Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

How AIoT PCB Assembly is Transforming Electronic Communication

2026-01-13

How AIoT PCB Assembly is Transforming Electronic Communication

Table of Contents

- Introduction to AIoT and PCB Assembly

- Understanding the Role of PCB in Electronic Devices

- The Synergy of AI and IoT in PCB Assembly

- Key Benefits of AIoT PCB Assembly

- Applications of AIoT PCB in Electronic Communication

- Challenges in AIoT PCB Assembly

- Future Trends in AIoT and PCB Technology

- Conclusion

- FAQs

Introduction to AIoT and PCB Assembly

The convergence of artificial intelligence (AI) and the Internet of Things (IoT) has given birth to a revolutionary field known as AIoT. This innovative amalgamation seeks to enhance the capabilities of connected devices through intelligent data processing and machine learning. The backbone of many electronic devices, printed circuit board (PCB) assembly plays a pivotal role in facilitating AIoT applications. By integrating AI with IoT solutions, PCB assembly is empowering devices to communicate more effectively, leading to unprecedented transformations in electronic communication.

Understanding the Role of PCB in Electronic Devices

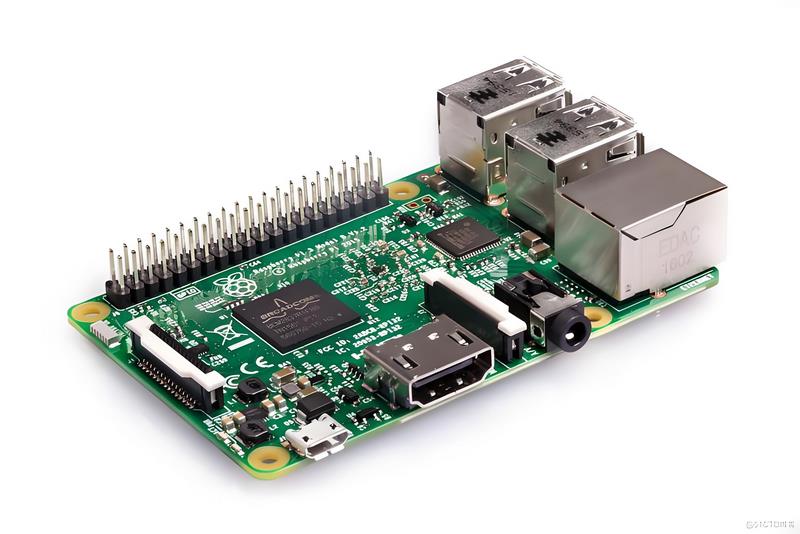

PCBs are crucial components in virtually all electronic devices, serving as the foundation for electrical connections and component integration. They provide the necessary pathways for signals to travel between components, enabling devices to function efficiently. In the context of AIoT, PCBs are being designed to accommodate advanced functionalities, such as real-time data processing and machine learning algorithms. This shift not only improves device performance but also paves the way for smarter communication systems.

