Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

Quality Aiot Pcb Assembly

2025-08-27

Introduction

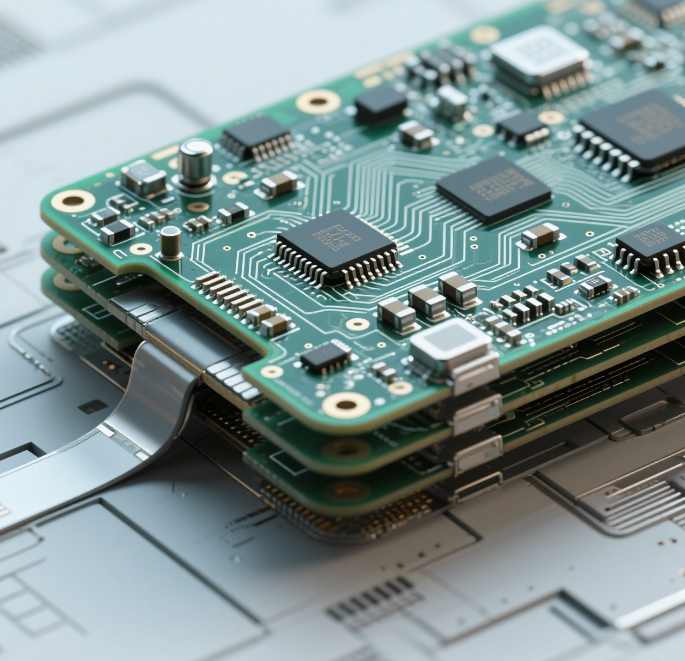

Welcome to the interconnected world of communication and AIoT PCB assembly, which refers to the production and assembly of printed circuit boards used in communication devices and AIoT applications. These assemblies require high precision, reliability, and signal integrity to support functions such as data transmission, wireless connectivity, edge computing, and intelligent control.

We offer one-stop PCBA solutions for communication modules (e.g., 4G/5G, Wi-Fi, Bluetooth), smart gateways, IoT terminals, and AI-integrated devices. With advanced SMT lines, strict quality control, and support for high-frequency, multi-layer PCB designs, we ensure consistent performance and fast time-to-market for our customers in the rapidly evolving communication and AIoT sectors.

Our services include PCB fabrication, component sourcing, assembly, testing, and complete system integration, tailored to meet the diverse requirements of smart connected products.

Understanding Communication and AIoT Assembly PCBs

Communication and AIoT Assembly PCBs are specialized printed circuit boards designed for devices that require wireless connectivity, data processing, and intelligent control. These PCBs are the backbone of modern smart systems such as routers, gateways, 5G modules, edge computing devices, smart meters, and AI-based sensors.

They often involve high-speed signal transmission, RF design, multi-layer structures, and integration of complex components like microcontrollers, AI chips, and wireless modules (e.g., Wi-Fi, Bluetooth, NB-IoT, LoRa). Assembly of such boards demands high-precision SMT technology, rigorous testing (ICT/FCT/AXI), and strong EMC (Electromagnetic Compatibility) control.

In the PCBA industry, manufacturers must not only ensure quality soldering and accurate component placement but also focus on thermal management, signal integrity, and long-term reliability—key factors for success in communication and AIoT products.

Essential Components of Communication and AIoT PCB Assembly

|

Component |

Function / Description |

|

Microcontrollers / MCUs |

Control system logic, data processing, and peripheral communication |

|

Wireless Modules |

Provide wireless connectivity (Wi-Fi, Bluetooth, LoRa, NB-IoT, LTE, 5G, etc.) |

|

AI Chips / NPUs |

Handle machine learning tasks and intelligent decision-making |

|

RF Components |

Include antennas, filters, and RF ICs for signal transmission and reception |

|

Memory Chips |

Store firmware, operational data, and logs (e.g., Flash, EEPROM, RAM) |

|

Sensors |

Collect environmental or user data (e.g., temperature, motion, pressure) |

|

Power Management ICs (PMICs) |

Manage and distribute power efficiently across the board |

|

Connectors & Interfaces |

Enable communication with external devices (USB, UART, I2C, SPI, Ethernet, SIM, etc.) |

|

Crystal Oscillators |

Generate precise timing signals for system synchronization |

|

Passive Components |

Resistors, capacitors, inductors – essential for filtering, stability, and signal shaping |

|

Protection Components |

TVS diodes, ESD protectors, and fuses to prevent electrical damage |

|

PCB Substrate & Stack-Up |

Multi-layer materials (e.g., FR4, Rogers) for signal integrity and high-speed design |

