Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

Revolutionizing Intelligent Mobility: How PCB Boards are Redefining Automotive Electronics

2025-06-18

The automotive electronics industry is undergoing a profound transformation from traditional to intelligent and connected. The PCB board (Printed Circuit Board), as the hardware cornerstone of the automotive electronics system, penetrates all aspects comprehensively, reshaping the automotive electronics ecosystem and leading intelligent travel to a new stage.

In the evolution of autonomous driving technology, the PCB board undertakes a key mission. From the sensor system for environmental perception, to the domain controller for decision - making and control, and then to the power and chassis control systems at the execution level, the PCB board enables accurate signal transmission and stable system operation. The high - precision millimeter - wave radar and lidar required for autonomous driving rely on high - performance PCB boards for their internal signal processing and data transmission. Using PCB materials with high - frequency and high - speed characteristics and optimized circuit design, it can quickly process massive point cloud data, distance information, and object recognition signals, providing an accurate basis for environmental perception for the autonomous driving system. In the autonomous driving domain controller, the highly integrated and multi - layered PCB board integrates high - performance chips, communication modules, and control circuits to achieve the fusion processing and decision - making output of multi - sensor data. Just like the "intelligent brain" of a car, it accurately controls the acceleration, deceleration, and steering of the vehicle according to real - time road conditions and environmental information, ensuring the safety and efficiency of autonomous driving.

The enrichment and upgrading of the in - vehicle intelligent system also cannot do without the support of the PCB board. In the smart cockpit, from the high - definition central control display, full - LCD instrument panel to the in - vehicle entertainment system and vehicle - to - network module, the PCB board realizes the circuit connection and signal interaction of various devices. High - definition display relies on the high - quality transmission of video signals by the PCB board. Using a low - noise and high - bandwidth circuit design, it ensures the smoothness and clarity of the picture. For the realization of vehicle - to - network functions, such as communication between vehicles and the cloud, vehicle - to - vehicle (V2V), and vehicle - to - infrastructure (V2I), the wireless communication module circuit integrated by the PCB board supports high - speed data transmission and stable connection, allowing the vehicle to obtain real - time traffic information, online entertainment resources, etc., enhancing the riding experience while promoting the car to become an intelligent mobile terminal.

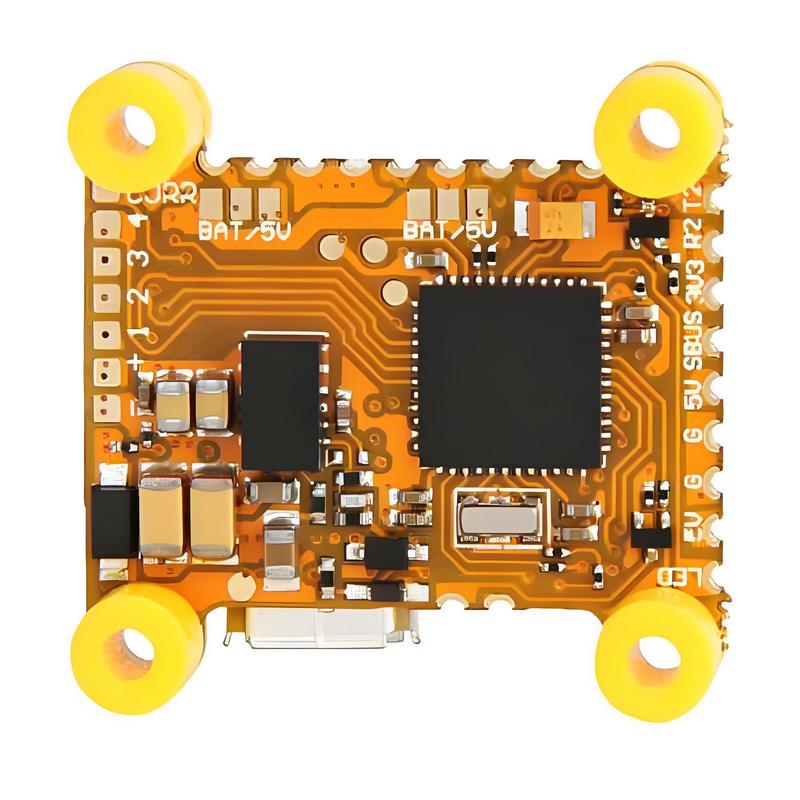

Under the electrification trend of automotive electronics, the role of the PCB board in the power and energy management system is prominent. In the battery management system (BMS) of electric vehicles, the PCB board integrates circuits for battery state monitoring, equalization control, and safety protection. It collects parameters such as voltage, current, and temperature of the battery pack in real time, adjusts the battery charging and discharging process through intelligent algorithms, prevents over - charging and over - discharging, and ensures battery safety and long service life. In the motor control system, the high - power - density PCB board undertakes the interconnection of power devices such as IGBT (Insulated Gate Bipolar Transistor). The optimized heat dissipation design and circuit layout reduce power loss and improve motor drive efficiency, helping electric vehicles achieve stronger power and longer battery life.