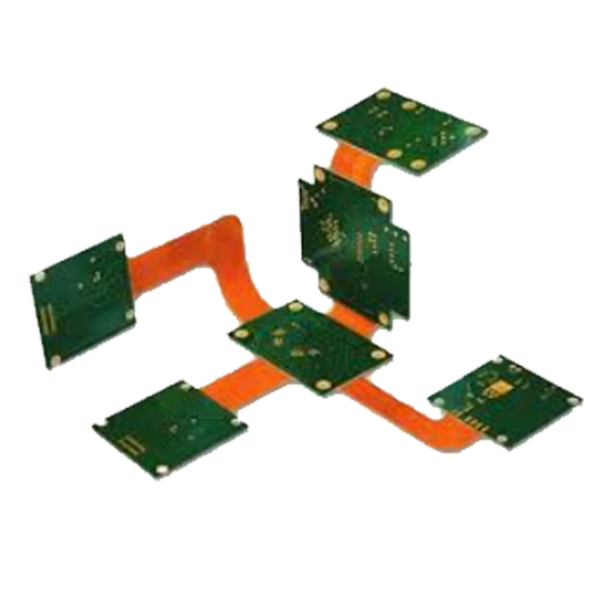

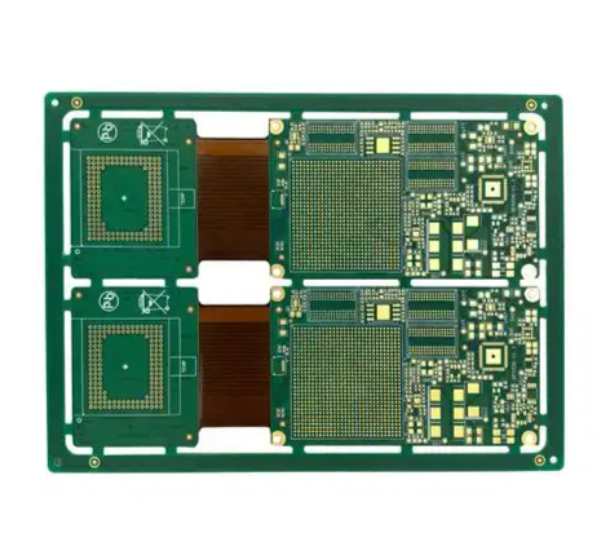

The Evolution of PCB Design

Over the years, PCB design has evolved significantly, adapting to the increasing complexity of electronic devices. Traditional PCBs have transitioned from simple, single-layer boards to sophisticated multi-layer designs that can support a vast array of components. This evolution has been driven by the need for miniaturization, improved performance, and enhanced connectivity, all of which are essential for AIoT applications.

The Synergy of AI and IoT in PCB Assembly

AI and IoT are not just complementary technologies; their integration into PCB assembly is creating a new paradigm for electronic communication. By embedding AI capabilities directly into PCBs, devices can process data locally, enabling quicker decision-making and reducing latency. This not only enhances the efficiency of communication systems but also improves the overall user experience.

How AI Enhances PCB Functionality

AI algorithms can analyze vast amounts of data in real-time, allowing devices to adapt to changing conditions and user behaviors. For instance, a smart home device equipped with AIoT PCB can learn a user's preferences over time, adjusting its settings for optimal functionality. This level of adaptability is transforming the way we interact with technology, making communication more intuitive and responsive.

Key Benefits of AIoT PCB Assembly

The integration of AI and IoT in PCB assembly offers numerous benefits that are reshaping electronic communication. These advantages include:

1. Enhanced Connectivity

AIoT PCBs facilitate seamless connectivity between devices, enabling them to communicate more effectively. This connectivity is crucial for applications such as smart cities, where multiple devices need to share data in real-time to optimize resource usage and enhance user experience.

2. Improved Efficiency

With AI processing data directly on the PCB, devices can operate more efficiently. This leads to reduced power consumption and longer battery life, especially critical for portable devices.

3. Real-Time Data Processing

AIoT PCBs enable real-time data processing, allowing devices to respond instantly to changes in their environment. This capability is essential for applications such as autonomous vehicles and smart industrial systems.

4. Increased Reliability

By incorporating AI into the PCB design, manufacturers can enhance the reliability of electronic devices. AI can predict potential failures and optimize performance, reducing downtime and maintenance costs.

5. Scalability

AIoT PCB solutions are designed to be scalable, allowing manufacturers to easily upgrade and expand their systems as technology advances. This flexibility is vital for businesses looking to stay competitive in a rapidly evolving market.

Applications of AIoT PCB in Electronic Communication

The impact of AIoT PCB assembly on electronic communication is profound, with applications spanning across various industries. Here are some notable examples:

1. Smart Home Devices

AIoT PCBs are at the heart of smart home technologies, enabling devices like smart thermostats, security systems, and voice assistants to communicate seamlessly. These devices learn user preferences and automate tasks, enhancing convenience and security.

