Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

Understanding Elevator Control PCB Assembly: A Key Component in Modern Elevators

2025-10-11

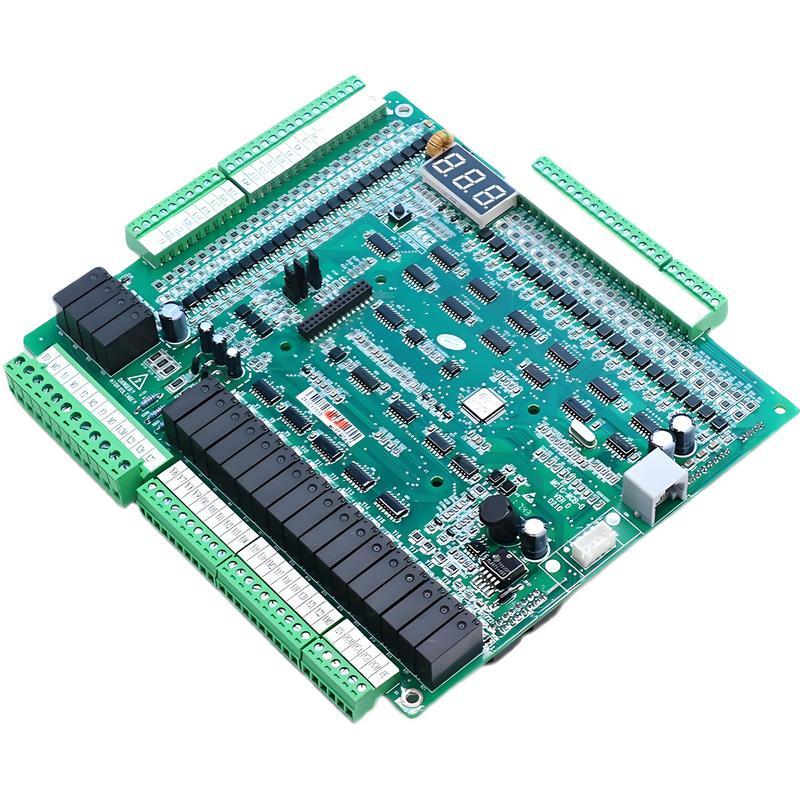

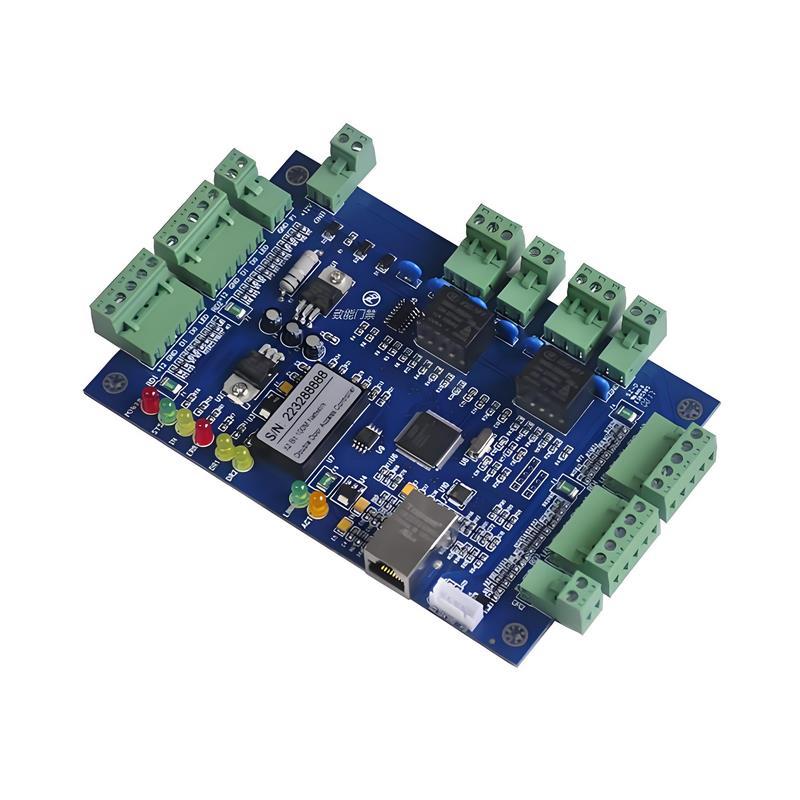

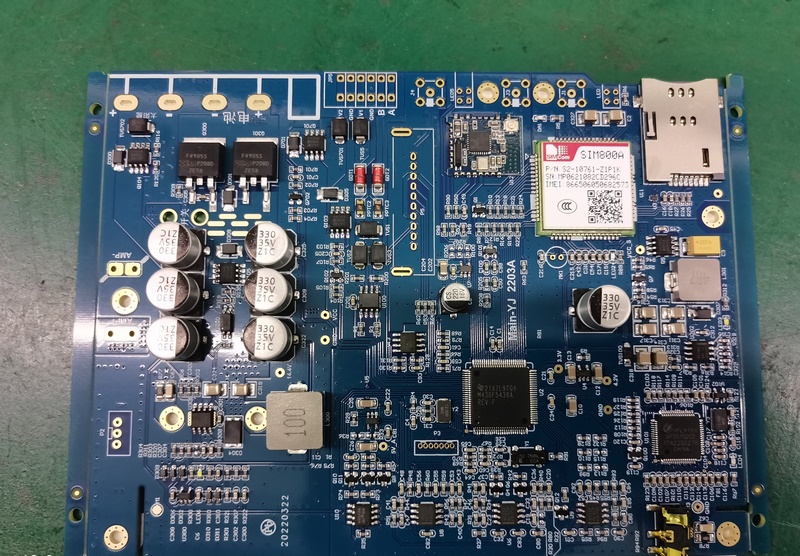

Elevators play a crucial role in modern architecture, enabling people to move swiftly between different floors of buildings. At the heart of these systems lies the Elevator Control PCB (Printed Circuit Board) Assembly. This component serves as the brain of the elevator system, orchestrating various functions to ensure seamless operation.

The Elevator Control PCB Assembly is responsible for managing the elevator's movement, door operations, and safety features. It receives input from various sensors, such as position sensors and load weighing sensors, and processes this information to make real-time decisions. This enables the elevator to stop at the correct floor, maintain safe speeds, and ensure that doors open and close safely.

