Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

Maximizing Efficiency: The Role of AI in PCB Assembly for Communication Devices

2025-10-02

Maximizing Efficiency: The Role of AI in PCB Assembly for Communication Devices

Table of Contents

- Introduction to AI in PCB Assembly

- Understanding PCB Assembly

- Importance of PCB in Communication Devices

- Challenges in the PCB Assembly Process

- Introduction of AI in PCB Assembly

- Benefits of AI in PCB Assembly

- Real-World Applications of AI in PCB Assembly

- The Future of AI in PCB Assembly

- Conclusion

- Frequently Asked Questions

Introduction to AI in PCB Assembly

The advent of artificial intelligence (AI) is transforming industries, and the **electronic components sector** is no exception. Within this sector, **Printed Circuit Board (PCB) assembly** is crucial, particularly for **communication devices**. AI technologies offer innovative solutions to improve **efficiency**, **accuracy**, and **quality control** in the PCB assembly process. This article delves into how AI maximizes efficiency in PCB assembly, addressing the inherent challenges and future implications for the industry.

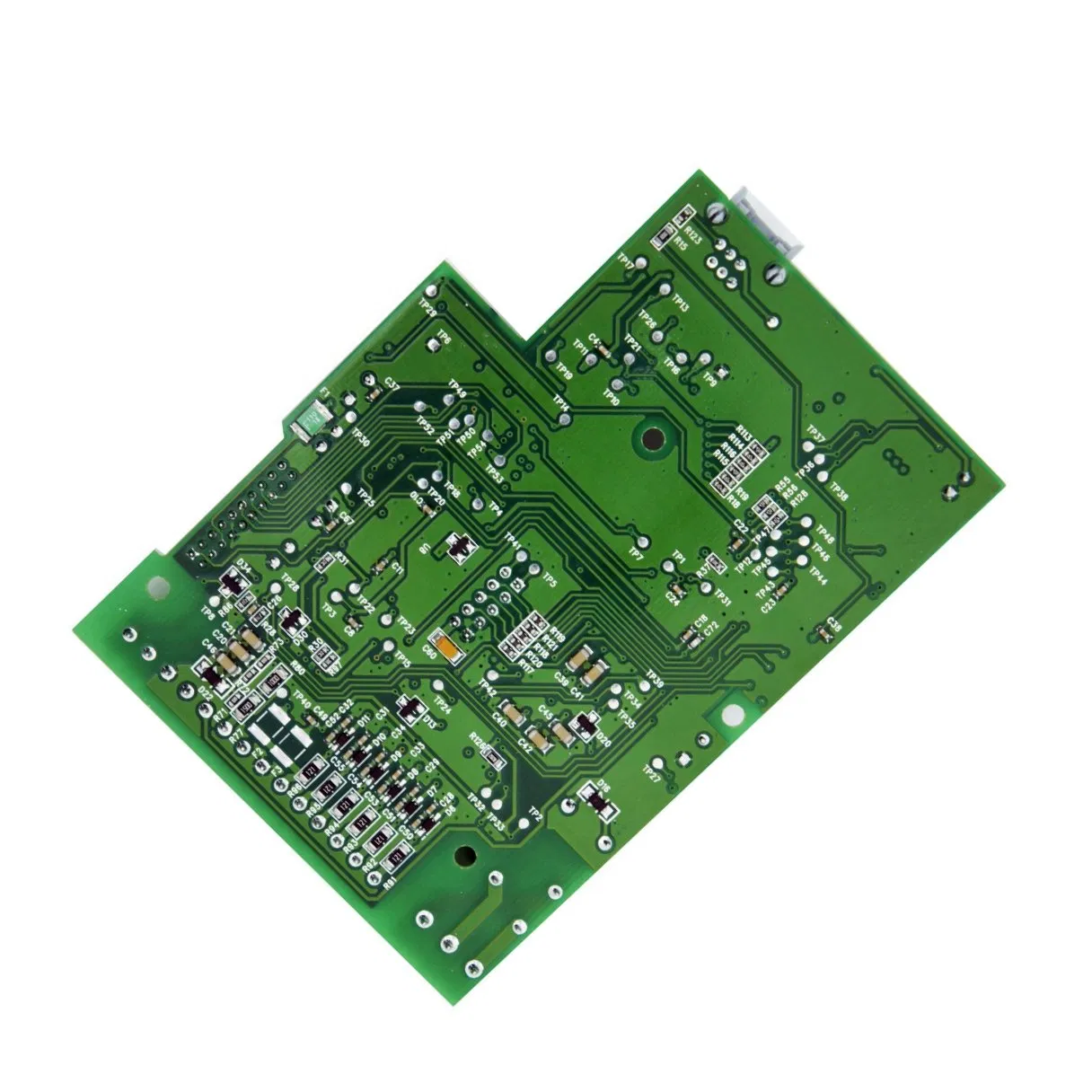

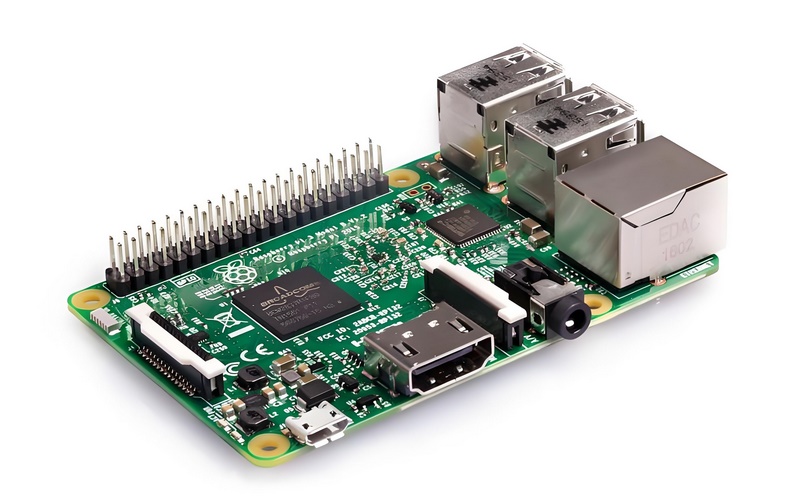

Understanding PCB Assembly

