Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

Driving the Green Energy Revolution: How PCB Boards Innovate New Energy Equipment

2025-06-18

The new energy industry, as a key engine for promoting global green development and achieving the goal of carbon neutrality, is constantly seeking technological breakthroughs and efficiency improvements. The PCB board (Printed Circuit Board), with its core position in the field of electronic hardware, deeply drives the innovation of new energy equipment and empowers the great strides of green energy transformation.

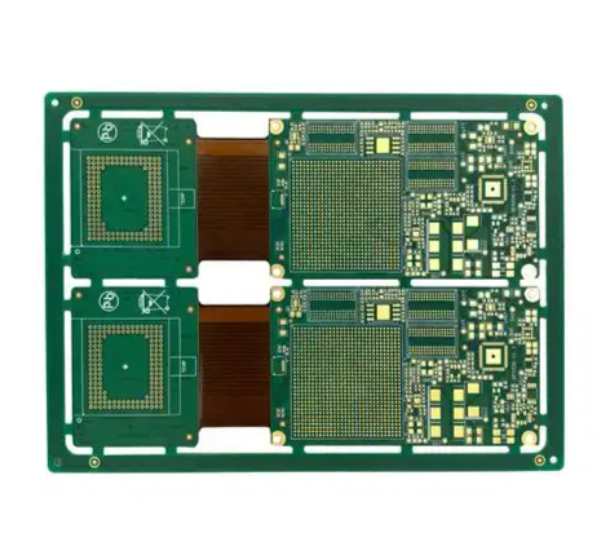

In the photovoltaic industry, the photovoltaic inverter, as the "heart" of the photovoltaic system, the PCB board is the key carrier for its internal circuit connection and signal processing. The high - performance PCB board uses materials with high temperature resistance and high insulation performance to adapt to the complex environment of high temperature, high humidity and strong ultraviolet rays in outdoor photovoltaic power stations. Its optimized circuit layout can efficiently integrate power modules, control modules and communication modules to achieve rapid conversion and stable output of photovoltaic power. In large - scale centralized photovoltaic power stations, the PCB board helps the inverter accurately control the power generation and grid connection of multiple groups of photovoltaic arrays, improving power generation efficiency; in distributed photovoltaic applications, such as household photovoltaic systems, the miniaturized and high - reliability PCB board enables the inverter to achieve a compact design, reducing the installation space requirement, while ensuring the high efficiency and stability of power conversion, promoting the wider integration of photovoltaic power generation into daily electricity consumption scenarios.

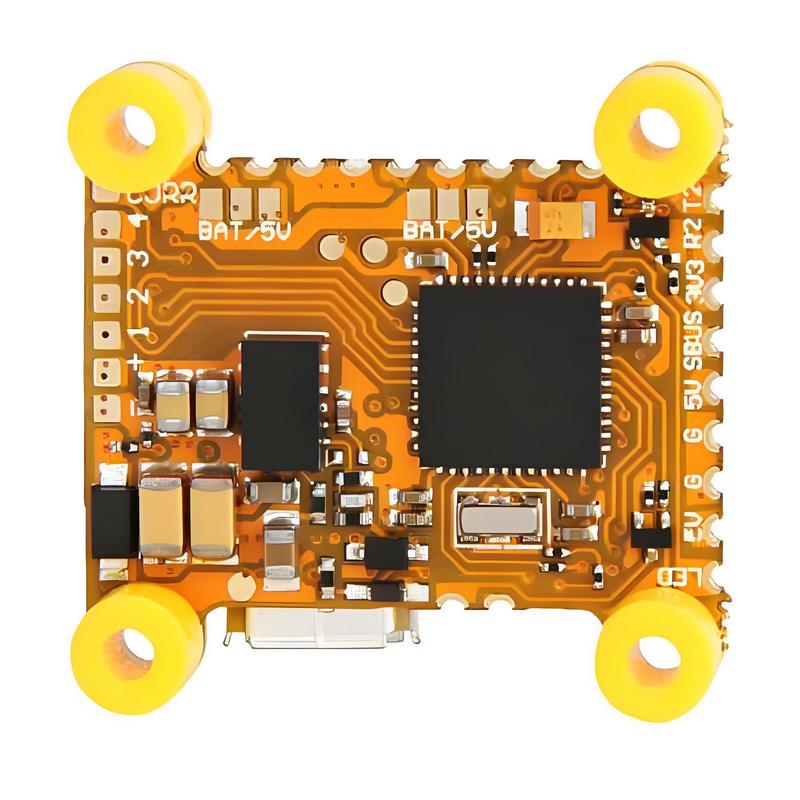

In the field of energy storage equipment, whether it is a lithium - ion battery energy storage system or the application of new energy storage technologies, the PCB board is crucial. In the lithium - ion battery management system (BMS), the PCB board integrates multi - parameter monitoring circuits such as voltage, current and temperature, and equalization control circuits, accurately collecting battery state data in real time, and realizing the charge - discharge equalization management of the battery pack through intelligent algorithms, extending the battery service life and ensuring the safe and stable operation of the energy storage system. For the power conversion system (PCS) of large - scale energy storage power stations, the high - power and high - integration PCB board undertakes the interconnection and control tasks of high - power power electronic devices, realizing the efficient conversion of AC and DC power, improving the charge - discharge efficiency of the energy storage system, and helping the power grid to peak - shaving, valley - filling and accept more renewable energy power.

In the new energy vehicle industry, the PCB board is even more ubiquitous. In the power control system of electric vehicles, the PCB board of the motor controller uses materials with high thermal conductivity and high strength to cope with the working environment of high power and high heat generation. Through the optimized power circuit design, it realizes the accurate speed regulation and efficient driving of the motor, improving the vehicle's endurance and power performance. The PCB board of the battery management system (BMS) monitors the state of the battery pack in real time to ensure the safe charge and discharge of the battery. In addition, in the intelligent driving assistance system, the vehicle - mounted entertainment and communication system, the PCB board, with high integration and high reliability, supports the coordinated work of various sensors, controllers and display devices, promoting the development of new energy vehicles towards intelligence and connectivity, continuously upgrading the green travel experience, and accelerating the energy transformation in the transportation field.

As the new energy industry continues to expand, from the intelligent control equipment of offshore wind power to the management system of hydrogen energy fuel cells, the PCB board continuously adapts to new scenarios and new demands, promoting the performance iteration of new energy equipment with technological innovation, and becoming a solid hardware cornerstone in the journey of green energy transformation, helping the global energy system to accelerate the transformation towards a cleaner, more efficient and more sustainable direction.

Related news