Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

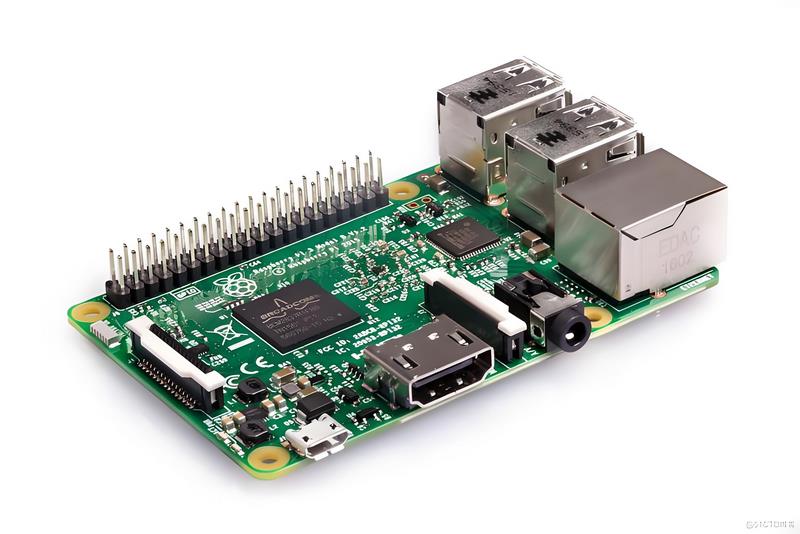

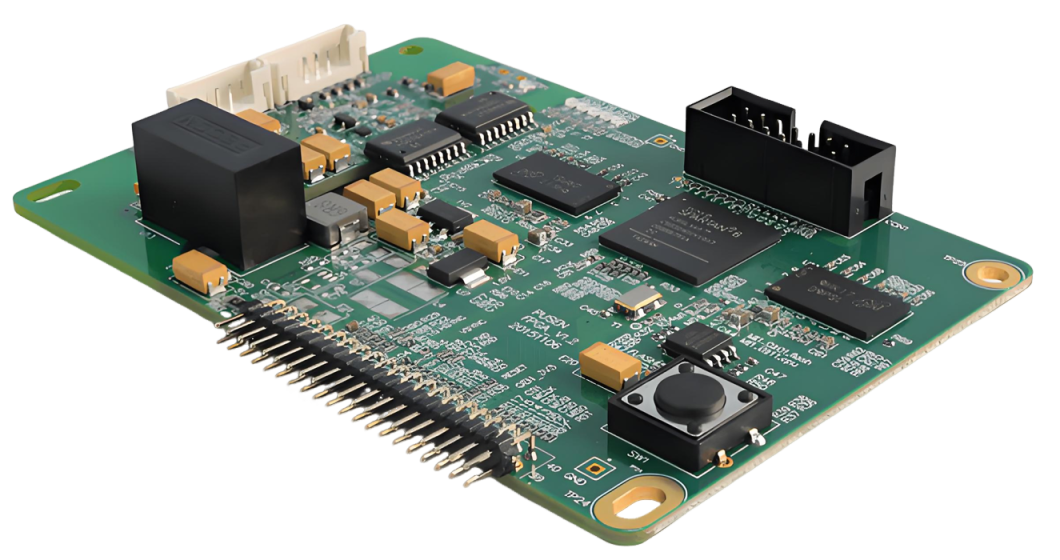

One-stop PCBA/EMS Intelligent Manufacturing Solution

PCB Design & Fabrication

High multi-layer (4-32 layers), HDI, rigid-flex boards, semiconductor test boards, etc.

