Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

Unlocking the Potential of Facial Recognition with Efficient PCB Assembly

2025-10-08

Unlocking the Potential of Facial Recognition with Efficient PCB Assembly

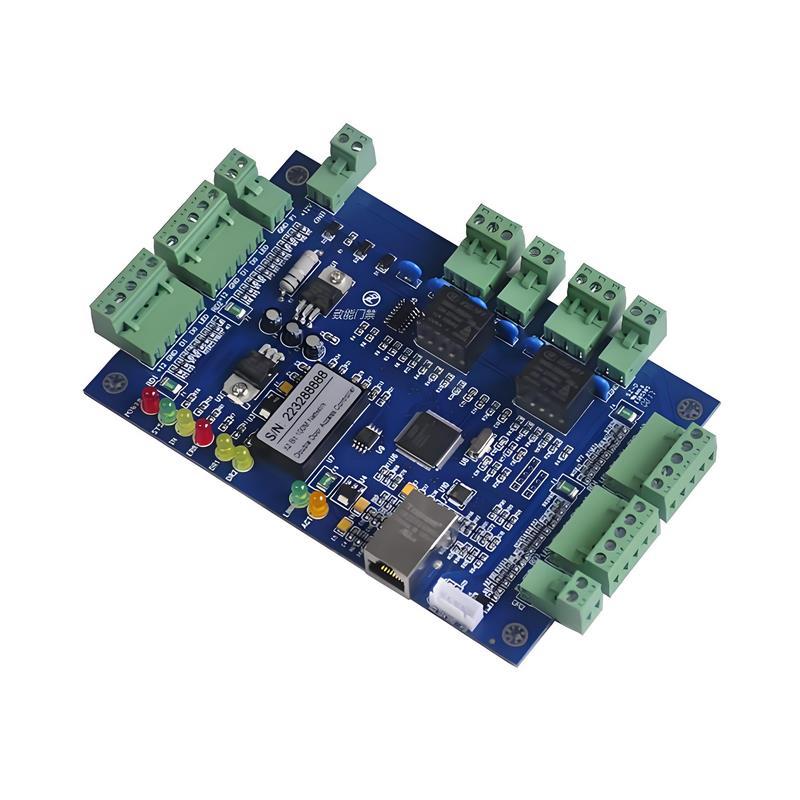

Facial recognition technology has rapidly evolved, becoming an integral part of various industries ranging from security to retail. At the heart of this technology lies the Printed Circuit Board (PCB) assembly, which serves as the backbone for its operation. In this article, we will delve into how efficient PCB assembly enhances facial recognition systems, the challenges faced, and potential solutions to maximize performance.

Table of Contents

1. Introduction to Facial Recognition Technology

2. The Importance of PCB Assembly in Facial Recognition

3. Challenges in PCB Assembly for Facial Recognition

4. Solutions for Efficient PCB Assembly

5. Future Trends in Facial Recognition and PCB Assembly

6. Case Studies: Successful Implementations

7. Frequently Asked Questions

8. Conclusion

Introduction to Facial Recognition Technology

Facial recognition technology utilizes algorithms to identify and verify individuals by analyzing their facial features. This biometric technology is extensively used in various applications, including security surveillance, mobile authentication, and even in social media platforms. As the demand for more precise and efficient facial recognition systems increases, the role of PCB assembly becomes increasingly significant.

The Importance of PCB Assembly in Facial Recognition

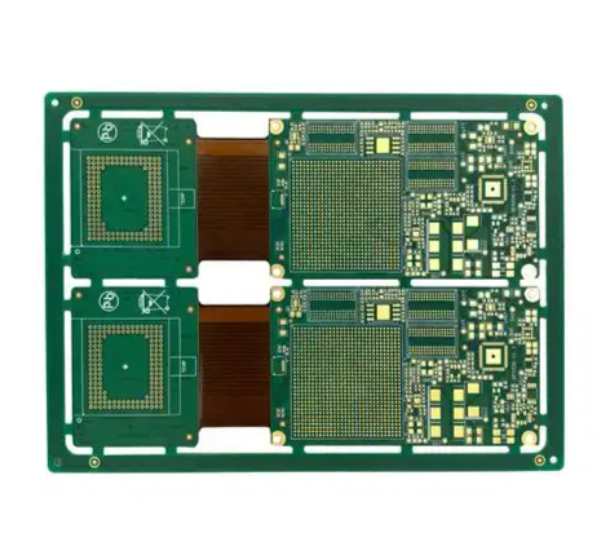

PCB assembly is critical for facial recognition systems as it integrates various electronic components needed for high performance. Here are a few reasons why efficient PCB assembly is vital for these systems:

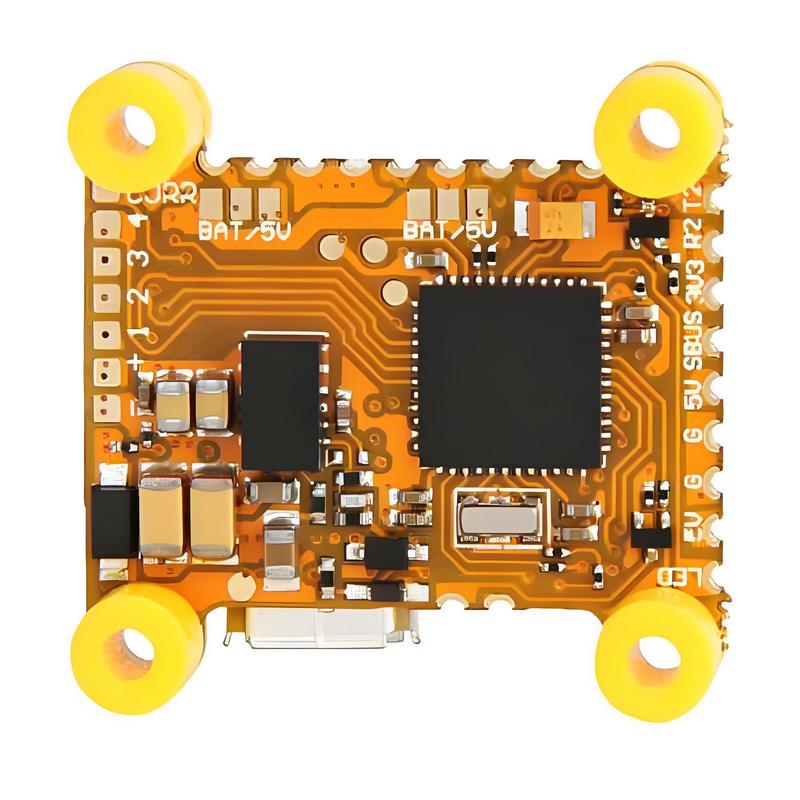

Miniaturization and Space Optimization

Efficient PCB assembly allows manufacturers to create smaller, more compact designs that save space. This miniaturization is essential for integrating advanced facial recognition systems into mobile devices and other compact hardware.

Performance Enhancement

High-quality PCB assembly ensures that the electronic components, such as sensors and processors, function optimally. This leads to faster processing times and improved accuracy in facial recognition tasks.

Cost-Effectiveness

By streamlining the PCB assembly process, manufacturers can reduce production costs, allowing for more competitive pricing of facial recognition systems. This cost-effectiveness can drive wider adoption across various sectors.

Challenges in PCB Assembly for Facial Recognition

Despite its importance, the PCB assembly process for facial recognition technology faces several challenges:

Complex Designs

Facial recognition systems often require complex PCB designs that can integrate various components efficiently. Designing these PCBs can be a daunting task, often leading to potential errors and delays.

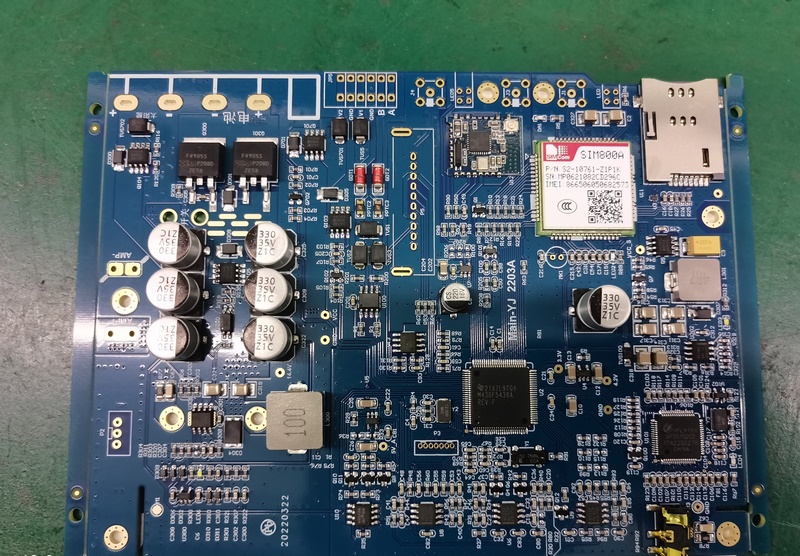

Heat Dissipation Issues

Facial recognition systems require powerful processors to operate. These processors generate heat, which can affect the performance of the PCB. Effective heat management solutions must be implemented during assembly.