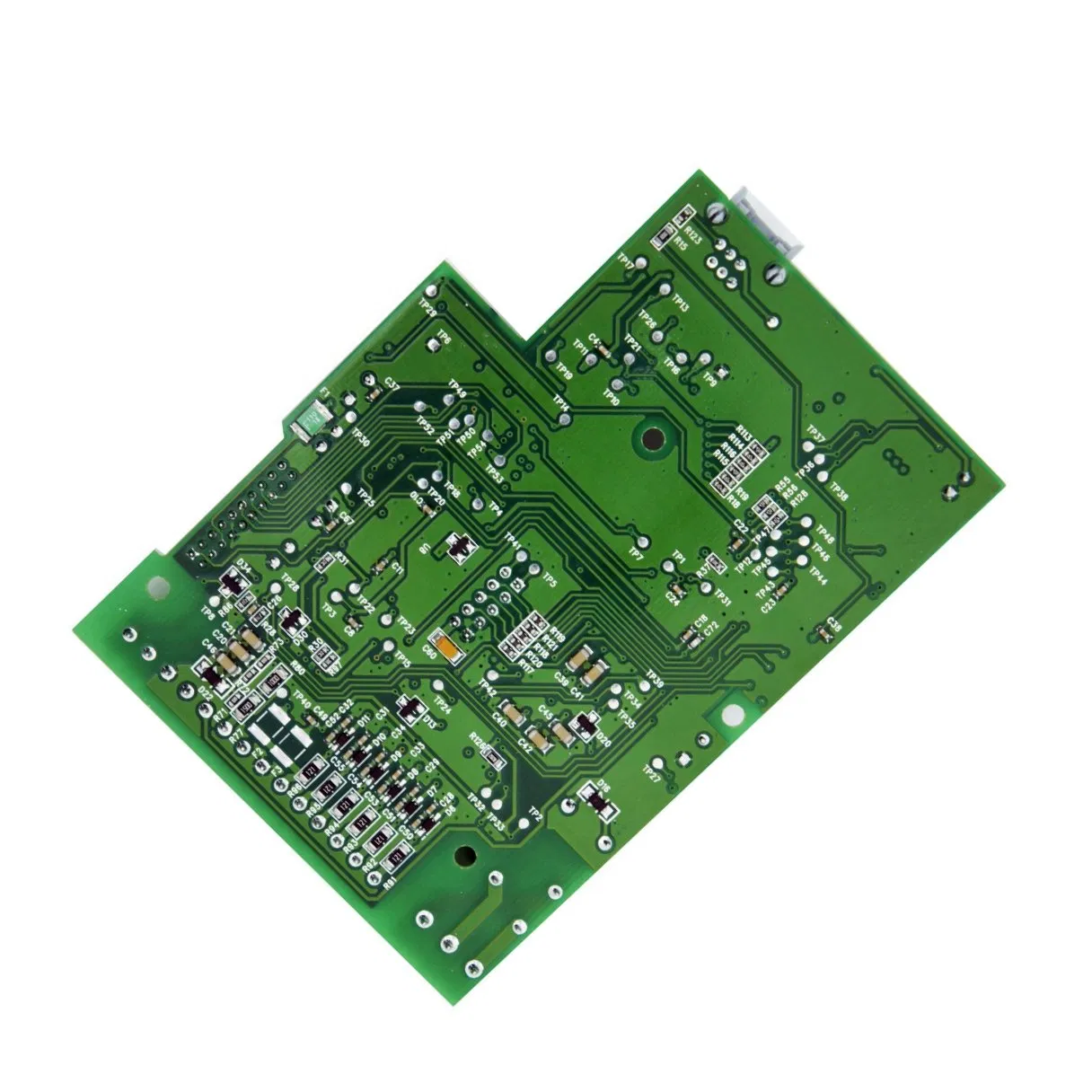

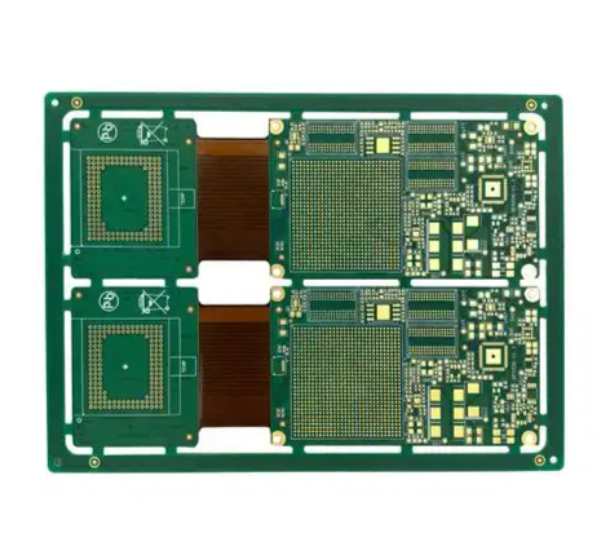

The manufacturing process of Elevator Control PCB Assembly involves several critical steps. First, the design phase is crucial, where engineers create schematic diagrams and layout designs that incorporate all necessary components. These designs must meet specific industry standards and safety regulations, ensuring reliability and performance.