Product Application Areas

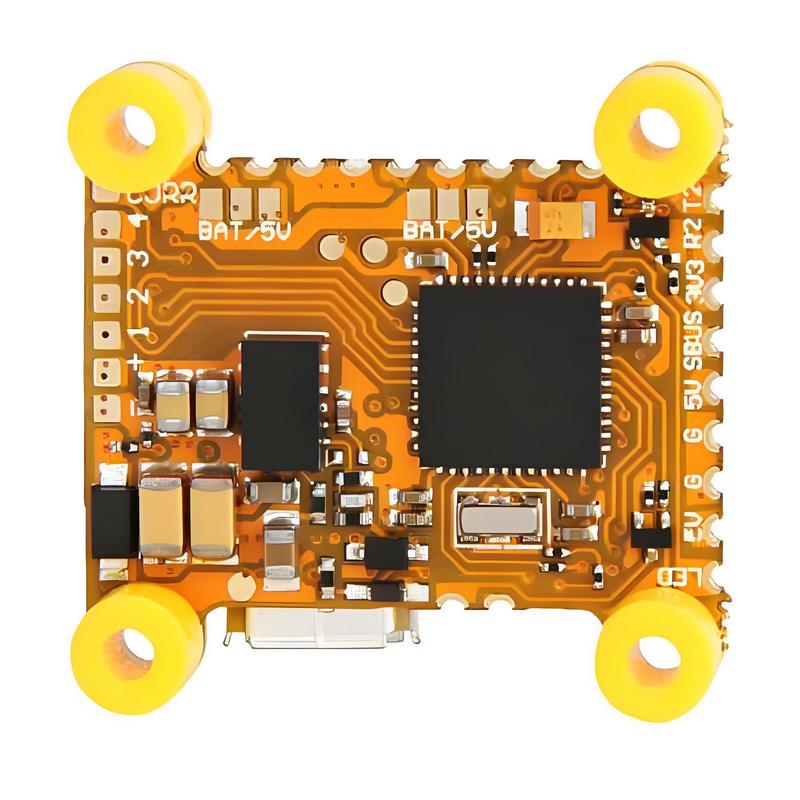

Communication and AIoT

5G core boards, WIFI/BLE modules, GNSS positioning modules

New energy and automotive electronics

BMS control boards, in-vehicle charging modules, sensor PCBAs

Medical electronics

Monitoring devices, diagnostic instruments, wearable medical hardware

Smart Home and Consumer Electronics

Smart controllers, AI voice interaction modules, IoT gateways

About Us

Established in 2017,Guangzhou Ruiyan Electronic Technology Co., Ltd. (EdgePCBA)is an enterprise specializing in EMS manufacturing services for electronic products. Our company offers one-stop turnkey PCB assembly services such as research and development,material procurement,SMT surface mount processing, DIP plug-in post soldering, PCBA testing aging, and finished product assembly.We specialize in small and medium volume production and ensure fast delivery. Our products are widely used in Communication and AIoT,New Energy and Automotive,Medical Electronics,Smart Home and Consumer Electronics,Industrial Control,Power Control,etc.

