Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

Mastering UAV PCB Assembly: A Comprehensive Guide to Success

2025-10-05

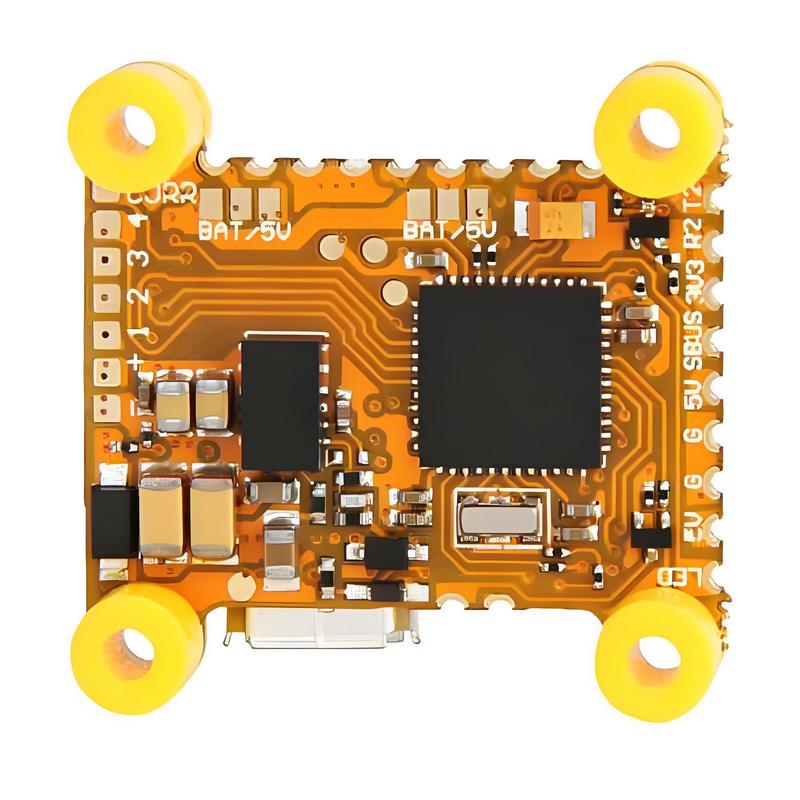

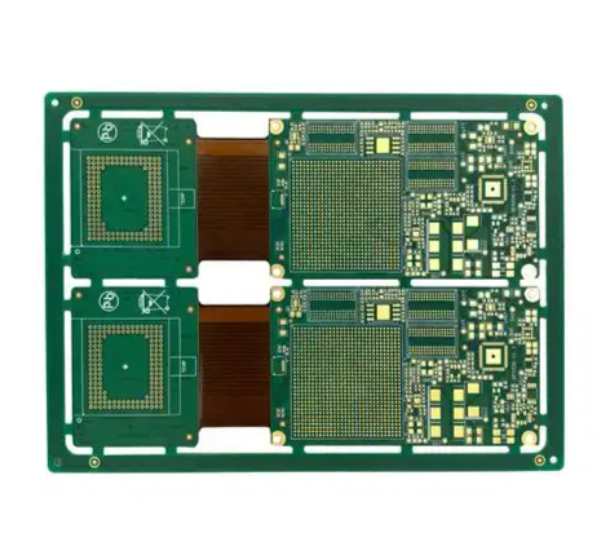

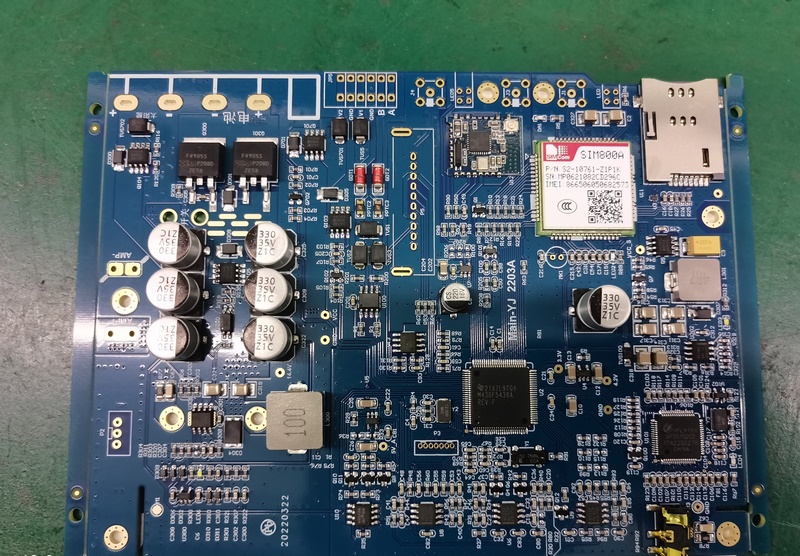

At its core, UAV PCB assembly encompasses several vital steps that ensure the reliable functionality of drones and other UAVs. The process begins with the design of the PCB, which must meet specific requirements tailored to the UAV's performance objectives. Factors such as weight, size, and environmental conditions play crucial roles in the design phase. Advanced software tools are often employed to simulate the circuit's performance, allowing engineers to optimize the layout before moving forward.