PCB assembly is the process of attaching various electronic components to a PCB to create an electronic device. Unlike traditional manufacturing methods, modern PCB assembly utilizes a combination of manual and automated processes. The goal is to create a reliable and functional electronic circuit that meets the performance specifications required by communication devices.

The PCB Assembly Process

The PCB assembly process typically involves several key steps:

1. **Design and Layout**: Engineers design the PCB layout using computer-aided design (CAD) software.

2. **Solder Paste Application**: Solder paste is applied to designated areas of the PCB to prepare it for the component placement.

3. **Component Placement**: Automated machines pick and place components onto the PCB.

4. **Soldering**: The assembly undergoes soldering, either through reflow or wave soldering methods.

5. **Inspection and Testing**: Quality assurance through visual inspection and automated testing ensures that each board meets specifications.

Importance of PCB in Communication Devices

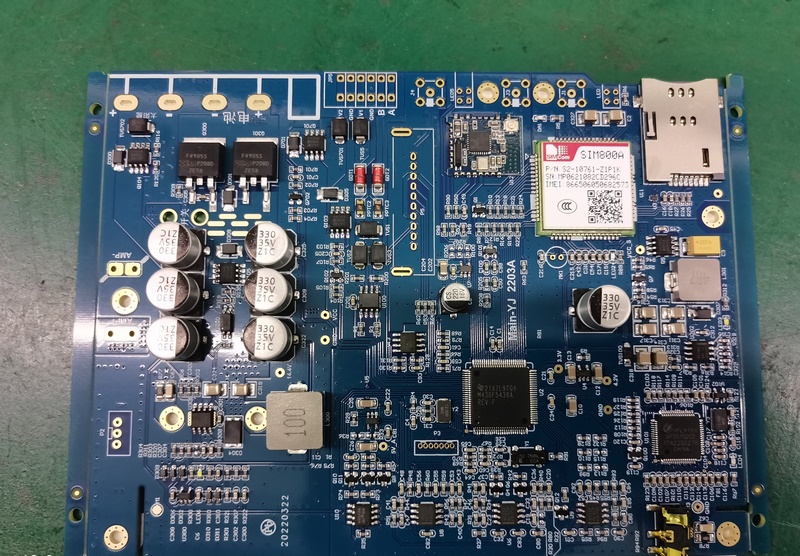

PCBs serve as the backbone of communication devices, including smartphones, tablets, routers, and other electronic systems. They enable efficient connectivity and signal transmission while housing the necessary components such as resistors, capacitors, and integrated circuits.