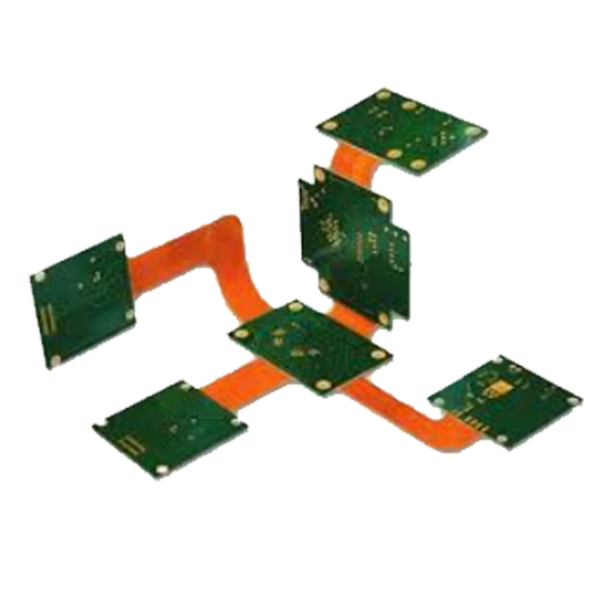

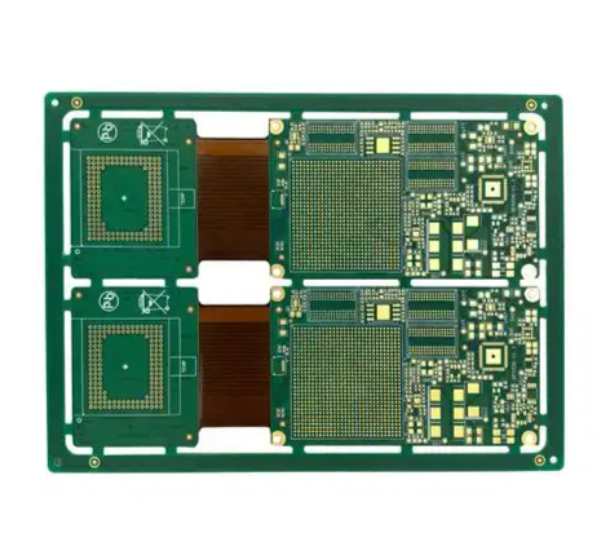

As the functions of automotive electronics continue to expand, the demand for PCB boards is becoming increasingly diverse. On the one hand, higher integration is pursued to adapt to the limited space inside the car. Multi - layer and high - density interconnect (HDI) PCB boards have become the mainstream, realizing complex circuit connections in a very small area; on the other hand, reliability is strengthened. The car operating environment is complex, facing temperature changes, vibration, electromagnetic interference, etc. The PCB board needs to pass strict reliability tests, such as temperature cycle tests and vibration tests, to ensure long - term stable operation.

From the perspective of the supply chain, the production of PCB boards for automotive electronics needs to follow strict industry standards and quality control systems. Material selection should take into account both performance and cost, and the production process focuses on precision and consistency. From the cutting of copper - clad laminates, circuit etching to the production of the solder mask, each step affects the final product quality. At the same time, with the accelerated advancement of the new four modernizations of automobiles (intelligentization, connectedness, electrification, and sharing), PCB board enterprises are also continuously innovating, deeply collaborating with automotive electronics manufacturers, and jointly developing products to meet the needs of future automobiles, such as high - speed PCB boards to meet higher computing power requirements and high - voltage - resistant PCB boards to adapt to the 800V high - voltage platform.

It can be predicted that the PCB board will continue to be the core support of the automotive electronics ecosystem, playing a key role in improving the level of autonomous driving, optimizing the smart cockpit experience, and breaking through electrification technologies. It will continuously reshape the functional boundaries and industrial pattern of automotive electronics, leading intelligent travel to continuously transform in a safer, smarter, and greener direction, making the car no longer just a means of transportation, but an indispensable intelligent node in the smart travel ecosystem.

Related news