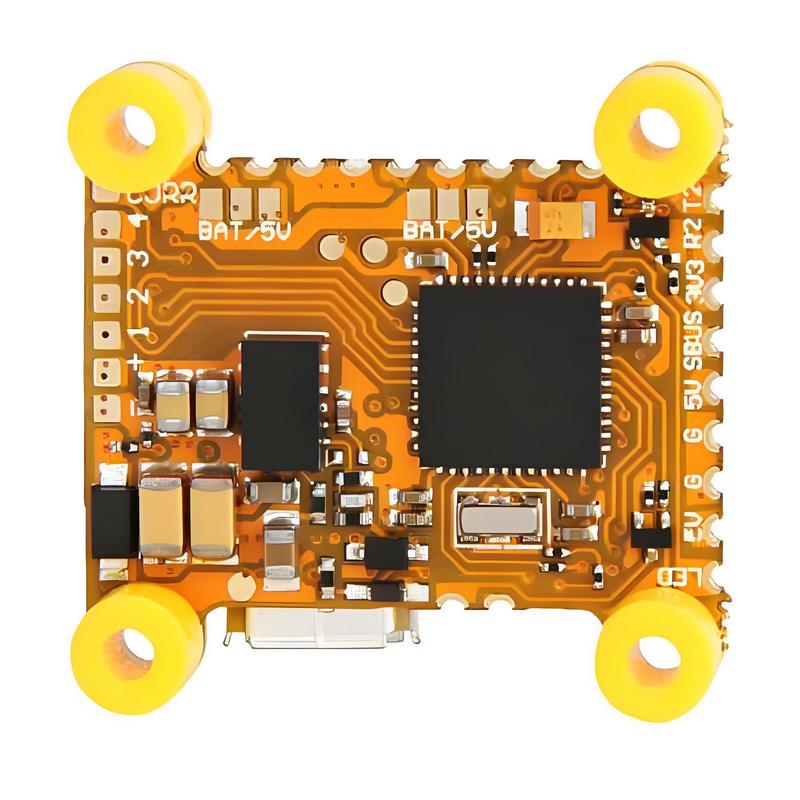

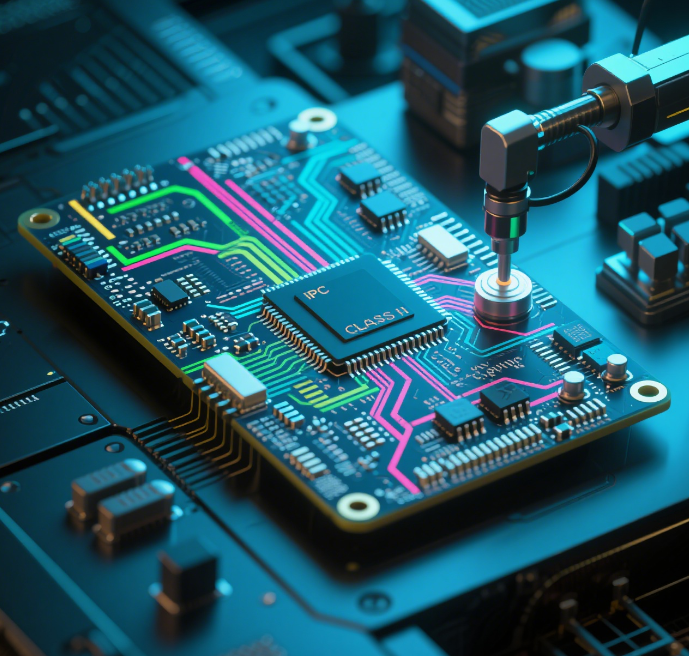

Once the design is finalized, the next step is fabrication. This involves the production of the PCB, where layers of conductive materials are etched onto a substrate. Following fabrication, the assembly process begins, involving the placement of electronic components like microcontrollers, resistors, and capacitors onto the board. This is typically done using automated pick-and-place machines, which enhance precision and efficiency.

After assembly, rigorous testing is performed to ensure that the Elevator Control PCB functions correctly under various conditions. This testing phase is vital as it checks for potential faults, ensuring the safety of the elevator system. Quality assurance is paramount in this industry, as any failure in the control system can lead to accidents and downtime.

The significance of Elevator Control PCB Assembly cannot be overstated. As buildings grow taller and more complex, the demand for advanced elevator systems increases. Modern elevators incorporate features such as smart controls, energy efficiency, and enhanced safety measures, all of which rely heavily on sophisticated PCB assemblies.

In conclusion, the Elevator Control PCB Assembly is a critical element in the operation of elevators, intertwining technology with safety and efficiency. Understanding its design and manufacturing process is vital for stakeholders in the electronic components industry, as it highlights the importance of quality and innovation in modern vertical transport systems. As we continue to innovate and improve these systems, the Elevator Control PCB will remain an integral part of our urban infrastructure.

The Elevator Control PCB Assembly is responsible for managing the elevator's movement, door operations, and safety features. It receives input from various sensors, such as position sensors and load weighing sensors, and processes this information to make real-time decisions. This enables the elevator to stop at the correct floor, maintain safe speeds, and ensure that doors open and close safely.