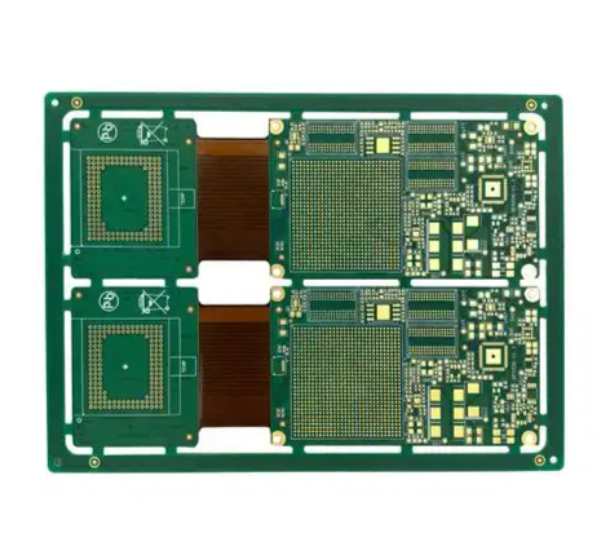

Role of PCBs in Communication Technology

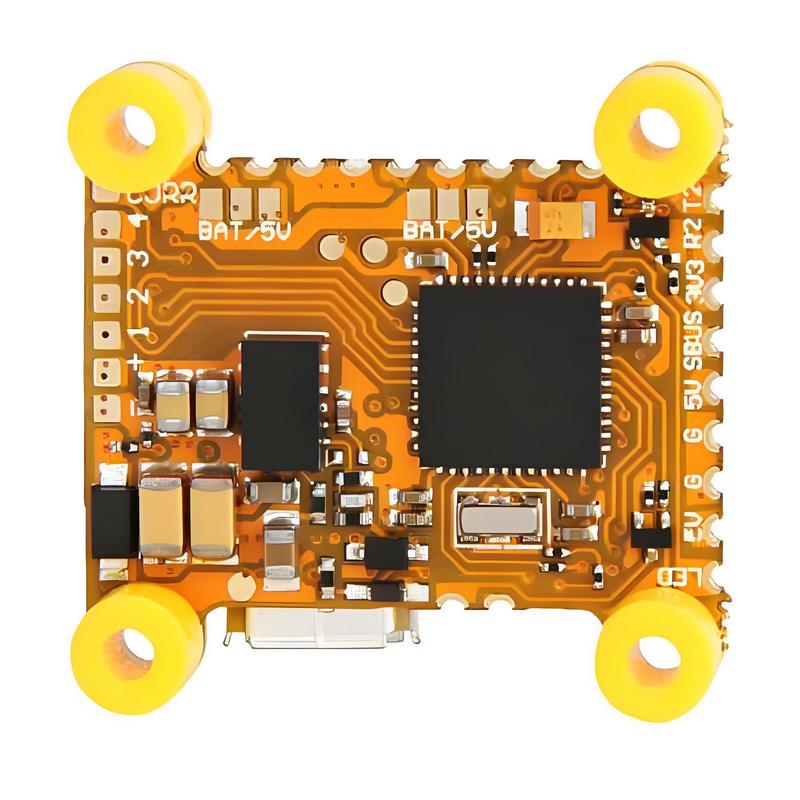

In communication technology, PCBs must optimize signal integrity, minimize interference, and allow for compact designs. As devices become more sophisticated, the demand for high-quality PCB assembly that adheres to strict standards continues to grow.

Challenges in the PCB Assembly Process

Despite advancements, the PCB assembly process faces numerous challenges:

- **Complex Designs**: As communication devices evolve, PCBs become more complex, making assembly more difficult.

- **Tight Tolerances**: Precision is required at every stage to prevent defects and ensure performance.

- **Supply Chain Issues**: Fluctuations in the availability of components can lead to delays and increased costs.

- **Quality Control**: Ensuring each PCB meets high-quality standards remains a significant challenge, particularly in high-volume production.