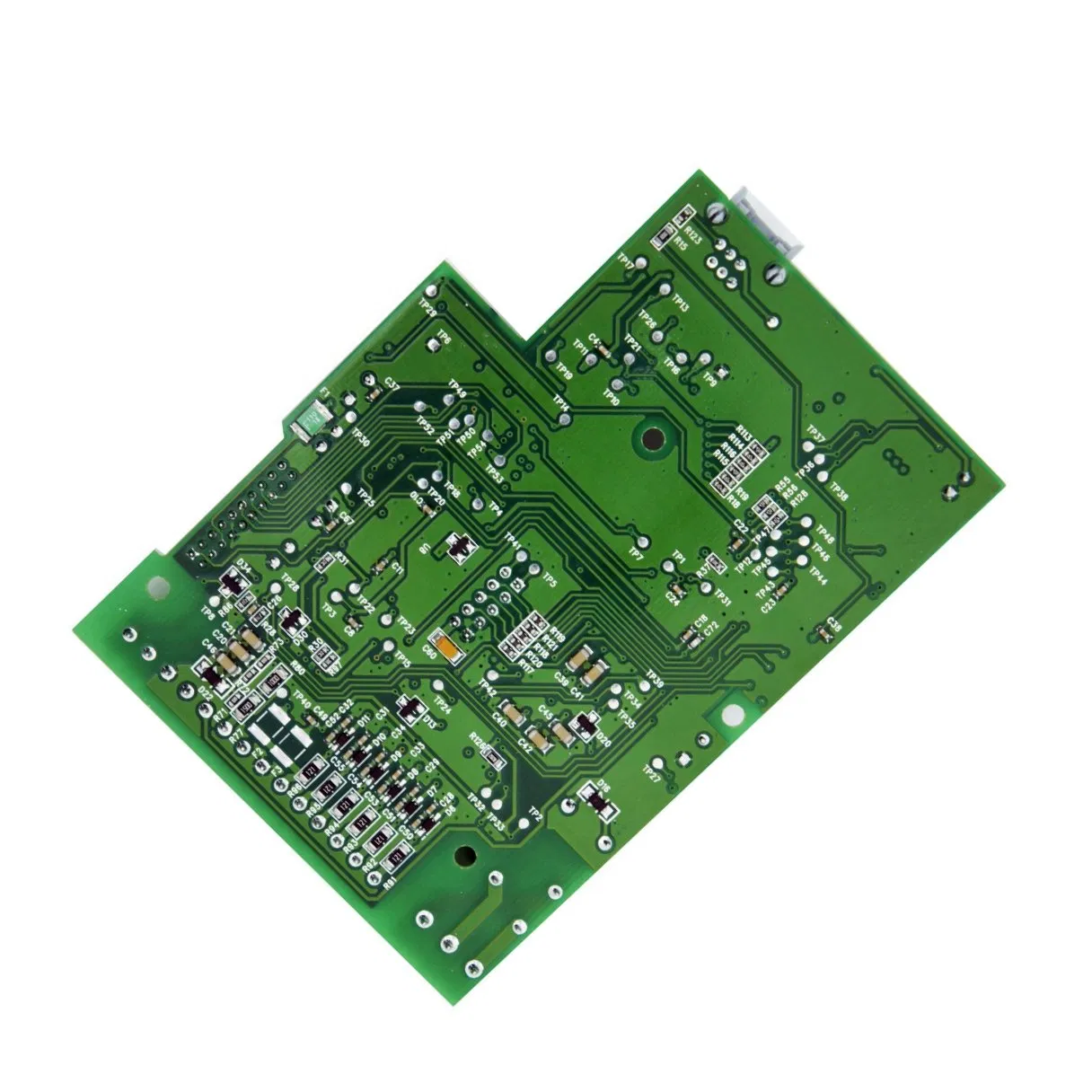

Quality Control

Ensuring the quality of each PCB component is crucial as even minor defects can lead to significant failures in facial recognition accuracy. Maintaining strict quality control standards is essential.

Solutions for Efficient PCB Assembly

To overcome the challenges mentioned, several solutions can be implemented:

Advanced Manufacturing Techniques

Utilizing advanced manufacturing techniques such as Surface Mount Technology (SMT) can enhance the efficiency of PCB assembly. SMT allows for the placement of components directly onto the surface of the PCB, resulting in smaller designs and reduced assembly time.

