR) and electromagnetic compatibility (EMC) regulations, which ensure that your systems do not interfere with other devices.

4. How does thermal management affect PCB assembly?

Effective thermal management prevents overheating, which can lead to component failure and reduced system longevity.

5. What future trends should I be aware of in facial recognition technology?

Future trends include advancements in AI and machine learning, increased focus on privacy and ethics, and the development of more sophisticated image sensors.

By considering these crucial aspects in your PCB assembly projects, you can ensure a successful implementation of facial recognition technology that meets the demands of today’s market.

Related news