Introduction of AI in PCB Assembly

AI technologies, including machine learning, computer vision, and robotics, are revolutionizing the PCB assembly landscape. By integrating AI, manufacturers can streamline processes, reduce errors, and enhance productivity.

Machine Learning and Predictive Analytics

Machine learning algorithms analyze historical data to predict potential assembly failures or quality issues, allowing manufacturers to mitigate risks before they occur. This proactive approach to quality assurance saves time and resources.

Computer Vision Systems

AI-powered computer vision systems improve inspection processes by identifying defects that may be overlooked by the human eye. These systems use advanced algorithms to analyze images of PCBs and detect misalignments, soldering defects, and component placement errors.

Benefits of AI in PCB Assembly

The integration of AI into PCB assembly offers numerous benefits:

Enhanced Efficiency

AI-driven automation increases the speed of assembly processes, allowing manufacturers to produce more units within the same timeframe. This efficiency is particularly crucial in meeting the growing demand for communication devices.

Improved Accuracy and Quality

AI minimizes human error, ensuring that each component is placed and soldered correctly. The application of computer vision systems further enhances quality control by providing real-time feedback during the assembly process.

Cost Reduction

By reducing errors and optimizing workflows, AI contributes to lower production costs. Manufacturers can allocate resources more effectively, ultimately leading to savings that can be passed on to consumers.

Scalability

AI-driven systems can easily scale operations to accommodate varying production volumes. This flexibility allows manufacturers to respond swiftly to market fluctuations and demands.

Real-World Applications of AI in PCB Assembly

Several companies have successfully implemented AI technologies in their PCB assembly processes, showcasing tangible benefits.

Case Study: Company X

Company X, a leading manufacturer of communication devices, integrated AI-driven robotics into its assembly line. By utilizing machine learning algorithms, they reduced their defect rate by 30%, significantly improving overall product quality.

Case Study: Company Y

Company Y adopted advanced computer vision systems for real-time inspection. This implementation led to a 25% increase in assembly speed and a notable reduction in return rates due to defects.

The Future of AI in PCB Assembly

The future of AI in PCB assembly looks promising. As technology continues to evolve, we can expect further advancements in automation, quality control, and process optimization. Innovations such as collaborative robots (cobots) and more sophisticated algorithms will likely play a significant role in shaping the PCB assembly landscape.

Emerging Trends

1. **Hyper-Automation**: The increasing use of automation technologies will drive the efficiency of PCB assembly.

2. **Smart Manufacturing**: The emergence of Industry 4.0 will facilitate the integration of IoT devices, enabling real-time data analysis and decision-making.

3. **Sustainability**: AI will play a critical role in developing sustainable practices within the PCB assembly process, focusing on waste reduction and energy efficiency.

Conclusion

The integration of AI in PCB assembly represents a significant leap forward for the communication device industry. By enhancing efficiency, improving accuracy, and reducing costs, AI technologies are poised to redefine the landscape of electronic manufacturing. As we continue to explore the potential of AI, manufacturers must remain adaptable and open to innovation, ensuring they stay at the forefront of this rapidly evolving industry.

Frequently Asked Questions

1. What is PCB assembly?

PCB assembly is the process of attaching electronic components onto a printed circuit board to create functional electronic devices.

2. How does AI enhance PCB assembly?

AI enhances PCB assembly by automating processes, improving quality control, and minimizing errors, thereby increasing efficiency and accuracy.

3. What are some challenges in PCB assembly?

Challenges include complex designs, maintaining tight tolerances, managing supply chain issues, and ensuring quality control.

4. Can AI reduce production costs in PCB assembly?

Yes, by streamlining processes and reducing errors, AI contributes to lower production costs, allowing manufacturers to be more competitive.

5. What does the future hold for AI in PCB assembly?

The future of AI in PCB assembly includes advancements in automation, smart manufacturing, and sustainable practices, leading to increased efficiency and innovation in the industry.

Related news

2025-09-30

Medical Electronics Pcb Assembly

2025-09-30

2025-09-30

2025-09-30

2025-09-30

Precision Instruments Pcb Assembly

2025-09-30

Facial Recognition Pcb Assembly

2025-09-30

2025-09-30

Communication And Aiot Pcb Assembly

2025-09-30