Best Practices for communication and AIoT PCB Assembly

| Category | Best Practice |

| Design & Layout |

- Use controlled impedance routing for high-speed and RF signals - Minimize EMI by using proper grounding, shielding, and layer stack-up -Follow design-for-manufacturing (DFM) and design-for-test (DFT) guidelines - Place sensitive analog and RF components away from noisy digital circuits - Keep antenna areas clear of ground planes and traces |

| Component Selection |

-Choose high-reliability components rated for IoT/industrial environments -Verify compatibility and communication protocols (I2C, UART, SPI, etc.) - Use certified wireless modules for faster compliance and integration |

| Assembly Process |

-Employ high-precision SMT machines for tight-pitch and miniaturized components -Use proper solder paste for fine-pitch, high-density interconnects (HDI) -Handle moisture-sensitive devices (MSDs) under appropriate MSL conditions -Conduct X-ray inspection for BGA and hidden solder joints |

| Testing & Validation |

-Implement ICT (In-Circuit Testing) and FCT (Functional Circuit Testing) - Perform RF testing for signal strength, interference, and modulation accuracy - Run environmental and thermal tests for reliability in various operating conditions -Ensure software/firmware is tested in real hardware conditions (burn-in, stress tests) |

| Compliance & Reliability |

-Design with certification in mind (CE, FCC, RoHS, etc.) - Plan for ESD protection and surge suppression -Focus on long-term supply chain stability for critical parts |

Advanced Technologies and Innovations in Communication and AIoT PCB Assembly

As the demand for intelligent connectivity and real-time data processing continues to grow, the assembly of communication and AIoT (Artificial Intelligence of Things) PCBs has rapidly evolved to incorporate cutting-edge technologies and innovative manufacturing techniques. These advancements enable the production of smaller, faster, and more reliable smart devices that support 5G communication, edge computing, and AI-driven applications. From high-density interconnect (HDI) and flexible PCBs to AI-assisted testing and advanced material usage, manufacturers are leveraging a range of new solutions to meet the stringent performance, reliability, and environmental requirements of next-generation communication and AIoT systems. This transformation is critical to supporting the global expansion of smart cities, industrial automation, and connected consumer electronics.

Customization and Flexibility in PCB Assembly Services

In today's fast-paced electronics industry, customization and flexibility have become essential features of modern PCB assembly services. As products become more specialized and application-specific—especially in fields like AIoT, communication, automotive, and medical—manufacturers must offer tailored solutions to meet unique customer requirements.

Flexible PCB assembly services allow for:

Custom board shapes, sizes, and layouts

Multi-layer and rigid-flex configurations

Specific component sourcing (including customer-supplied parts)

Low-to-high volume production scalability

Support for quick-turn prototyping to full-scale manufacturing

Firmware programming, functional testing, and final product integration

Moreover, manufacturers provide design-for-manufacturing (DFM) and design-for-test (DFT) support to ensure that even highly customized PCBs maintain quality, reliability, and cost-efficiency. This adaptability helps customers reduce time-to-market, respond to evolving technology trends, and scale efficiently from development to deployment.

Ensuring Reliability and Longevity

reliability and longevity are critical, especially for applications in communication, AIoT, automotive, industrial control, and medical devices where failures can lead to system-wide consequences. To ensure long-term performance and minimal failure rates, manufacturers must implement best practices across design, material selection, assembly, and testing.

Key strategies include:

High-quality materials: Use of durable PCB substrates (e.g., FR4, polyimide, Rogers) and components rated for temperature, humidity, and vibration resistance.

Robust soldering processes: Precision reflow soldering, wave soldering, and selective soldering to avoid cold joints, voids, or bridging.

Conformal coating and encapsulation: Protection against moisture, dust, corrosion, and chemical exposure in harsh environments.

Thermal management: Heat sinks, thermal vias, and copper pours to prevent overheating in dense or high-power designs.

Design for Reliability (DfR): Inclusion of redundant traces, surge protection, and conservative current/voltage margins.

Environmental and stress testing: Thermal cycling, burn-in tests, vibration, ESD, and salt spray tests to simulate real-world conditions.

Traceability and process control: Full documentation of component batches, assembly conditions, and inspection data for quality assurance and warranty traceability.

By prioritizing these practices, PCB assembly providers can deliver products that perform reliably over extended lifespans, even in mission-critical or demanding operating conditions.

Conclusion

Communication and AIoT PCB Assembly represents the forefront of modern electronics manufacturing, where precision, performance, and adaptability converge. With the integration of advanced technologies such as HDI, flexible PCBs, AI chips, and 5G-ready materials, manufacturers are enabling the development of smarter, faster, and more compact devices. Customization and flexibility in assembly services further empower businesses to bring unique, application-specific products to market efficiently.

Equally important is the commitment to reliability and longevity, achieved through high-quality components, rigorous testing, robust process control, and thoughtful design. As the demand for intelligent and connected systems continues to rise, the ability to deliver innovative, scalable, and dependable PCB solutions will be key to staying competitive in the rapidly evolving landscape of AIoT and communication technologies.

Ready to Elevate Your PCB Projects to New Heights?

Whether you're developing next-generation communication devices or innovative AIoT solutions, we're here to turn your vision into reality. With advanced technologies, flexible manufacturing, and uncompromising quality standards, we deliver PCB assembly services that are smart, scalable, and built to last.

Contact us today to discuss your project needs and discover how our tailored solutions can accelerate your product development — from prototype to mass production.

Let's build the future, together.

Quality Aiot PCB Assembly is designed to meet the growing demand for reliable and high-performance electronic solutions in the field of Artificial Intelligence of Things. With advanced production technology and strict quality control, our Quality Aiot PCB Assembly ensures stable performance, excellent connectivity, and durability for a wide range of smart applications. By choosing our Quality Aiot PCB Assembly, you benefit from precise circuit design, efficient power management, and seamless integration with IoT devices, making it ideal for industrial automation, smart homes, healthcare, and communication systems.

Related news