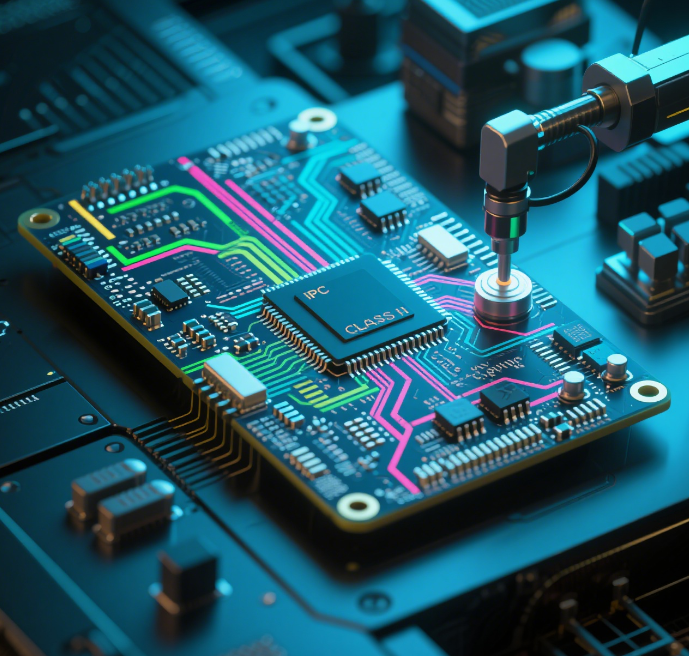

Once the design is finalized, the assembly process can commence. This typically involves the placement of components onto the PCB, which can be performed using manual methods or automated assembly machines. For UAVs, precision is paramount; any misalignment can lead to performance issues. Therefore, meticulous attention to detail during this stage cannot be overstated.

After the components are placed, soldering is the next critical step. This process involves joining electrical components to the PCB through soldering techniques, which can range from wave soldering to reflow soldering, depending on the design and component types. The choice of soldering method may influence the overall reliability and durability of the UAV.