The manufacturing process of Elevator Control PCB Assembly involves several critical steps. First, the design phase is crucial, where engineers create schematic diagrams and layout designs that incorporate all necessary components. These designs must meet specific industry standards and safety regulations, ensuring reliability and performance.

Once the design is finalized, the next step is fabrication. This involves the production of the PCB, where layers of conductive materials are etched onto a substrate. Following fabrication, the assembly process begins, involving the placement of electronic components like microcontrollers, resistors, and capacitors onto the board. This is typically done using automated pick-and-place machines, which enhance precision and efficiency.

After assembly, rigorous testing is performed to ensure that the Elevator Control PCB functions correctly under various conditions. This testing phase is vital as it checks for potential faults, ensuring the safety of the elevator system. Quality assurance is paramount in this industry, as any failure in the control system can lead to accidents and downtime.

The significance of Elevator Control PCB Assembly cannot be overstated. As buildings grow taller and more complex, the demand for advanced elevator systems increases. Modern elevators incorporate features such as smart controls, energy efficiency, and enhanced safety measures, all of which rely heavily on sophisticated PCB assemblies.

In conclusion, the Elevator Control PCB Assembly is a critical element in the operation of elevators, intertwining technology with safety and efficiency. Understanding its design and manufacturing process is vital for stakeholders in the electronic components industry, as it highlights the importance of quality and innovation in modern vertical transport systems. As we continue to innovate and improve these systems, the Elevator Control PCB will remain an integral part of our urban infrastructure.

Related news

2025-09-30

Medical Electronics Pcb Assembly

2025-09-30

2025-09-30

2025-09-30

2025-09-30

Precision Instruments Pcb Assembly

2025-09-30