Learn MoreWhy Choose Us

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

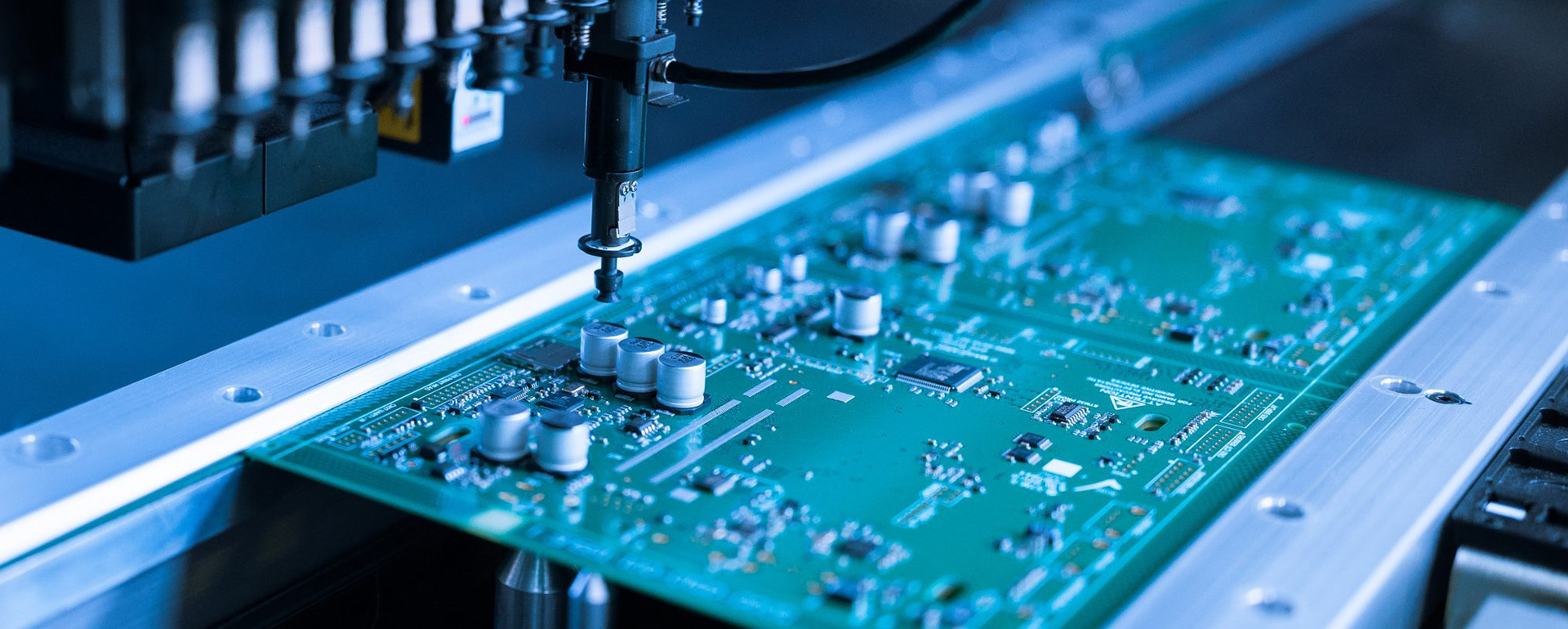

Technology Driven Intelligent Manufacturing

Equipped with 6 fully automated high-speed SMT placement lines (accuracy ±0.025mm), 2 DIP intelligent insertion lines and AOI/SPI/X-RAY inspection system, it supports the placement of precision components such as 01005, QFN, BGA, etc., with a daily placement capacity of 20 million points.

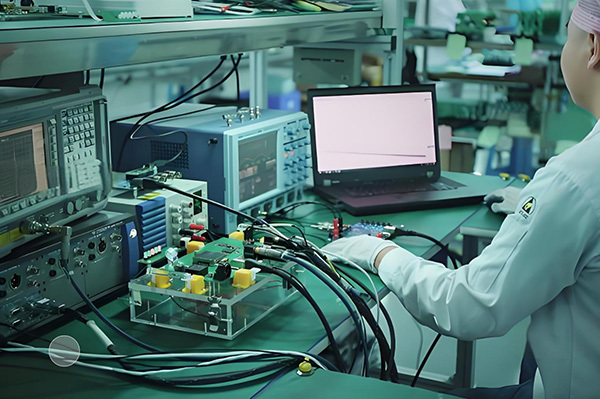

Full-process quality control

Passed ISO9001:2015 quality management system certification, implemented IPC-A-610G Class 2/3 standard, integrated MES traceability system to ensure full traceability from incoming material inspection to finished product delivery.

In-depth industry experience

The management team has been deeply engaged in the electronics manufacturing field for more than 10 years, successfully serving customers in 30+ countries around the world, and has mature process and reliability verification cases in 5G communication modules, PCBA for medical devices, and ECU control boards for automobiles.

Agile Service Network

Relying on the advantages of the Pearl River Delta electronics industry chain cluster, we provide 48-hour rapid prototyping, small- and medium-lot flexible production, and large-scale OEM/ODM services, and support multi-national compliance certifications such as RoHS and REACH.