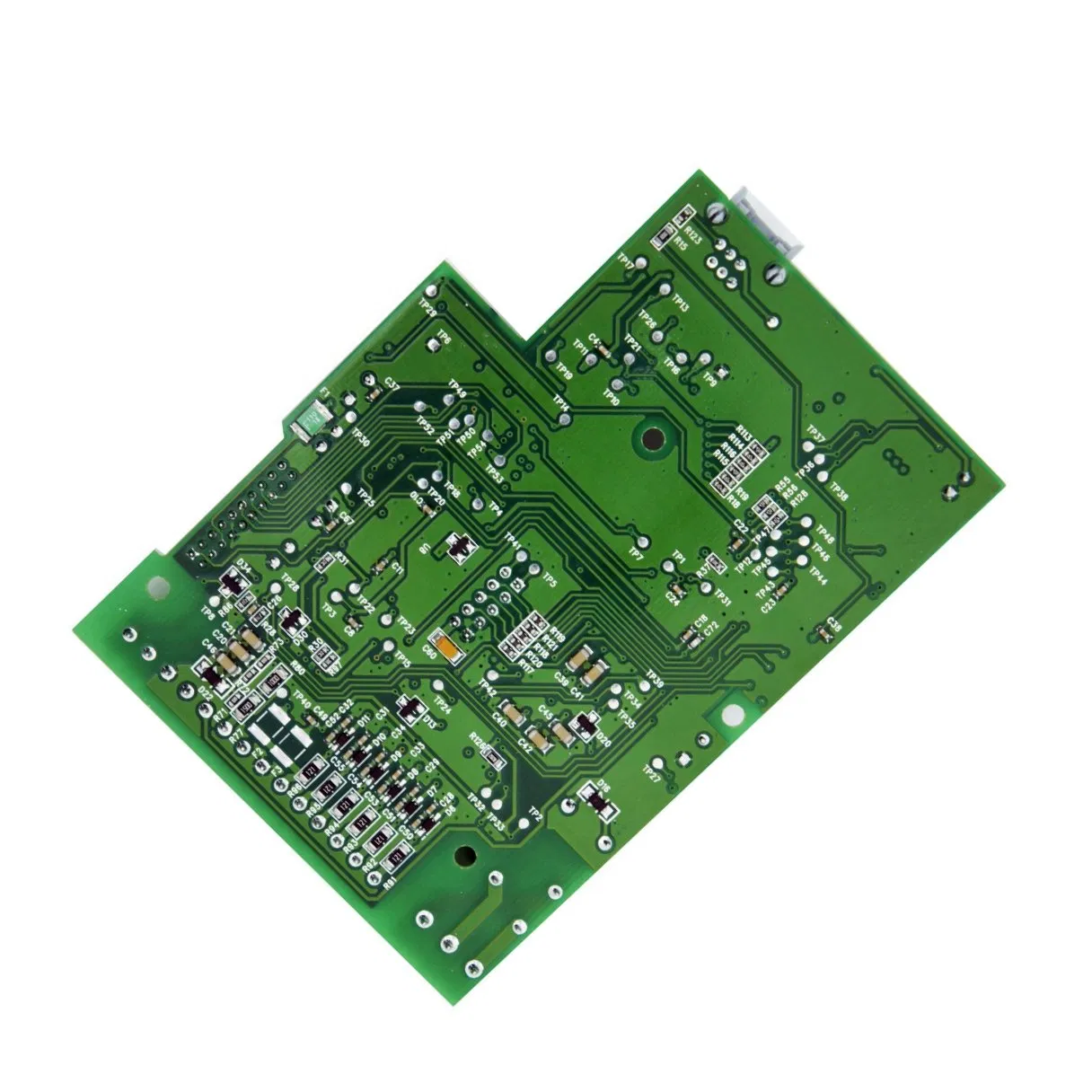

Testing is a crucial phase within UAV PCB assembly. Rigorous testing protocols must be implemented to ensure that each PCB meets quality standards and functions correctly under various conditions. This can include functional testing, thermal cycling, and vibration testing, simulating the real-world conditions the UAV will face during operation.

Another important aspect of UAV PCB assembly is compliance with industry standards. Adhering to regulations ensures that the PCBs are safe for use and can withstand the stresses of flight. Familiarity with relevant certifications, such as IPC standards, can be invaluable for those involved in the assembly process.

In conclusion, UAV PCB assembly is a multifaceted process that combines design, precision manufacturing, and rigorous testing to produce reliable and efficient circuit boards for unmanned aerial vehicles. By understanding the intricacies of this assembly process, professionals in the electronic components industry can enhance their product offerings and contribute to the ongoing advancement of UAV technology. Embracing best practices and staying informed about industry trends will ultimately drive success in this dynamic field.

Related news

2025-09-30

Medical Electronics Pcb Assembly

2025-09-30

2025-09-30

2025-09-30

2025-09-30

Precision Instruments Pcb Assembly

2025-09-30

Facial Recognition Pcb Assembly

2025-09-30

2025-09-30