Ask For A Quick Quote

We will contact you within one working day. Please pay attention to your email.

Request a Sample

With the mission of “Smart Manufacturing - Global Delivery”, we help our customers shorten the time-to-market and optimize the supply chain cost through continuous technology iteration and digital upgrading. We look forward to working with you to define the future of electronic manufacturing!

- Technology Driven Intelligent Manufacturing

- Full-process quality control

- In-depth industry experience

- Agile Service Network

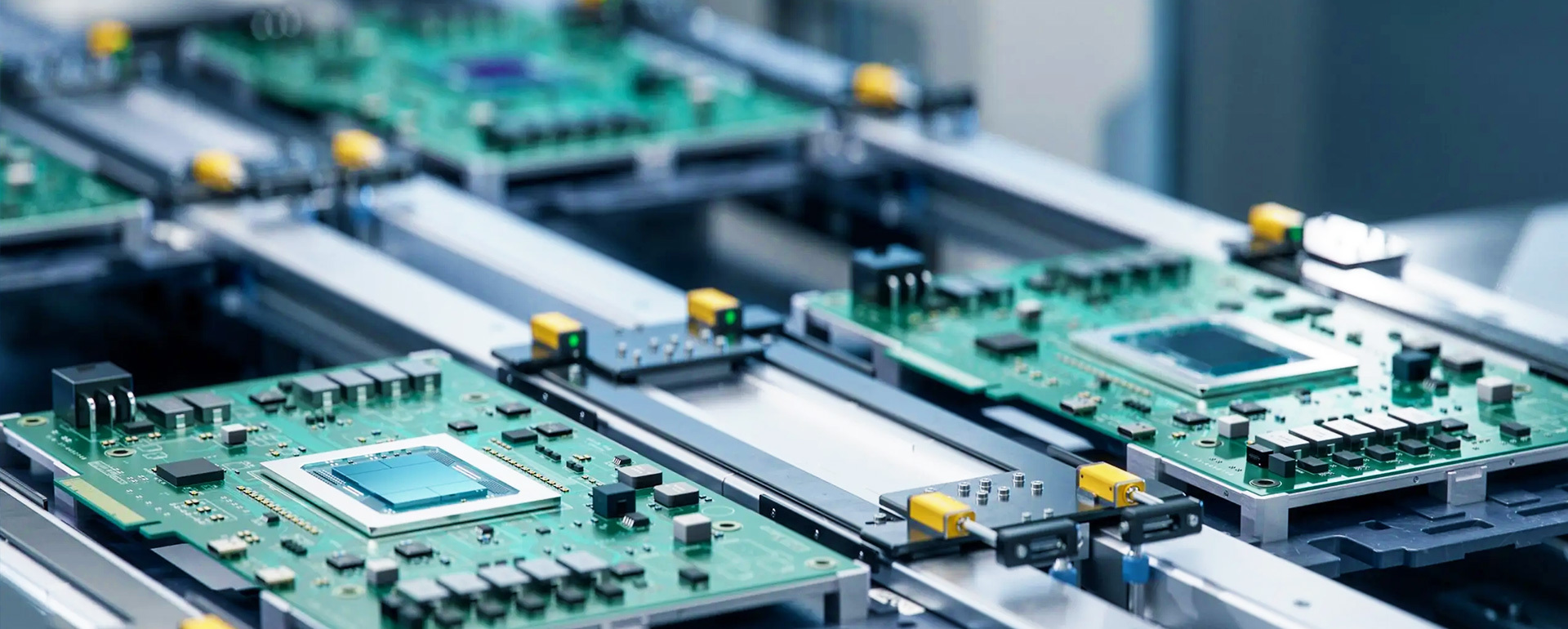

PCBA

One-stop PCBA/EMS Intelligent Manufacturing Solution

Testing

We understand that testing is a critical step in the PCBA (Printed Circuit Board Assembly) process to ensure the functionality, reliability, and quality of every assembled board. Our comprehensive PCBA testing services help detect potential defects early, reduce failure rates, and guarantee performance consistency before delivery.

We offer a wide range of testing methods tailored to your product requirements, including:

|

Our Testing Capabilities

|

Key Benefits

Our testing processes are fully integrated into our PCBA production workflow, enabling end-to-end quality control and giving you confidence that every board meets your exact specifications.

01Improve product reliability and reduce field returns |

02Ensure 100% functionality before shipment |

03Support for customer-specific test procedures and fixtures |

04Traceable test reports and detailed inspection records |

05Compliant with IPC and ISO quality standards |

Factory display

Company Reception

Exhibition Area

Office Area

Bulletin Board

Conference room

DIP Assembly Workshop

SMT Assembly Workshop

SMT Assembly Workshop

SMT Assembly Workshop

SMT Assembly Workshop

SMT Assembly Workshop

SMT Assembly Workshop

Cookie

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

Cookie

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Request A Quote

Please feel free to contact us at any time, and we will wholeheartedly provide you with the highest quality service and support.