Thermal Management Solutions

Incorporating thermal management solutions, such as heat sinks and thermal pads, can help dissipate heat effectively. This ensures that the processors operate within safe temperature ranges, maintaining system performance.

Regular Quality Audits

Implementing regular quality audits throughout the PCB assembly process helps identify and rectify defects before they escalate. This proactive approach can significantly improve the reliability of facial recognition systems.

Future Trends in Facial Recognition and PCB Assembly

As technology evolves, so do the trends in facial recognition and PCB assembly:

AI Integration

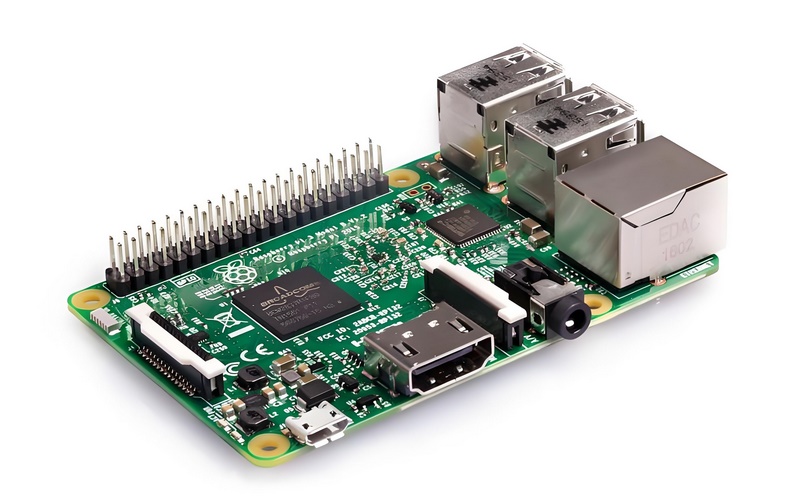

Artificial Intelligence (AI) is being increasingly integrated into facial recognition systems, enhancing their accuracy and efficiency. PCBs will need to be designed to accommodate AI chips that can process complex algorithms.

Edge Computing

The rise of edge computing allows facial recognition systems to process data locally rather than relying on cloud computing. This shift requires efficient PCB designs capable of handling higher processing loads while minimizing latency.

Increased Security Measures

With rising concerns over privacy and data security, future PCB designs will need to incorporate advanced security measures to protect sensitive data processed by facial recognition systems.

Case Studies: Successful Implementations

To illustrate the impact of efficient PCB assembly on facial recognition technology, let's explore a few case studies:

Case Study 1: Security Surveillance

A leading security firm revamped its surveillance systems by investing in advanced PCB assembly techniques. The result was a significant increase in the accuracy of facial recognition, reducing false positives by 25%. This improvement bolstered their market position and client satisfaction.

Case Study 2: Mobile Applications

A smartphone manufacturer integrated facial recognition technology into its latest model. By utilizing efficient PCB assembly, they achieved a compact design that enhanced performance without compromising battery life, leading to impressive sales figures.

Frequently Asked Questions

What is PCB assembly?

PCB assembly is the process of connecting electronic components to a printed circuit board, allowing it to perform its intended function.

How does facial recognition technology work?

Facial recognition technology analyzes facial features through algorithms that compare captured images with a database of known faces.

What challenges do manufacturers face in PCB assembly for facial recognition?

Manufacturers often face challenges such as complex designs, heat dissipation issues, and the need for strict quality control.

Why is efficient PCB assembly important for facial recognition systems?

Efficient PCB assembly enhances performance, reduces costs, and allows for miniaturization, which is crucial for integrating facial recognition into various devices.

What future trends can we expect in facial recognition technology?

Future trends include AI integration, edge computing, and enhanced security measures within PCB designs.

Conclusion

The integration of efficient PCB assembly into facial recognition technology is a key factor in unlocking its potential. By addressing challenges through advanced manufacturing techniques, effective thermal management, and stringent quality control, manufacturers can significantly enhance the performance and application of facial recognition systems. As this technology continues to evolve, staying ahead of trends will ensure that PCB assembly practices align with the growing demands of the industry. Embracing these changes will not only lead to better products but also foster consumer trust and satisfaction in this innovative technology.

Related news

2025-09-30

Medical Electronics Pcb Assembly

2025-09-30

2025-09-30

2025-09-30

2025-09-30

Precision Instruments Pcb Assembly

2025-09-30

Facial Recognition Pcb Assembly

2025-09-30