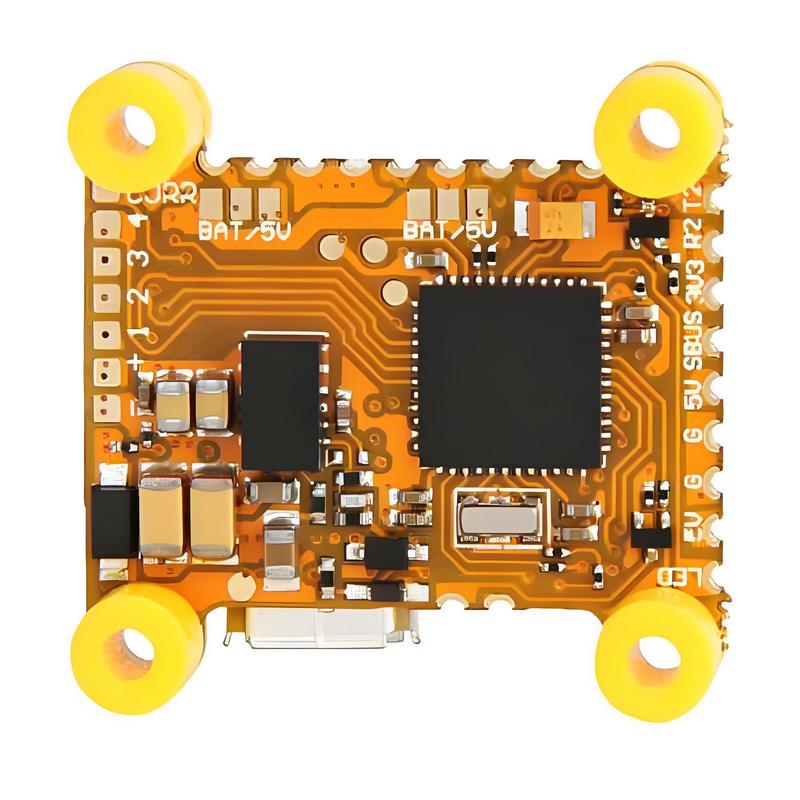

2. Wearable Technology

Wearable devices, such as fitness trackers and smartwatches, rely on AIoT PCBs to provide real-time health monitoring and communication. They analyze data from sensors and deliver insights to users, promoting healthier lifestyles.

3. Industrial Automation

In industrial settings, AIoT PCBs are transforming communication between machines and systems. They enable predictive maintenance and optimize production processes, significantly improving operational efficiency.

4. Healthcare Solutions

AIoT PCBs are revolutionizing healthcare by enabling remote patient monitoring and telemedicine solutions. These systems facilitate real-time communication between patients and healthcare providers, improving care delivery.

5. Automotive Technologies

The automotive industry is increasingly adopting AIoT PCB technology for enhanced communication between vehicles and infrastructure. This integration supports advanced driver-assistance systems (ADAS) and paves the way for autonomous driving.

Challenges in AIoT PCB Assembly

Despite the numerous benefits, the integration of AI and IoT into PCB assembly presents several challenges:

1. Design Complexity

As PCB designs become more complex to accommodate AI functionalities, manufacturers face challenges in maintaining quality and reliability. Ensuring that all components work seamlessly together is critical for performance.

2. Cost Considerations

Integrating AI capabilities into PCBs can increase production costs. Manufacturers must find a balance between advanced features and affordability to remain competitive.

3. Security Concerns

With increased connectivity comes heightened security risks. Ensuring that AIoT devices are secure from cyber threats is paramount, requiring robust encryption and data protection measures.

4. Regulatory Compliance

Navigating the regulatory landscape for AIoT devices can be challenging. Manufacturers must adhere to various standards and regulations, which may vary by region and application.

Future Trends in AIoT and PCB Technology

The future of AIoT and PCB technology promises exciting developments that will further enhance electronic communication:

1. Advancements in AI Algorithms

As AI algorithms continue to evolve, we can expect more sophisticated data processing capabilities integrated into PCBs. This will enable even smarter devices capable of learning and adapting in real-time.

2. Increased Miniaturization

Future PCBs will likely become even smaller while increasing their functionality. This miniaturization will drive the development of more compact and efficient devices.

3. Enhanced Interoperability

As more devices become interconnected, the need for enhanced interoperability will grow. Future AIoT PCBs will be designed to communicate seamlessly across various platforms and protocols.

4. Sustainable Practices

Sustainability will play a crucial role in the future of AIoT PCB assembly. Manufacturers will need to adopt eco-friendly materials and processes to meet growing environmental concerns.

Conclusion

AIoT PCB assembly is undeniably transforming the landscape of electronic communication. By integrating artificial intelligence with the Internet of Things, we are witnessing a new era of connectivity and efficiency. From smart home devices to industrial applications, the potential for AIoT PCB technology is vast and continuously evolving. As we face challenges in design, cost, and security, the focus on innovation will be essential in realizing the full potential of this transformative technology.

FAQs

1. What is AIoT?

AIoT stands for Artificial Intelligence of Things, which combines artificial intelligence and the Internet of Things to enhance device capabilities and communication.

2. How does AIoT PCB assembly improve electronic devices?

AIoT PCB assembly enhances electronic devices by enabling real-time data processing, improving connectivity, and increasing efficiency through the integration of AI technologies.

3. What industries benefit from AIoT PCB technology?

Industries such as healthcare, automotive, smart homes, and industrial automation benefit significantly from AIoT PCB technology.

4. What challenges do manufacturers face with AIoT PCBs?

Manufacturers face challenges related to design complexity, cost considerations, security risks, and regulatory compliance when integrating AI into PCBs.

5. What are the future trends in AIoT and PCB technology?

Future trends include advancements in AI algorithms, increased miniaturization of PCBs, enhanced interoperability, and a focus on sustainable practices in manufacturing.

Related news